A reciprocating puncture needle tube cleaning and disinfection machine

A technology for cleaning, disinfecting and puncturing needles, applied in the directions of disinfection, cleaning hollow objects, cleaning methods and utensils, etc., can solve the problem of low cleaning efficiency, and achieve the effect of cleaning, reducing usage rate and improving cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

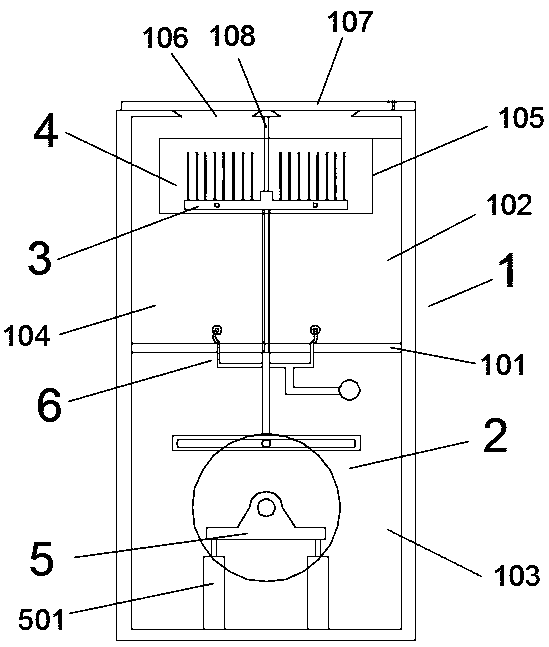

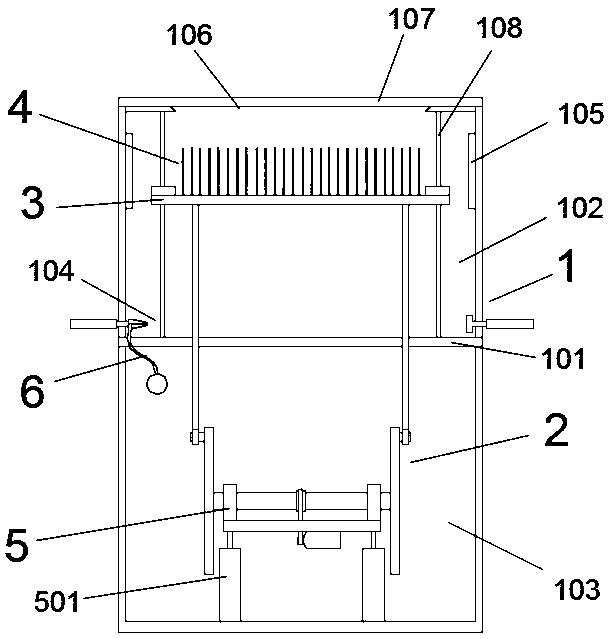

[0038] Such as Figure 1-3 As shown, a reciprocating puncture needle needle tube cleaning and disinfection machine includes a closed body 1 with a hollow chamber, and a needle tube inlet and outlet 106 and a cover plate 107 for closing the needle tube inlet and outlet 106 are opened on the top of the airtight body 1 , and the airtight body 1 There is a horizontal partition 101 inside, and the horizontal partition 101 divides the hollow chamber in the airtight body 1 into an upper working area 102 and a lower auxiliary area 103, wherein the upper working area 102 is divided into a lower alcohol cleaning area 104 and an upper The ultraviolet radiation area 105 of the upper work area 102 is provided with a pipeline for injecting and discharging alcohol into it on the side wall of the upper work area 102, and a fixed slide bar 108 is arranged vertically in the upper work area 102, and the fixed slide bar 108 is slidably provided with a lifting base plate 3, and the upper surface o...

Embodiment 2

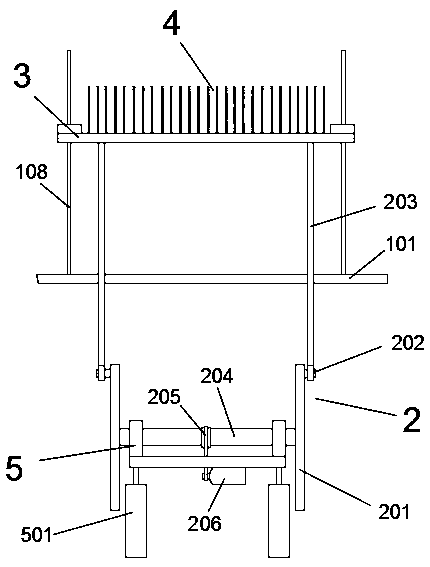

[0052] This embodiment is a limited structure made on the basis of embodiment 1, and its main structure is the same as that of embodiment 1, and the improvements are as follows: image 3 As shown, the slider crank mechanism 2 includes a rotating shaft 204 which is arranged on the fixed base plate 5 through the rotation of the bearing seat, and a driven wheel 205 is arranged on the rotating shaft 204, and the drive motor 206 provided on the lower surface of the fixed base plate 5 is driven by a belt from The driving wheel 205 and the rotating shaft 204 rotate synchronously, and the two ends of the rotating shaft 204 are symmetrically provided with a turntable 201, and the corresponding positions on the outer surfaces of the two turntables 201 away from the rotating shaft 204 are provided with push pins, and each push pin slides on a horizontal bar. In the horizontal strip groove on the shaped plate 202, a connecting rod 203 is vertically arranged in the middle of the horizontal ...

Embodiment 3

[0054] This embodiment is an improved structure made on the basis of embodiment 1, and its main structure is the same as that of embodiment 1, and the improvements are as follows: Figure 4-8 As shown, each set of support assemblies 4 includes a support needle body 401 vertically arranged on the lifting base plate 3, the top of the support needle body 401 penetrates into the needle tube to fix it, and the inner wall of the needle tube and the support needle body 401 There is a gap between the outer walls. The supporting needle body 401 has a hollow lumen 402 inside, and its surface is densely covered with micropores 404 communicating with the hollow lumen 402. The micropores 404 refer to small holes with a small diameter. Generally at 0.5-1.5mm, the bottom of the hollow lumen 402 communicates with the air blowing pipeline 303 provided in the lifting base plate 3. The air blowing line 303 has an opening on the side of the lifting base plate 3 close to the fixed slide bar 108. C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com