Soil conditioner for controlling soil phosphorus loss and its preparation method and application

The technology of soil conditioner and soil phosphorus is applied in the field of soil conditioner for controlling soil phosphorus loss and its preparation, so as to achieve the effects of improving water status, improving soil structure and enriching active sites.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

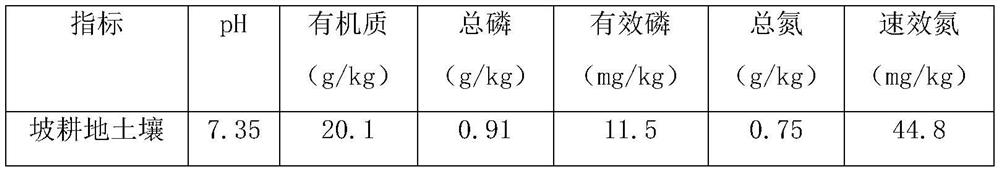

Method used

Image

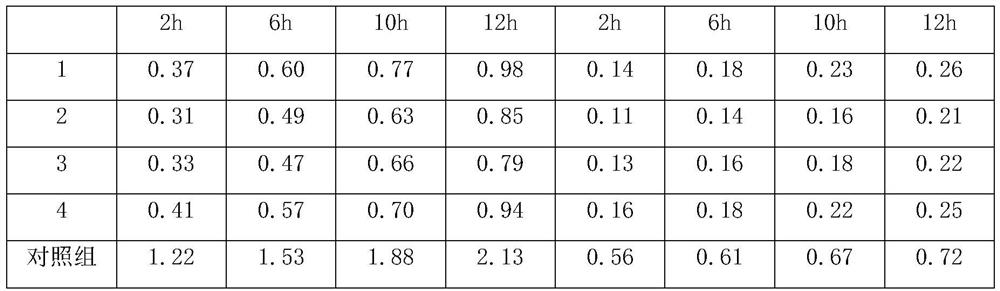

Examples

Embodiment 1

[0027] The soil conditioner of this embodiment includes the following raw materials in parts by weight: 80 parts of porous carbon base, 25 parts of ferrous sulfate, 5 parts of aluminum sulfate, 10 parts of polyacrylamide, and 45 parts of modified loofah.

[0028] The porous carbon-based preparation method is as follows:

[0029]Crush peanut shells through a 200-mesh sieve, soak the obtained powder in a phosphoric acid solution with a temperature of 80°C and a mass concentration of 75% for 40 hours, filter, and calcinate for 3 hours at a temperature of 700-760°C, take it out and place it in a normal temperature Soak in a hydrochloric acid solution with a hydrogen chloride mass concentration of 18% for 24 hours, filter, deionize and wash to pH=6.5-7.5, then add a 20w% sodium bicarbonate solution, and then carbonize in a nitrogen environment at 500-550°C 4h, cooled, taken out, and crushed to obtain a porous carbon base.

[0030] The preparation method of modified loofah is as fo...

Embodiment 2

[0038] The soil conditioner of this embodiment includes the following raw materials in parts by weight: 85 parts of porous carbon base, 30 parts of ferrous sulfate, 0 parts of aluminum sulfate, 10 parts of polyacrylamide, and 50 parts of modified loofah.

[0039] The porous carbon-based preparation method is as follows:

[0040] Crush peanut shells through a 200-mesh sieve, soak the obtained powder in a phosphoric acid solution with a temperature of 80°C and a mass concentration of 75% for 45 hours, filter, and calcinate for 3 hours at a temperature of 650-700°C, take it out and place it in a normal temperature Soak in hydrochloric acid solution with a hydrogen chloride mass concentration of 18% for 24 hours, filter, deionize and wash to pH=6.5-7.5, then add potassium bicarbonate solution with a concentration of 20w%, and then carbonize in a nitrogen environment at 500-550°C 4h, cooled, taken out, and crushed to obtain a porous carbon base.

[0041] The preparation method of ...

Embodiment 3

[0049] The soil conditioner of this embodiment includes the following raw materials in parts by weight: 90 parts of porous carbon base, 35 parts of ferrous sulfate, 10 parts of aluminum sulfate, 15 parts of polyacrylamide, and 50 parts of modified loofah.

[0050] The porous carbon-based preparation method is as follows:

[0051] Crush peanut shells through a 200-mesh sieve, soak the obtained powder in a phosphoric acid solution with a temperature of 80°C and a mass concentration of 75% for 45 hours, filter, and calcinate for 3 hours at a temperature of 710-760°C, take it out and place it in a normal temperature Soak in hydrochloric acid solution with a hydrogen chloride mass concentration of 18% for 24 hours, filter, deionize and wash to pH = 6.5-7.5, then add calcium bicarbonate solution with a concentration of 20w%, and then place it in a nitrogen environment at 500-550°C for carbonization 4h, cooled, taken out, and crushed to obtain a porous carbon base.

[0052] The prep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com