Method for controlling micro-medium wave rolling of hot-rolled strip steel at high precision

A hot-rolled strip steel, high-precision technology, applied in the direction of contour control, program control, computer control, etc., can solve problems such as increased bending force, increased difference between measured flatness and target flatness, and poor shape , to achieve the effect of improving the accuracy of the plate shape, reducing the production cost and improving the production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0093] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

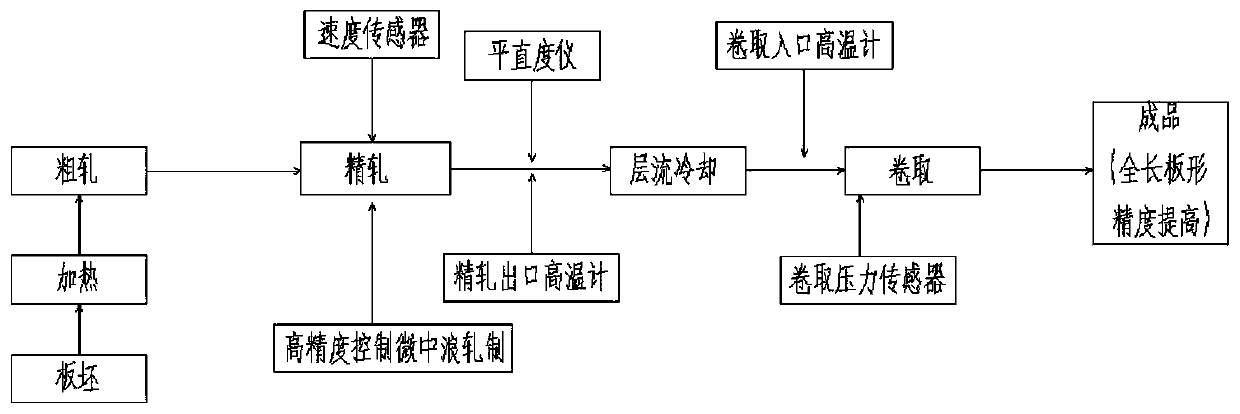

[0094] Such as figure 2 As shown, in the hot-rolled strip production line consisting of slab heating-rough rolling-finish rolling-laminar cooling-coiling-finished product, high-precision control of hot-rolled strip micro The purpose of the middle wave rolling link is to combine the real-time speed and temperature, according to the different rolling process states of the strip steel, through the whole process of adopting a high-precision control method that dynamically adjusts the target flatness value in stages in real time, to compensate for coiling. Effects of tension and cooling rate variation factors on strip micro-wave control. Therefore, the strip shape of the full length of the strip is dynamically controlled, and the strip shape accuracy of the full length of the strip is improved.

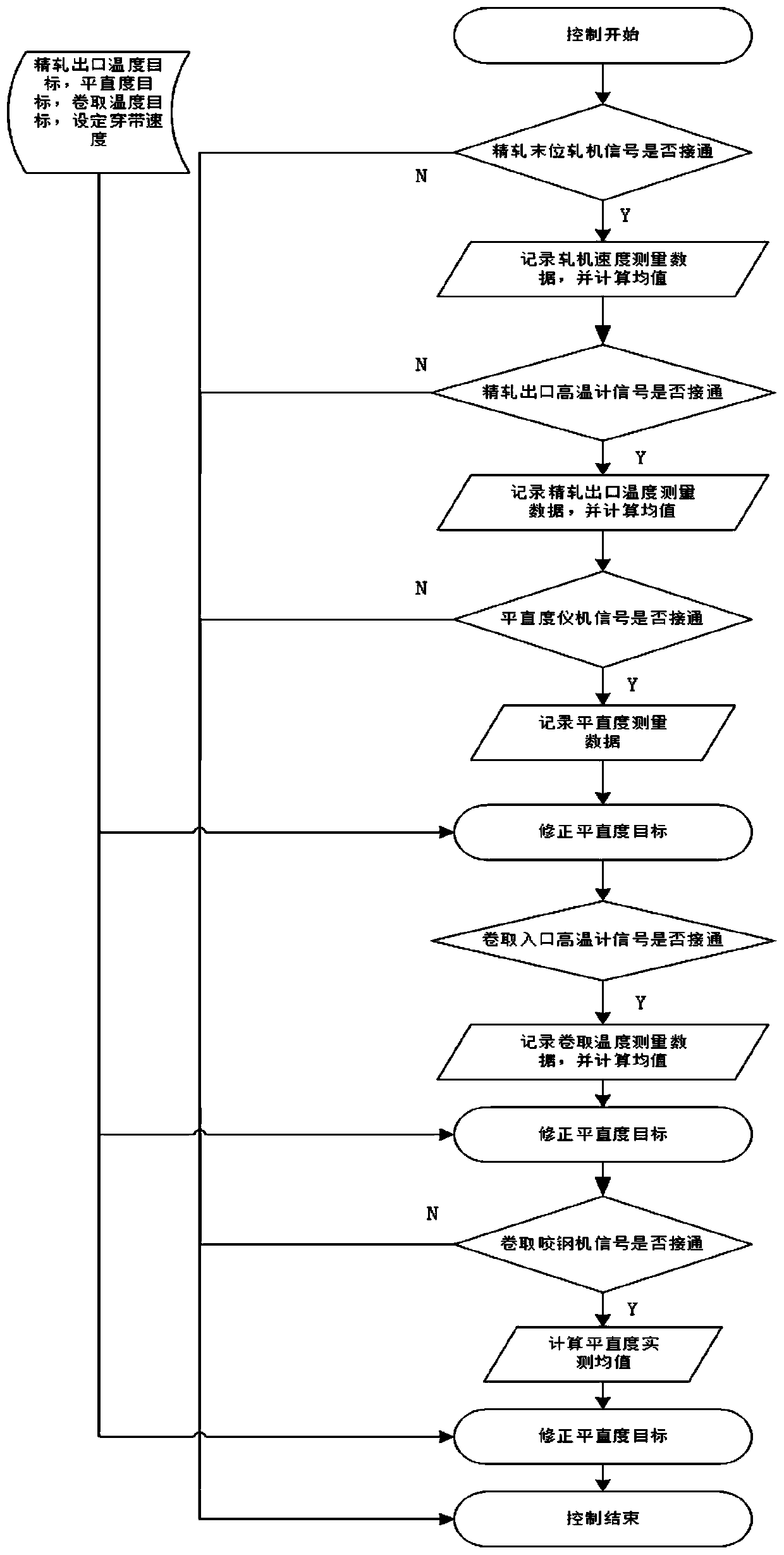

[0095] Such as image 3 As shown, the present inv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com