Flexible automatic forging production line and working process thereof

A production line and flexible technology, applied in the field of forging processing, can solve the problems of high degree of freedom and low efficiency in handling workpieces, and achieve the effects of low labor intensity, high return on investment and good versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

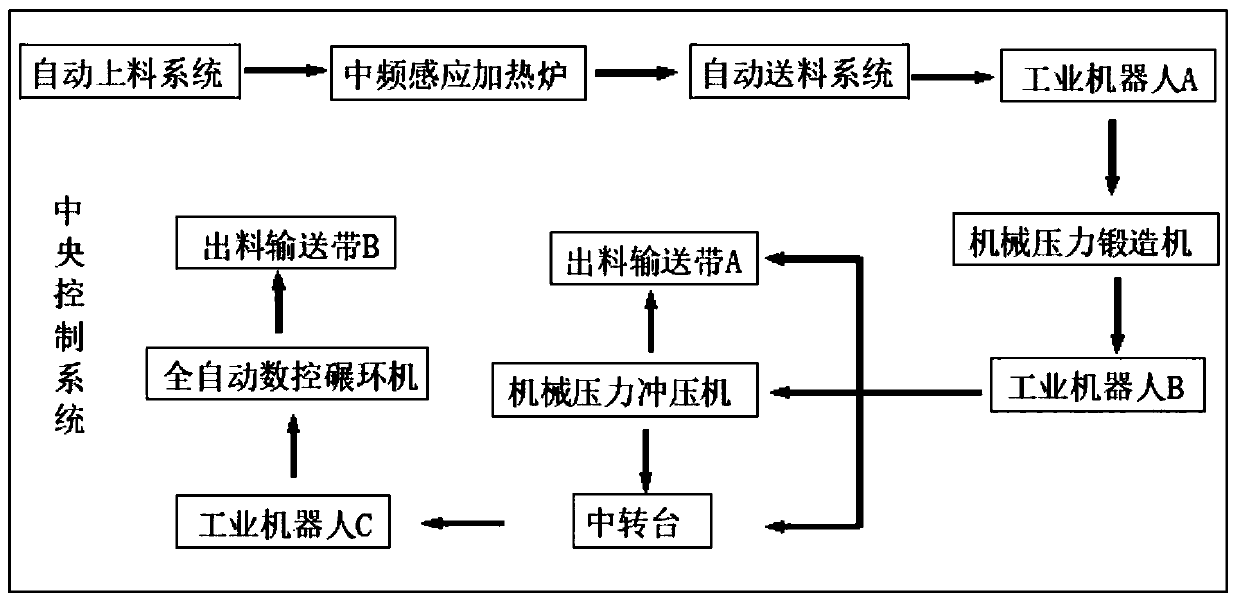

[0033] A flexible automatic forging production line, including upper and lower production areas, the lower production area is the operation area, and the upper production area is the control area. During construction, the operation area can have two safety doors, one for entering the operation area and one for entering by stairs Control area, the two areas do not communicate with each other to ensure safety;

[0034] The operation area includes an intermediate frequency induction heating furnace, a mechanical press forging press, a mechanical press, a fully automatic numerical control ring rolling machine, an automatic feeding system, an automatic feeding system, an output conveying system, and an industrial robot handling system. Including the central control system, the medium frequency induction heating furnace, mechanical press forging press, mechanical press, fully automatic CNC ring rolling machine, automatic feeding system, automatic feeding system, discharging conveying...

Embodiment 2

[0040] A forging production line (general forging), adopts the flexible automatic forging production line described in claim 4, and the operation process is as follows:

[0041] 1) Pre-set the production cycle of the medium frequency induction heating furnace according to the needs, and then pour the raw materials into the automatic feeding system, which will send the raw materials to the feeding hopper of the medium frequency induction heating furnace and push them into the furnace head in turn Heating, the material after heating is discharged through the automatic feeding system;

[0042] 2) After the central control system detects that there is a material signal in the automatic feeding system, it starts the industrial robot A to send the material into the mechanical pressure forging machine, then returns to reset and feeds back the reset signal to the central control system, and the central control system starts the mechanical pressure forging machine. Forging blow operati...

Embodiment 3

[0046] A forging production line (ring gear forging), adopting the flexible automatic forging production line described in claim 4, the operation process is as follows:

[0047] 1) Pre-set the production cycle of the medium frequency induction heating furnace according to the needs, and then pour the raw materials into the automatic feeding system, which will send the raw materials to the feeding hopper of the medium frequency induction heating furnace and push them into the furnace head in turn Heating, the material after heating is discharged through the automatic feeding system;

[0048] 2) After the central control system detects that there is a material signal in the automatic feeding system, it starts the industrial robot A to send the material into the mechanical pressure forging machine, then returns to reset and feeds back the reset signal to the central control system, and the central control system starts the mechanical pressure forging machine. Forging blow operati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com