Method for preparing HPAA compounded pH response type bentonite

A technology of bentonite and activated bentonite is applied in the field of preparation of pH-responsive bentonite, which can solve the problem that bentonite cannot meet site requirements, and achieve the effects of enhancing flexibility, preventing shale formation damage, and ensuring plugging strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The present embodiment provides a kind of preparation method of HPAA composite pH-responsive bentonite, the main reaction process, comprising the following steps:

[0028] (1) 3 g of bentonite was prepared into 100 mL of bentonite slurry with a mass percentage of 3%, and stirred at a constant temperature of 45° C. for 12 hours to fully hydrate the bentonite;

[0029] (2) Add 1.5g of citric acid dihydrate crystals, stir at a constant temperature of 55°C for 3h, and the stirring speed is 120r·min -1 ; Add 2.1g of silane coupling agent KH570 and stir for 11 hours at an ultrasonic frequency of 100KHz and a temperature of 65-70°C;

[0030] (3) After the reaction, the resulting activated bentonite slurry was centrifuged and washed to neutrality, then placed in a constant temperature drying oven at 80°C for 24 hours, and then pulverized to 500-800nm with a nano pulverizer to obtain activated bentonite;

[0031] (4) Take 2g of activated bentonite, add distilled water, and st...

Embodiment 2

[0034] This embodiment provides a kind of preparation method of HPAA composite pH response type bentonite, the main reaction process is as follows figure 1 shown, including the following steps:

[0035] (1) 3 g of bentonite was prepared into 100 mL of bentonite slurry with a mass percentage of 3%, and stirred at a constant temperature of 45° C. for 12 hours to fully hydrate the bentonite;

[0036] (2) Add 10g of citric acid dihydrate crystals, stir at a constant temperature of 55°C for 3h, and the stirring speed is 120r·min -1 ; Then add 5g of silane coupling agent KH570 and stir for 11 hours at an ultrasonic frequency of 60KHz and a temperature of 65-70°C;

[0037] (3) After the reaction, the resulting activated bentonite slurry was centrifuged and washed to neutrality, then placed in a constant temperature drying oven at 80°C for 24 hours, and then pulverized to 500-800nm with a nano pulverizer to obtain activated bentonite;

[0038] (4) Take 2g of activated bentonite, a...

Embodiment 3

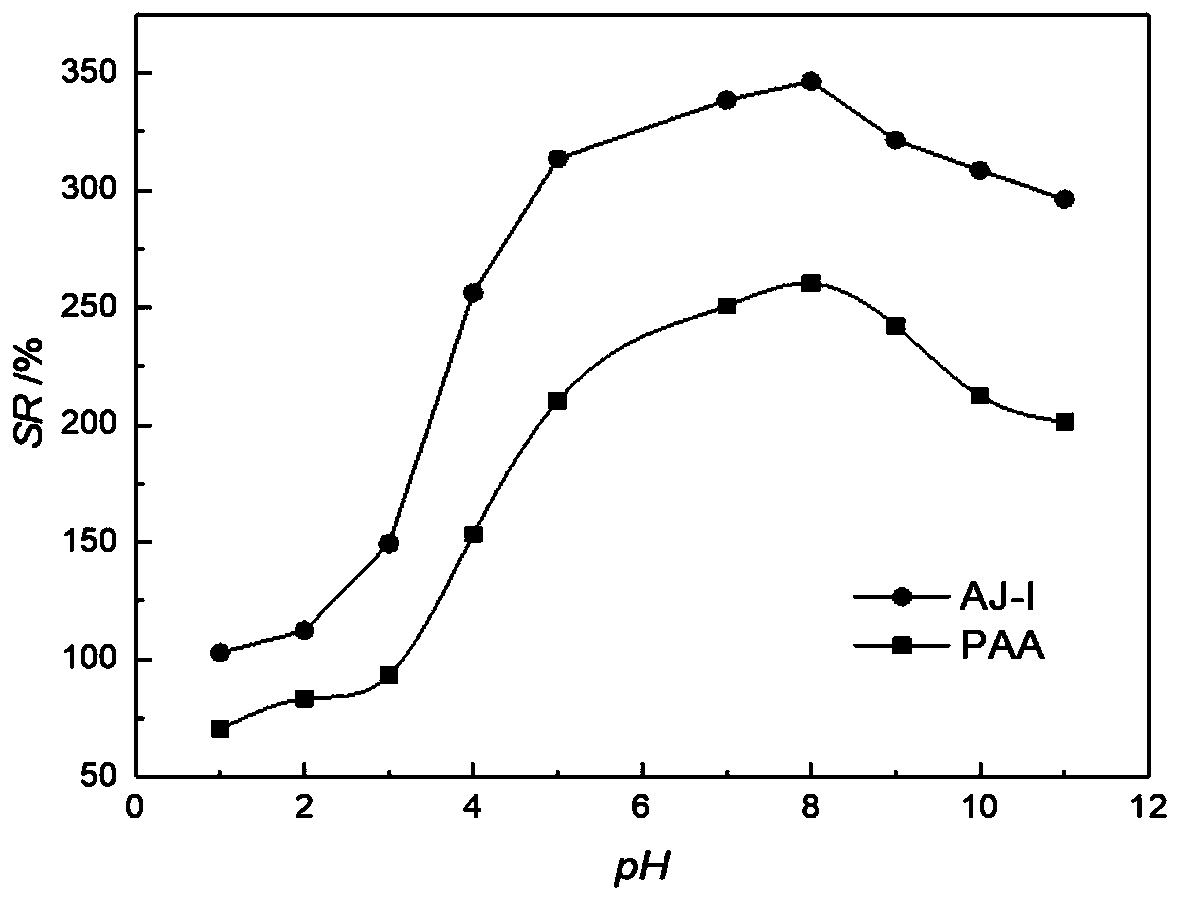

[0041] The swelling degree of the pH response type bentonite prepared by Test Example 2, the concrete process is as follows: (hereinafter referred to as pH response type bentonite is AJ-1)

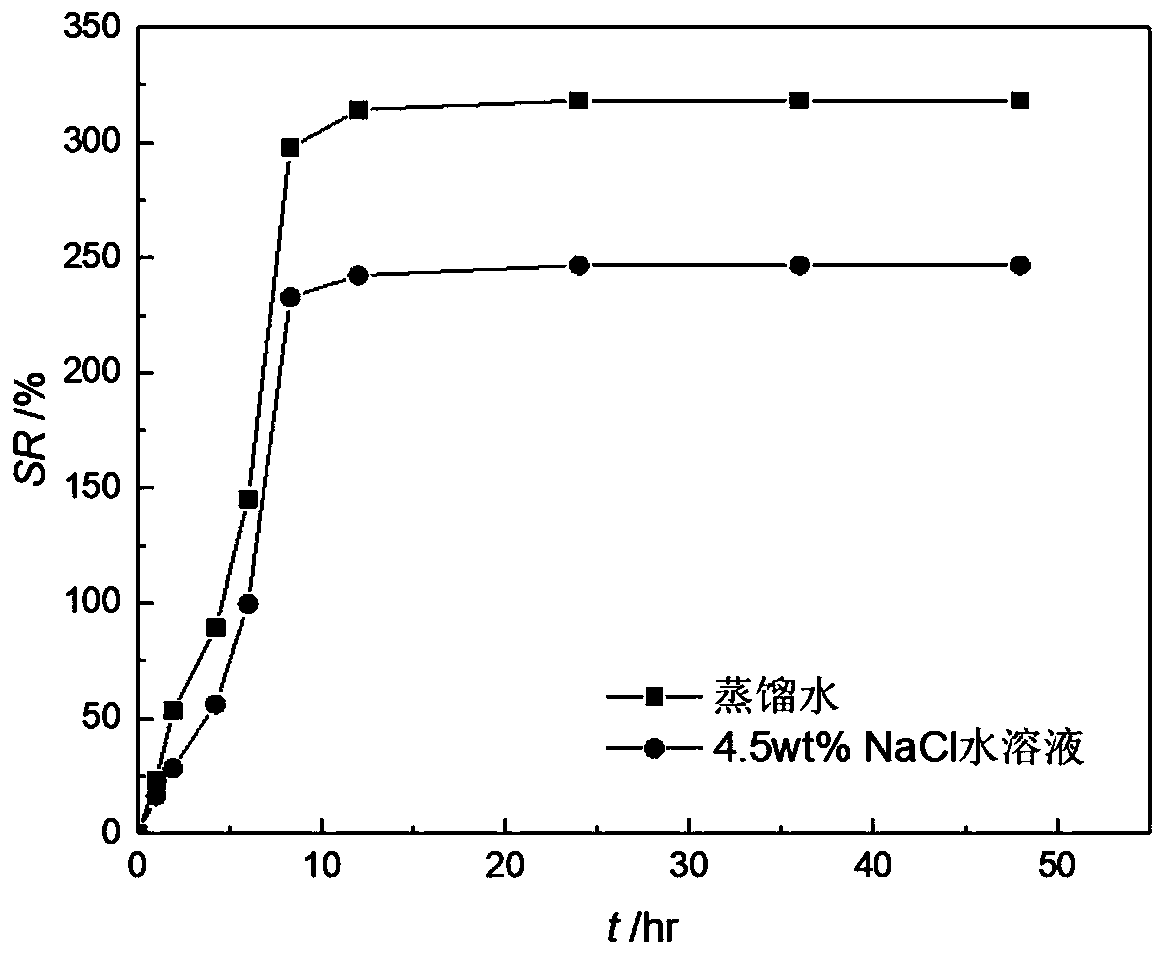

[0042] Accurately weigh 3g of AJ-I and place it in a beaker, add 1000mL of distilled water or 4.5% NaCl aqueous solution, take out AJ-I at regular intervals, absorb the surface moisture with filter paper, weigh the mass of AJ-I after swelling, and calculate the water content at different times The swelling ratio SR of the gel is used to draw the swelling rate curve.

[0043] The formula for calculating the swelling ratio is shown in formula [1]

[0044] SR=(m t -mo ) / m o ,[1]

[0045] In formula [1], SR is the swelling ratio of AJ-I, %; m o is the mass of AJ-I before water absorption, g; m t is the mass of AJ-I after absorbing water, g.

[0046] figure 1 The swelling properties of AJ-1 and its resistance to saline solution were revealed. By doping the flexible polymer HPAA in the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com