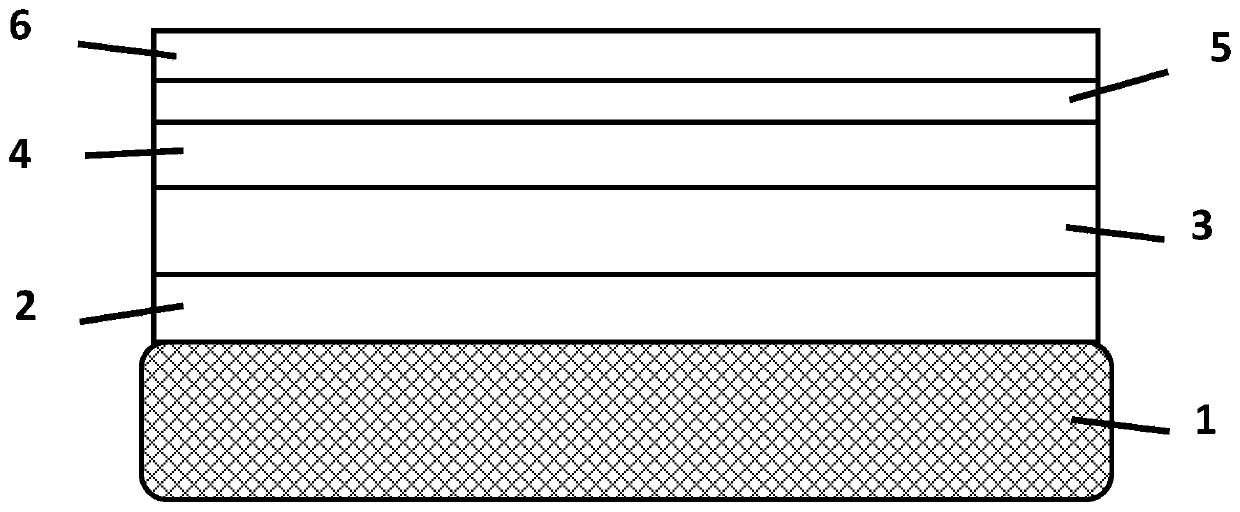

Color fiber fabric and production method thereof

A production method and fiber technology, which are applied in the field of colored fiber fabrics and their production, can solve the problems of poor oxidation resistance and wear resistance of the film layer, decreased film fastness, single color, etc., so as to improve the anti-oxidation and corrosion resistance, The effect of avoiding oxidation problems and simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] Taking the deposition of a composite film layer on the surface of pongee base fabric by magnetron sputtering winding coating technology as an example, the specific production steps are as follows:

[0071] 1. Prepare the pongee required for production and wash and dry it to remove surface stains and water.

[0072] 2. Connect the pre-treated pongee to the unwinding device and keep the fabric flat on its surface, then the sealed chamber starts to pump air, and when the vacuum degree rises to 5.0E-3Pa, the required for this production All targets are sputtered to clean the target surface.

[0073] 3. The base fabric will pass through the heating room before entering the process room. For pongee, a synthetic fiber with low moisture content, it can also pass through directly without heating and drying.

[0074] 4. The pongee base fabric is transported into the process room at a production speed of 1m / min to start depositing the buffer layer. The buffer layer is Ti, the nu...

Embodiment 2

[0079] Taking the deposition of a composite film layer on the surface of pongee base fabric by magnetron sputtering winding coating technology as an example, the specific production steps are as follows:

[0080] 1. Prepare the pongee required for production and wash and dry it to remove surface stains and moisture.

[0081] 2. Connect the pre-treated pongee to the unwinding device and keep the fabric flat on its surface, then the sealed chamber starts to pump air, and when the vacuum degree rises to 5.0E-3Pa, the required for this production All targets are sputtered to clean the target surface.

[0082] 3. The base fabric will pass through the heating room before entering the process room. For pongee, a synthetic fiber with low moisture content, it can also pass through directly without heating and drying.

[0083] 4. The pongee base fabric is transported into the process room at a production speed of 1m / min to start depositing the buffer layer. The buffer layer is TiN, us...

Embodiment 3

[0088] Taking the application of magnetron sputtering winding coating technology to coat the composite film layer on the surface of the simulated silk base fabric as an example, the specific production steps are as follows:

[0089] 1. Prepare the white imitation silk required for production and wash and dry it to remove surface stains and moisture.

[0090] 2. Connect the pre-treated imitation silk to the unwinding device and keep the fabric flat on its surface, then the sealed chamber starts to pump air, and when the vacuum degree rises to 5.0E-3Pa, all the materials required for this production The target is sputtered to clean the target surface.

[0091] 3. The base fabric will pass through the heating room before entering the process room. For synthetic fibers with low moisture content such as silk, there is no need for secondary heating and drying.

[0092] 4. The imitation silk base fabric is transported into the process room at a production speed of 1m / min to start de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com