Medium voltage DC vacuum circuit breaker main circuit topology and breaking method thereof

A technology for vacuum circuit breakers and main circuits, applied in emergency protection circuit devices, electrical components, etc., can solve the problems of small equivalent impedance of circuit breakers, high volt-second product performance, difficult to achieve magnetic characteristics, etc., and improve the breaking reliability. , the effect of reducing the volume and cost, and facilitating the structural arrangement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

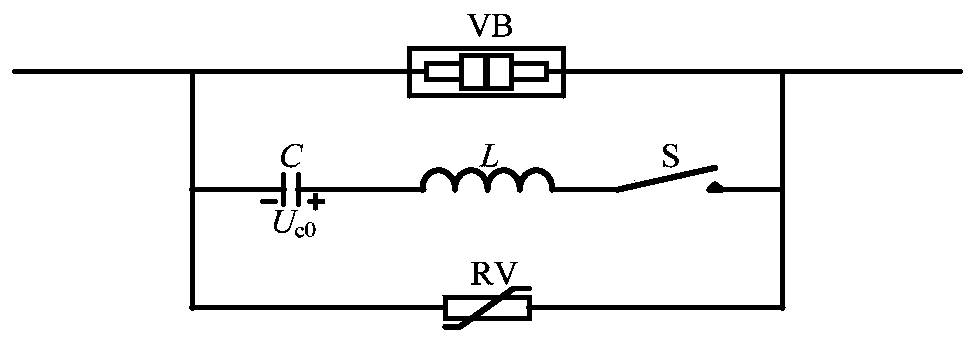

[0036] refer to Figure 7 As shown, the present invention discloses a main circuit topology of a medium voltage DC vacuum circuit breaker, including a vacuum circuit breaker VB 1 and vacuum circuit breaker VB 2 The main current path is composed of the commutation capacitor C, the auxiliary switch S and the commutation inductance L, and the commutation breaking circuit is composed of the auxiliary inductance L a and auxiliary capacitor C a Auxiliary breaking circuit composed of and energy absorbing circuit composed of piezoresistor RV.

[0037] The commutation capacitor C, the auxiliary switch S and the commutation inductance L are connected in series in sequence, and the commutation capacitor C is pre-charged U c0 , the main current path, the commutation breaking circuit and the energy absorbing circuit are connected in parallel, and the auxiliary breaking circuit is connected with the vacuum circuit breaker VB 1 connected in parallel with each other, the vacuum circuit br...

Embodiment 2

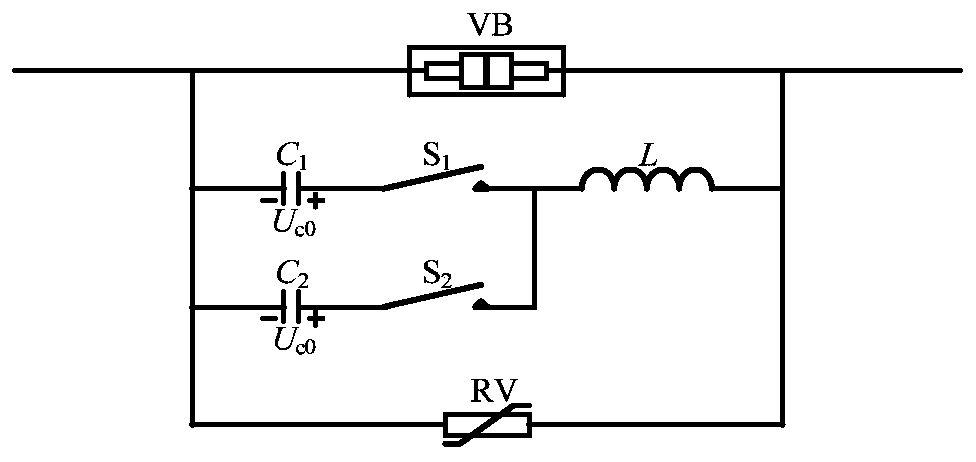

[0040] refer to Figure 8 As shown, in the normal working stage of the DC system, the vacuum circuit breaker VB 1 and vacuum circuit breaker VB 2 Closed, conducts load current. If it is necessary to break the normal load current, the breaking process is as follows:

[0041] 1) Vacuum circuit breaker VB 1 First break the arc;

[0042] 2) Then turn on the auxiliary switch S in the commutation breaking circuit, so that the commutation capacitor C passes through the auxiliary switch S, commutation inductance L, VB 2 and VB 1 The loop discharge formed by the arc gap, the generated pulse discharge current forces VB 1 The current quickly crosses zero and extinguishes the arc;

[0043] 3) Thereafter, the auxiliary inductance L a , Auxiliary capacitor C a with VB 2 Work in series and form a new second-order discharge circuit with the commutation breaking circuit, where the capacitance is equivalent to C a In series with C, the inductance is equivalent to L a and L in series...

Embodiment 3

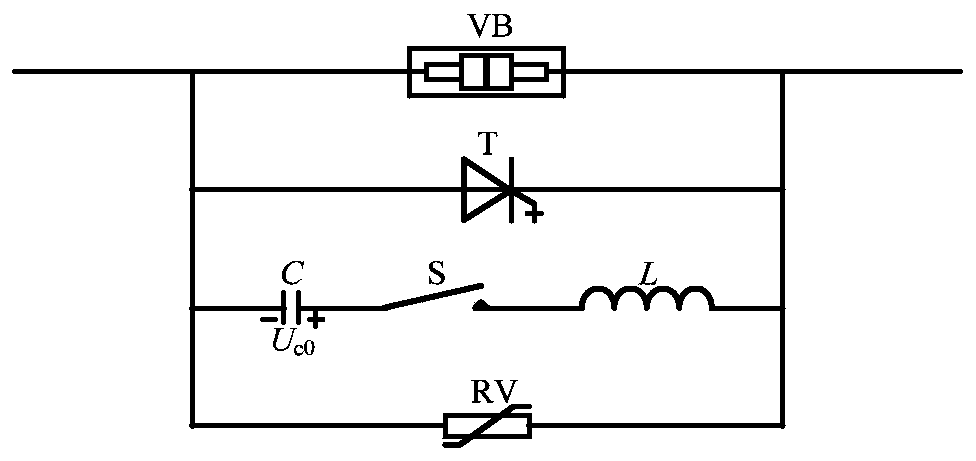

[0049] refer to Figure 9 As shown, after a short-circuit fault occurs in the DC system, the breaking process is as follows:

[0050] 1) First, the vacuum breaker VB 1 and vacuum circuit breaker VB 2 Simultaneously breaking and generating arc;

[0051] 2) Then, turn on the auxiliary switch S in the commutation breaking circuit, so that the commutation capacitor C passes through the auxiliary switch S, commutation inductance L and VB 1 , VB 2 The loop discharge formed by the arc gap, the generated pulse discharge current forces VB 1 -VB 2 The series branch current crosses zero at the same time and extinguishes the arc;

[0052] 3) If VB 1 and VB 2 Reliable arc extinguishing or only VB 2 If the arc is extinguished reliably, there is no current path in the auxiliary breaking circuit, which will not have any impact on the subsequent breaking process. Then the commutation breaking circuit is connected to the DC system to work, and C is reversely charged under the action of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com