Composite steel U-shaped anti-seismic steel frame and construction method thereof

A composite steel and composite steel pipe technology, which is applied in earthquake resistance, building components, building types, etc., can solve the problems of consuming large fresh water resources, increasing structural construction costs, and high maintenance costs, and achieves good durability, reasonable design, and high wind load. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

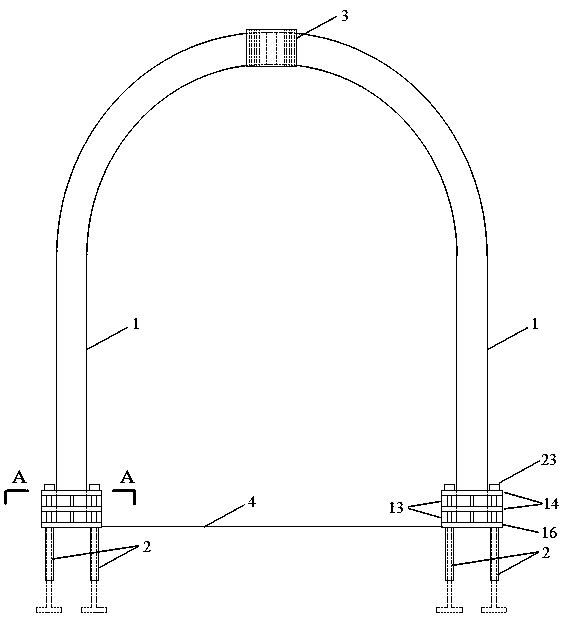

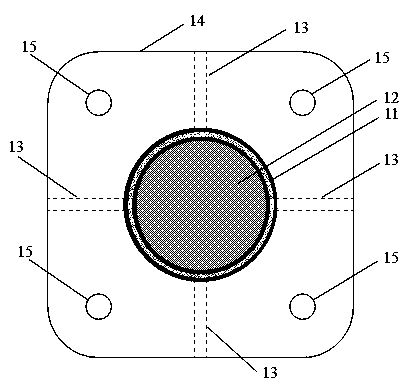

[0027] like Figure 1-4 As shown, a composite steel U-shaped seismic steel frame includes a U-shaped composite steel pipe frame. The thickness of the pipe wall is greater than that of the stainless steel inner layer and the stainless steel outer layer, the composite steel pipe frame is filled with sea sand concrete, and column feet are installed at both ends of the composite steel pipe frame.

[0028] In this embodiment, the composite steel pipe frame includes two pipe frame units symmetrically arranged left and right. The alloy sleeves are connected, and the shape memory effect of the memory alloy is used. The shape memory alloy sleeve can conveniently and reliably connect the two prefabricated pipe frame units together, and it can also be easily disassembled when the composite steel pipe frame is damaged.

[0029] In this embodiment, the me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com