A method for recovering barium-strontium pyrochlore from weathered and altered carbonate-type niobium polymetallic ore

A carbonate-type, polymetallic ore technology, applied in chemical instruments and methods, wet separation, solid separation, etc., can solve the problems of unrecoverable barium strontium pyrochlore, low recovery rate, lack of sorting process, etc. , to achieve the effect of reducing the processing amount of sorting operations, high recovery rate, and solving the high cost of enrichment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

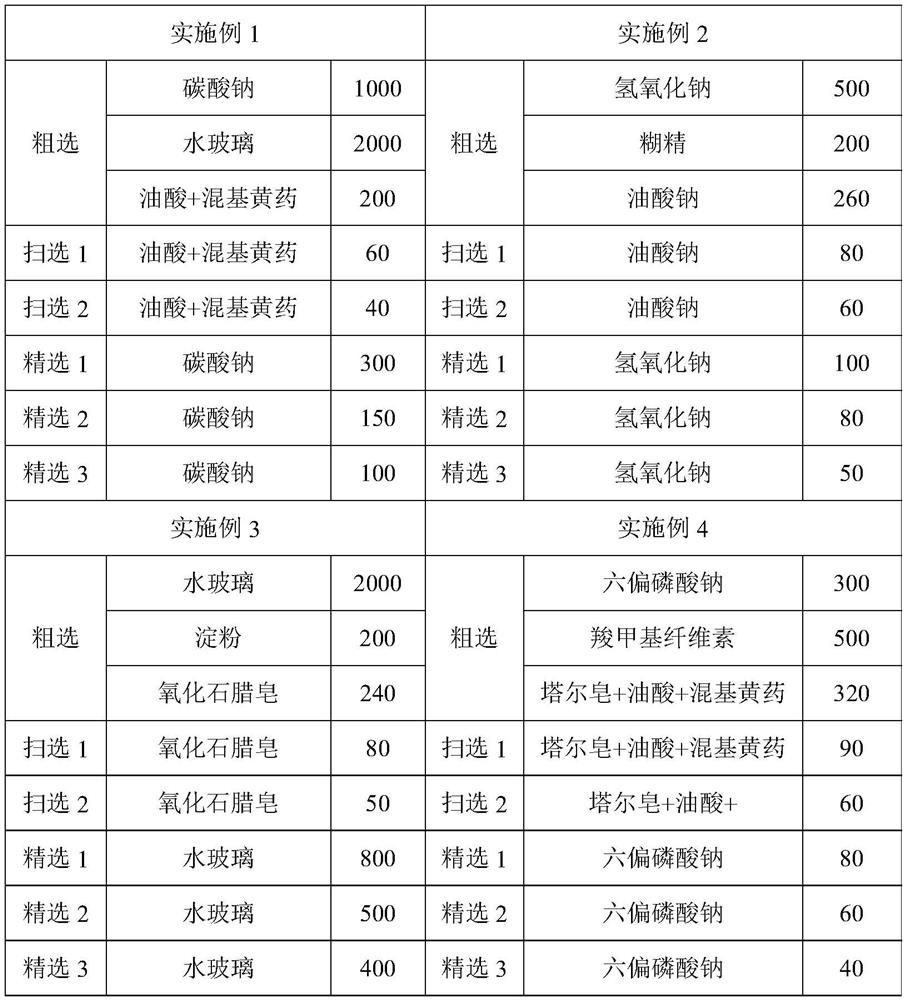

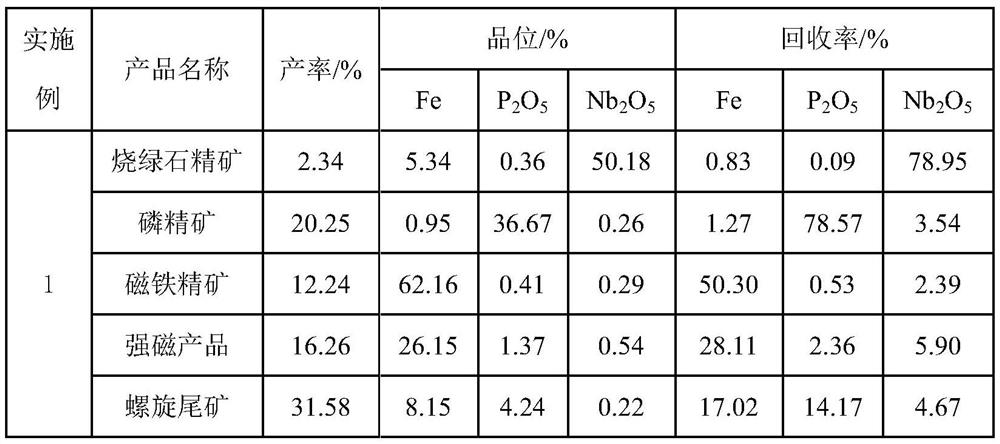

Embodiment 1

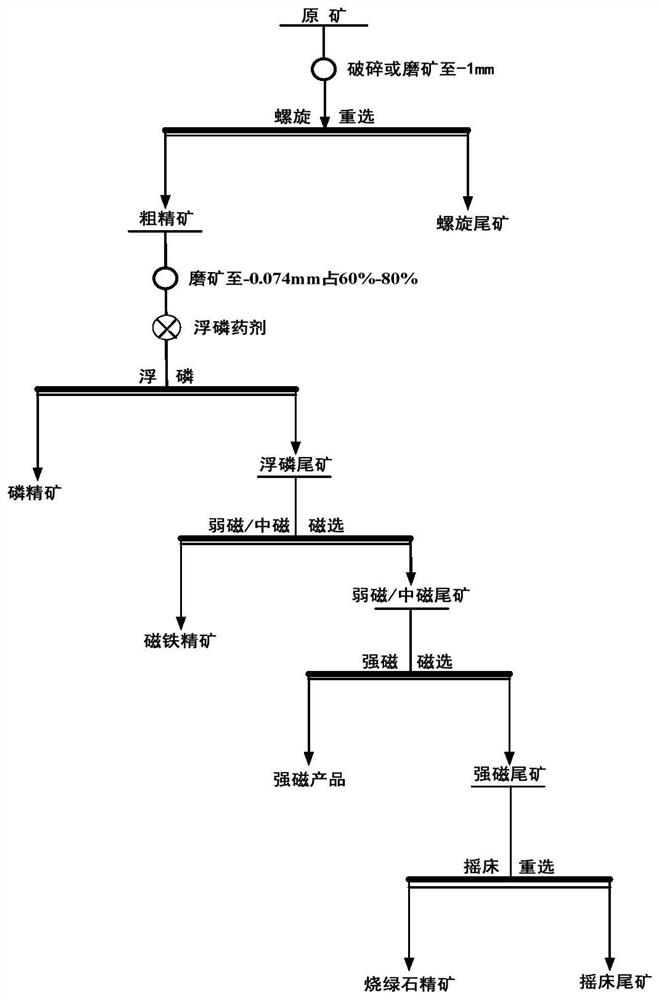

[0042] A method for recovering barium-strontium pyrochlore from weathered and altered carbonate-type niobium polymetallic ore, comprising the steps of:

[0043] S1. Raw ore grinding to -1mm accounts for 90%;

[0044] S2. Add water to the product after grinding to adjust the pulp concentration to 25%, and carry out spiral gravity separation in the spiral chute to obtain coarse concentrate and spiral tailings;

[0045] S3. Regrind the coarse concentrate to -0.074mm to account for 70%, add water to adjust the slurry to a pulp concentration of 30%, add floating phosphorus reagents, and perform apatite flotation to obtain phosphorus concentrate and floating phosphorus tailings;

[0046] S4. Feed the floating phosphorus tailings into a weak or medium magnetic separator for weak or medium magnetic separation, adjust the magnetic field strength to 0.15T, and obtain iron concentrate and weak or medium magnetic tailings;

[0047] S5. Feed the weak magnetic / medium magnetic tailings into...

Embodiment 2

[0053] A method for recovering barium-strontium pyrochlore from weathered and altered carbonate-type niobium polymetallic ore, comprising the steps of:

[0054] S1. Raw ore grinding to -1mm accounts for 85%;

[0055] S2. Add water to the product after grinding to adjust the pulp concentration to 20%, and carry out spiral gravity separation in the spiral chute to obtain coarse concentrate and spiral tailings;

[0056] S3. Regrind the coarse concentrate to -0.074mm to account for 76%, add water to adjust the slurry to a pulp concentration of 25%, add floating phosphorus reagents, and perform apatite flotation to obtain phosphorus concentrate and floating phosphorus tailings;

[0057] S4. Feed the floating phosphorus tailings into the weak magnetic separator for weak magnetic separation, adjust the magnetic field strength to 0.25T, and obtain iron concentrate and weak magnetic tailings;

[0058] S5. Feed the weak magnetic tailings into the strong magnetic separator for strong ma...

Embodiment 3

[0064] A method for recovering barium-strontium pyrochlore from weathered and altered carbonate-type niobium polymetallic ore, comprising the steps of:

[0065] S1. Raw ore grinding to -1mm accounts for 88%;

[0066] S2. Add water to the product after grinding to adjust the pulp concentration to 30%, and carry out spiral gravity separation in the spiral chute to obtain coarse concentrate and spiral tailings;

[0067] S3. Regrind the coarse concentrate to -0.074mm to account for 80%, add water to adjust the slurry to a pulp concentration of 35%, add floating phosphorus reagents, and perform apatite flotation to obtain phosphorus concentrate and floating phosphorus tailings;

[0068] S4. Feed the floating phosphorus tailings into the medium magnetic separator for weak magnetic separation, adjust the magnetic field strength to 0.35T, and obtain iron concentrate and medium magnetic tailings;

[0069] S5. Feed the medium magnetic tailings into the strong magnetic separator for str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com