Preparation method of hollow iron selenium derivative catalyst and product and application thereof

A hollow-shaped and derivative technology, which is applied in the field of preparation of hollow-shaped iron-selenium derivative catalysts, can solve problems such as price disadvantage and unsatisfactory electrocatalytic properties such as stability, and achieves low turn-on voltage, good catalytic stability, and improved catalytic performance. The effect of catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

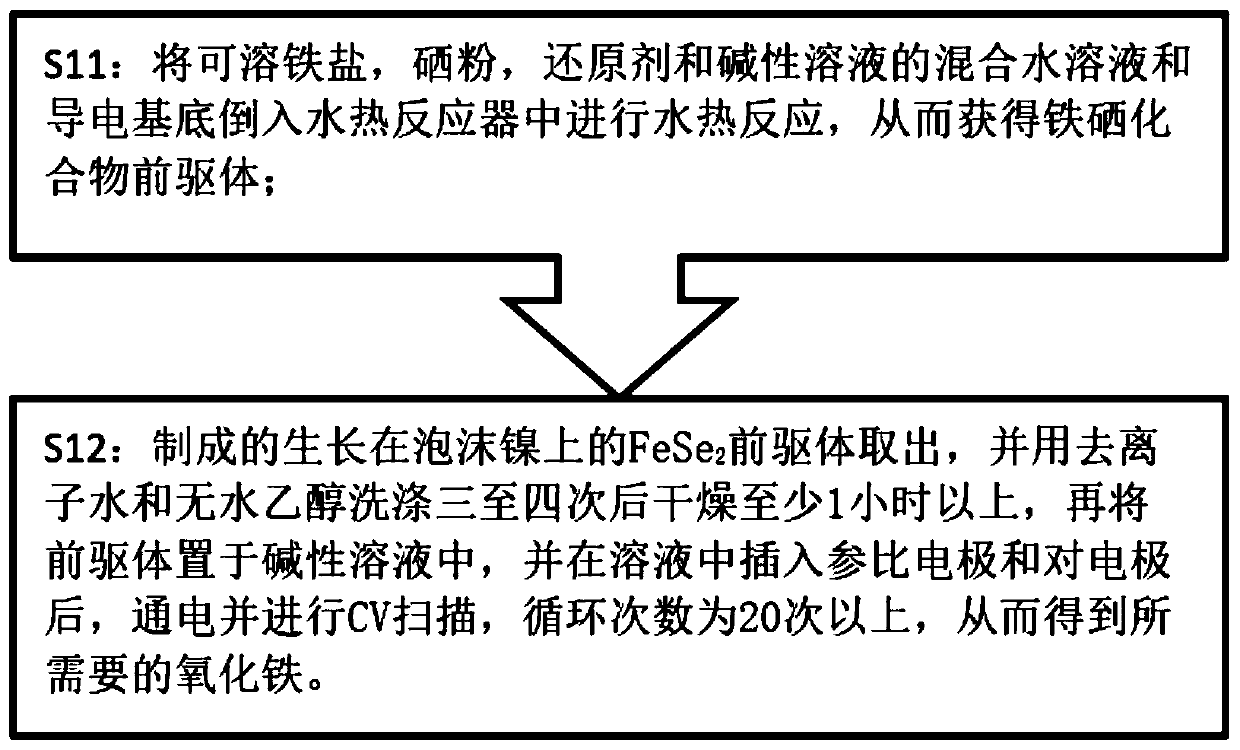

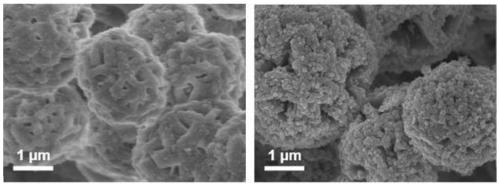

[0032]Aiming at the shortcomings of existing commercial catalysts as catalysts, the purpose of the present invention is to provide a stable oxygen evolution catalyst composed of iron oxide compounds produced by the electrochemical activation of iron-selenium compounds and its preparation method, aiming to solve the problem of existing commercial precious metal production problems. Oxygen catalysts have problems such as low catalytic activity, high price, and poor stability. Generally speaking, the preparation method adopts a one-step hydrothermal method and electrochemical activation to prepare the iron-selenide derivative. The method mainly includes the following steps: 1. The first step of hydrothermal reaction is used to prepare the iron-selenide derivative. Iron selenide precursor; 2. Electrochemical activation treatment, the precursor is activated and converted into iron oxide compound, while its microscopic shape is preserved, so that the oxide has good catalytic activity...

Embodiment 1

[0040] figure 1 Show the preparation process of the iron selenium derivative oxygen evolution catalyst that this example provides, comprise the steps:

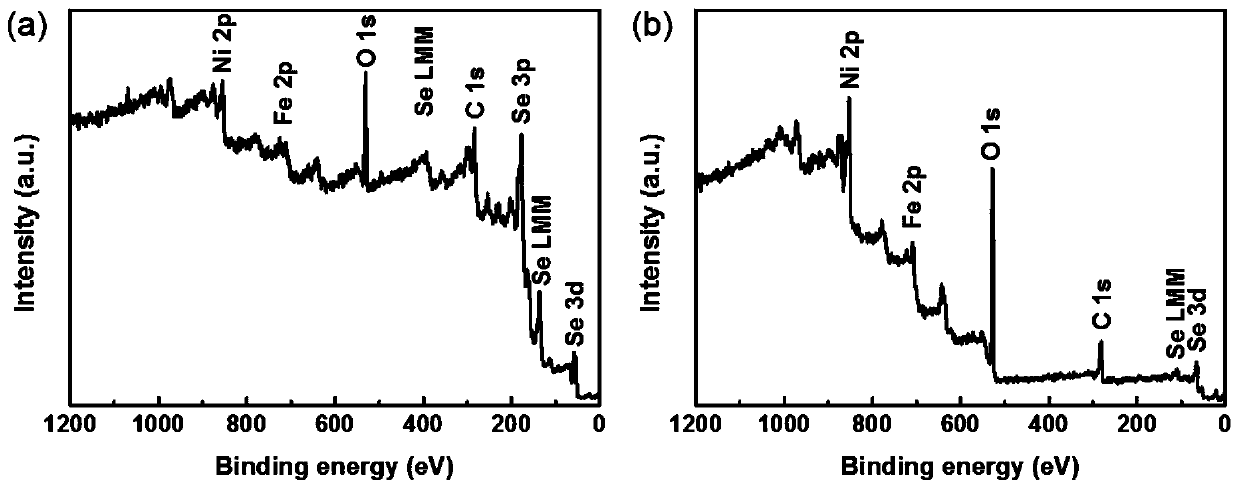

[0041] (1) Precursor preparation: Cut a piece of nickel foam with a size of 1cm×2cm, and pass through 6mol L in sequence -1 After washing with hydrochloric acid, deionized water and alcohol, put it into a 60°C oven for drying. Then, dissolve 1mmol ferrous sulfate heptahydrate and 4mmol selenium powder raw materials in 20mL deionized water, then add 3mL hydrazine hydrate and 6mL ammonia water to the mixed solution, and finally immerse the dried nickel foam in the mixed solution, and A 120° C. hydrothermal reaction was performed for 12 hours. Finally, wash and dry to obtain the precursor.

[0042] (2) Preparation of electrode and electrochemical activation of iron-selenide compound: After drying the precursor of iron-selenide compound in an oven set at 60°C for 12 hours, cut out a small piece of 1 square centimeter to obtain ...

Embodiment 2

[0045] (1) Precursor preparation: Cut a piece of nickel foam with a size of 1cm×2cm, and pass through 6mol L in sequence -1 After washing with hydrochloric acid, deionized water and alcohol, put it in a 60°C oven for drying. Next, dissolve 1mmol of ferrous nitrate and 5mmol of selenium powder raw materials in 20mL of deionized water, then add 3mL of hydrazine hydrate and 6mL of ammonia water to the mixed solution, and finally immerse the dried nickel foam in the mixed solution for 12 hours of 120°C hydrothermal reaction. Finally, wash and dry to obtain the precursor.

[0046] (2) Preparation of electrodes and electrochemical activation of iron-selenium compounds: After drying the precursors of iron-selenium compounds at 60° C. for 12 hours, cut out 1 cm2 pieces to obtain electrodes. The electrochemical performance of the catalyst is carried out in a three-electrode test cell, silver or silver chloride is used as a reference electrode, a platinum electrode is used as a counte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com