Mortar anti reload device

A mortar and anti-heavy technology, which is applied in the field of mortar anti-heavy equipment, can solve the problems of psychological will damage, impact on launch, secondary reloading, etc., and achieve improved safety, convenient use, and high reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

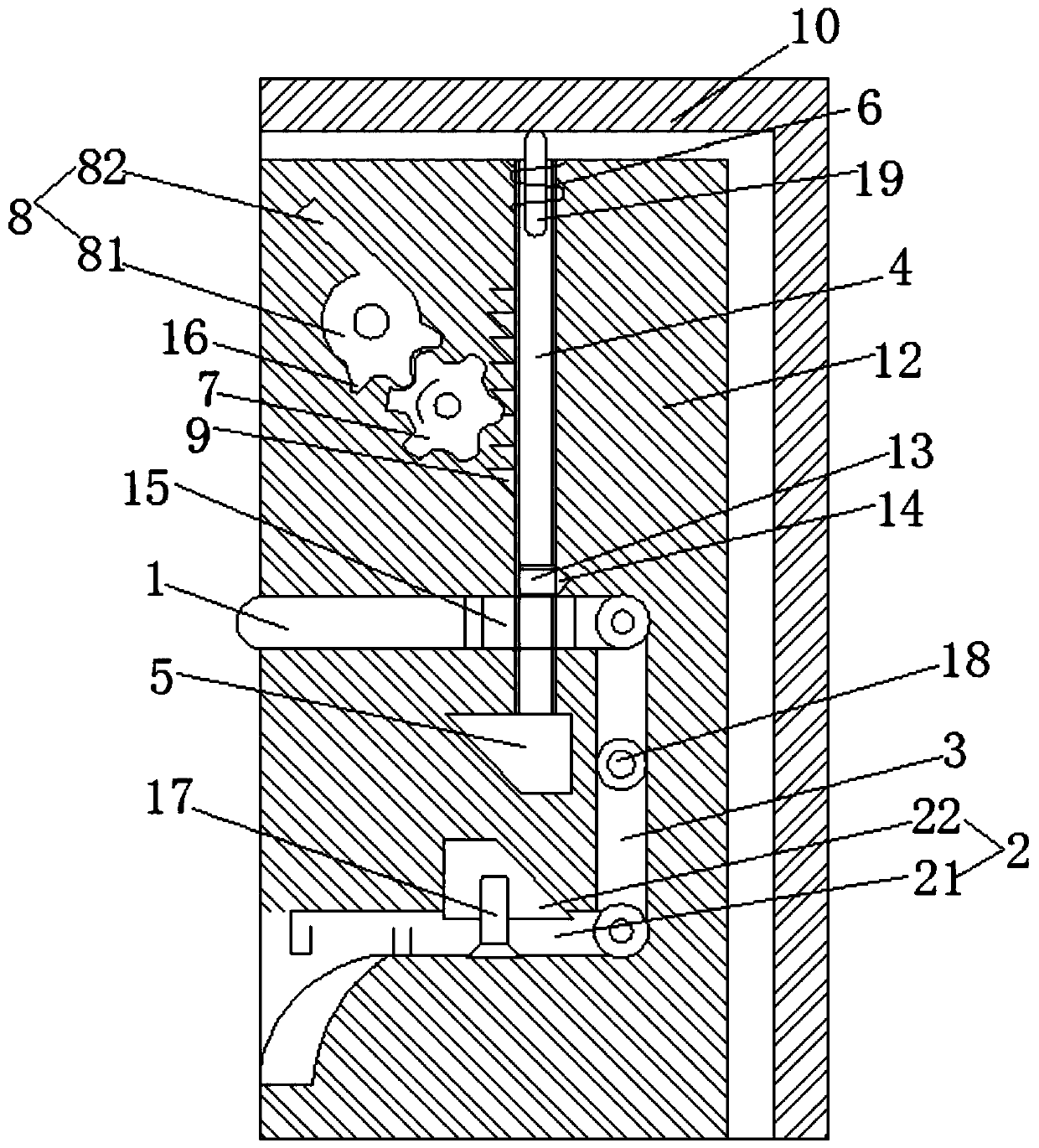

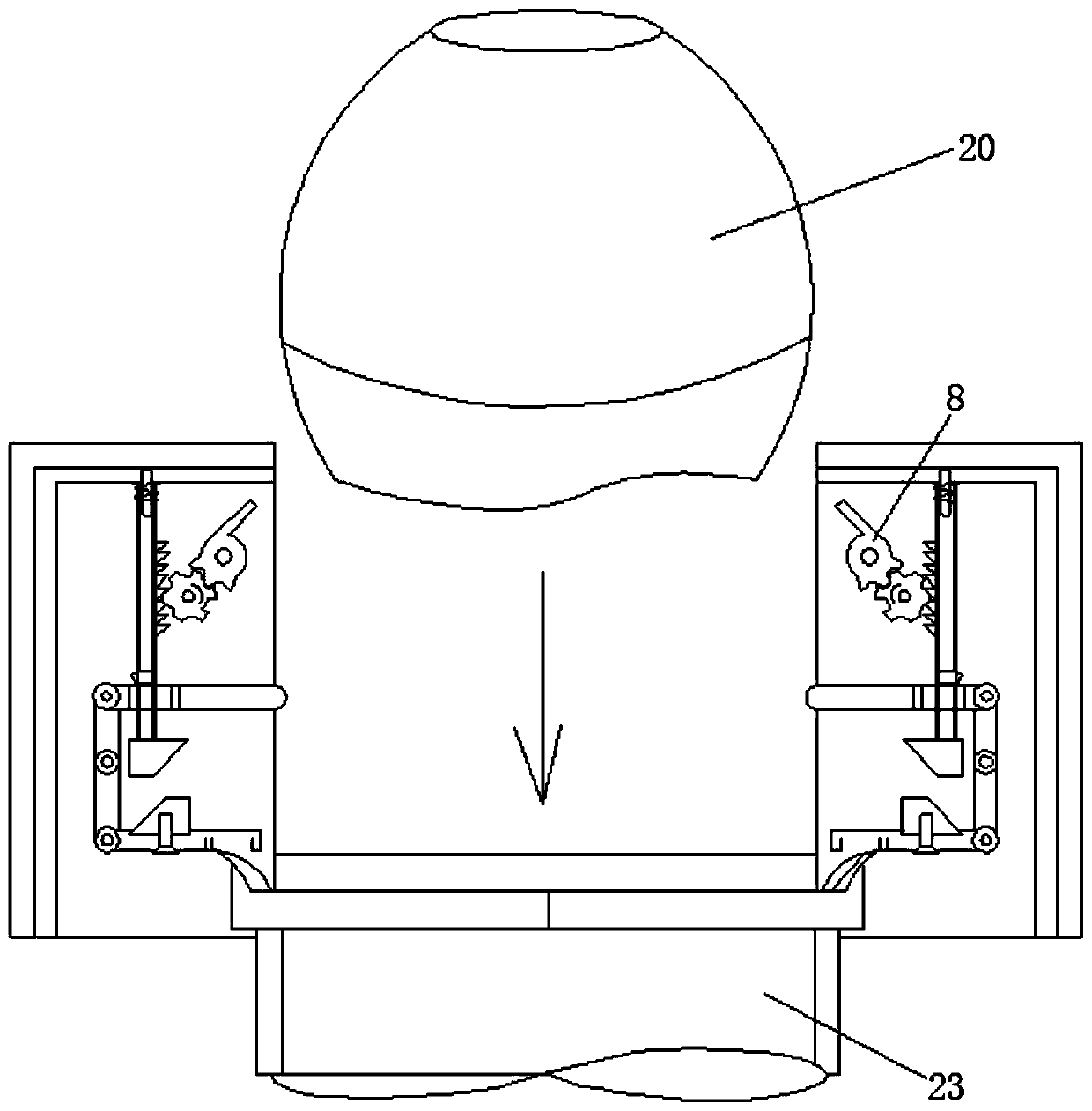

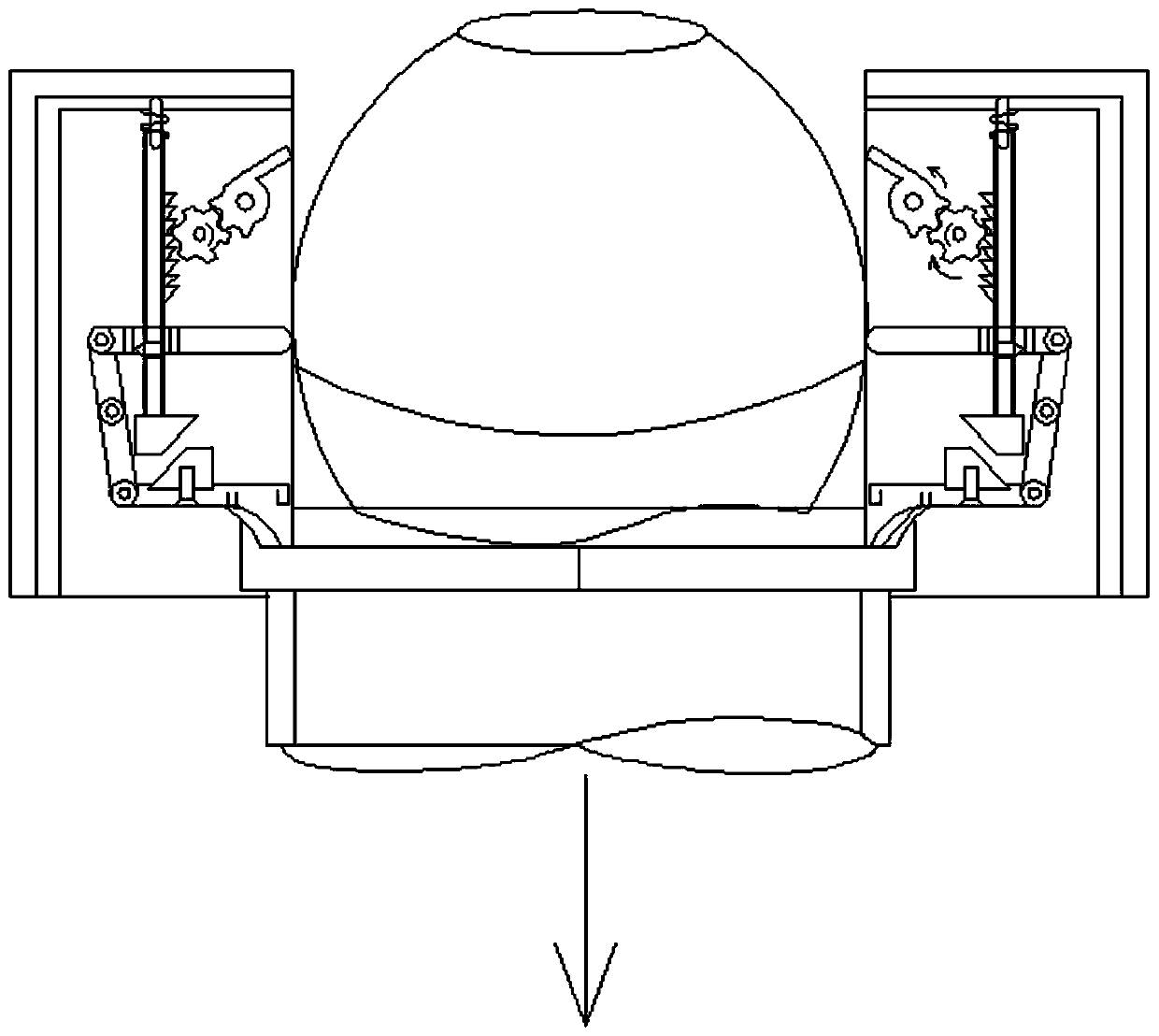

[0023] Such as figure 1 The mortar anti-reloading device shown includes a main body; the main body is tightly hooped to the mortar muzzle by a base; the main body is composed of two anti-reloading mechanisms installed symmetrically on the outside of the mortar bore; the The anti-reinstallation mechanism includes a body 12, a body assembly installed on the body 12, a connection system and a bullet-stopping assembly; the top of the body 12 is covered with a cover plate 10; the body assembly is connected to the bullet-stopping assembly through a connection system;

[0024] The body assembly includes a first slider 1, a second slider 2 and a rocker 3; the first slider 1 is connected to the second slider 2 through the rocker 3; the first slider 1 and the second The sliders 2 are respectively movably installed in the first chute and the second chute opened on both sides of the body 12, and the first slider 1 is located above the second slider 2;

[0025] The connecting system inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com