Titanium dioxide nano-porous coating and preparation method thereof

A nano-porous, titanium oxide technology, applied in coatings and other directions, can solve problems such as film cracking, achieve the effects of reducing the possibility of cracking, alleviating easy cracking, and uniform particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

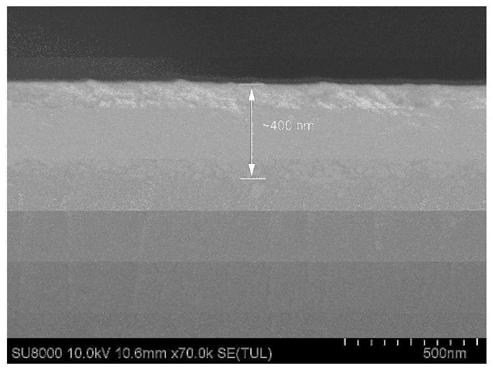

Image

Examples

Embodiment 1

[0042] The concrete steps of preparation are:

[0043] Step 1: Firstly, according to the volume ratio of tetrabutyl titanate, ethanol, isopropanol and acetic acid as 1:1.8:1.2:0.3, the latter three are mixed and stirred, and tetrabutyl titanate is added thereto to obtain mixture. Then, according to the volume ratio of water, 65% nitric acid aqueous solution, ethanol and isopropanol in a volume ratio of 0.2:0.014:1.8:1.2, the four are mixed and stirred to obtain an acidic mixed aqueous solution.

[0044] Step 2: First, according to the volume ratio of the mixed solution and ethanol in the acidic mixed aqueous solution of 1:1, the mixed solution is dropped into the acidic mixed aqueous solution drop by drop to obtain a reaction precursor solution. Then the reaction precursor solution was placed at 55°C and stirred at a rate of 600r / min for 2.5h to obtain TiO 2 Sol.

[0045] Step 3, wait for TiO 2 After the sol was allowed to cool to room temperature, 4 wt % polyvinylpyrrolid...

Embodiment 2

[0048] The concrete steps of preparation are:

[0049]Step 1: Firstly, according to the volume ratio of tetrabutyl titanate, ethanol, isopropanol and acetic acid as 1:1.9:1.1:0.35, the latter three are mixed and stirred, and tetrabutyl titanate is added thereto to obtain mixture. Then, according to the volume ratio of water, 66% nitric acid aqueous solution, ethanol and isopropanol in a volume ratio of 0.2:0.014:1.9:1.1, the four are mixed and stirred to obtain an acidic mixed aqueous solution.

[0050] Step 2: First, according to the volume ratio of the mixed solution and ethanol in the acidic mixed aqueous solution of 1:1, the mixed solution is dropped into the acidic mixed aqueous solution drop by drop to obtain a reaction precursor solution. Then the reaction precursor solution was placed at 58°C and stirred at a rate of 600r / min for 2.3h to obtain TiO 2 Sol.

[0051] Step 3, wait for TiO 2 After the sol was allowed to cool to room temperature, 4.5 wt % polyvinylpyrrol...

Embodiment 3

[0054] The concrete steps of preparation are:

[0055] Step 1. First, according to the volume ratio of tetrabutyl titanate, ethanol, isopropanol and acetic acid as 1:2:1:0.4, the latter three are mixed and stirred, and tetrabutyl titanate is added thereto to obtain mixture. Then, according to the volume ratio of water, 66.5% nitric acid aqueous solution, ethanol and isopropanol in a volume ratio of 0.2:0.014:2:1, the four are mixed and stirred to obtain an acidic mixed aqueous solution.

[0056] Step 2: First, according to the volume ratio of the mixed solution and ethanol in the acidic mixed aqueous solution of 1:1, the mixed solution is dropped into the acidic mixed aqueous solution drop by drop to obtain a reaction precursor solution. Then the reaction precursor solution was placed at 60°C and stirred at a rate of 600r / min for 2h to obtain TiO 2 Sol.

[0057] Step 3, wait for TiO 2 After the sol was allowed to cool to room temperature, 5 wt % polyvinylpyrrolidone was ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com