Metal grinding disc for stone grinding and polishing and manufacturing process thereof

A manufacturing process and technology for grinding discs, applied in manufacturing tools, metal processing equipment, grinding/polishing equipment, etc., can solve problems such as the inability to reuse the grinding disc base, the uneven weight distribution of the grinding disc base, and the difficulty in meeting environmental protection requirements, etc. Achieve the effect of improving uniformity and processing accuracy, simple and reliable structure, convenient processing and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

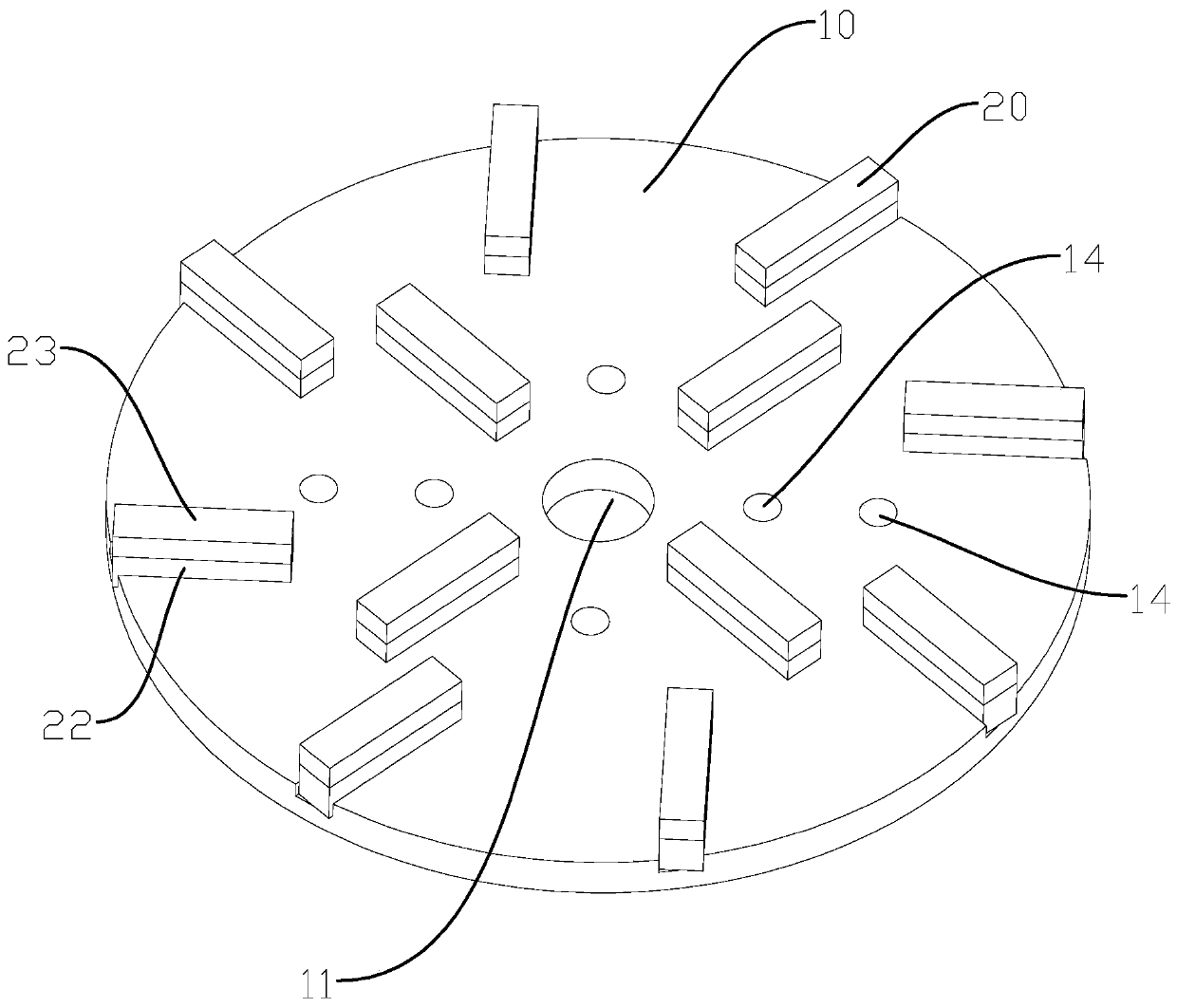

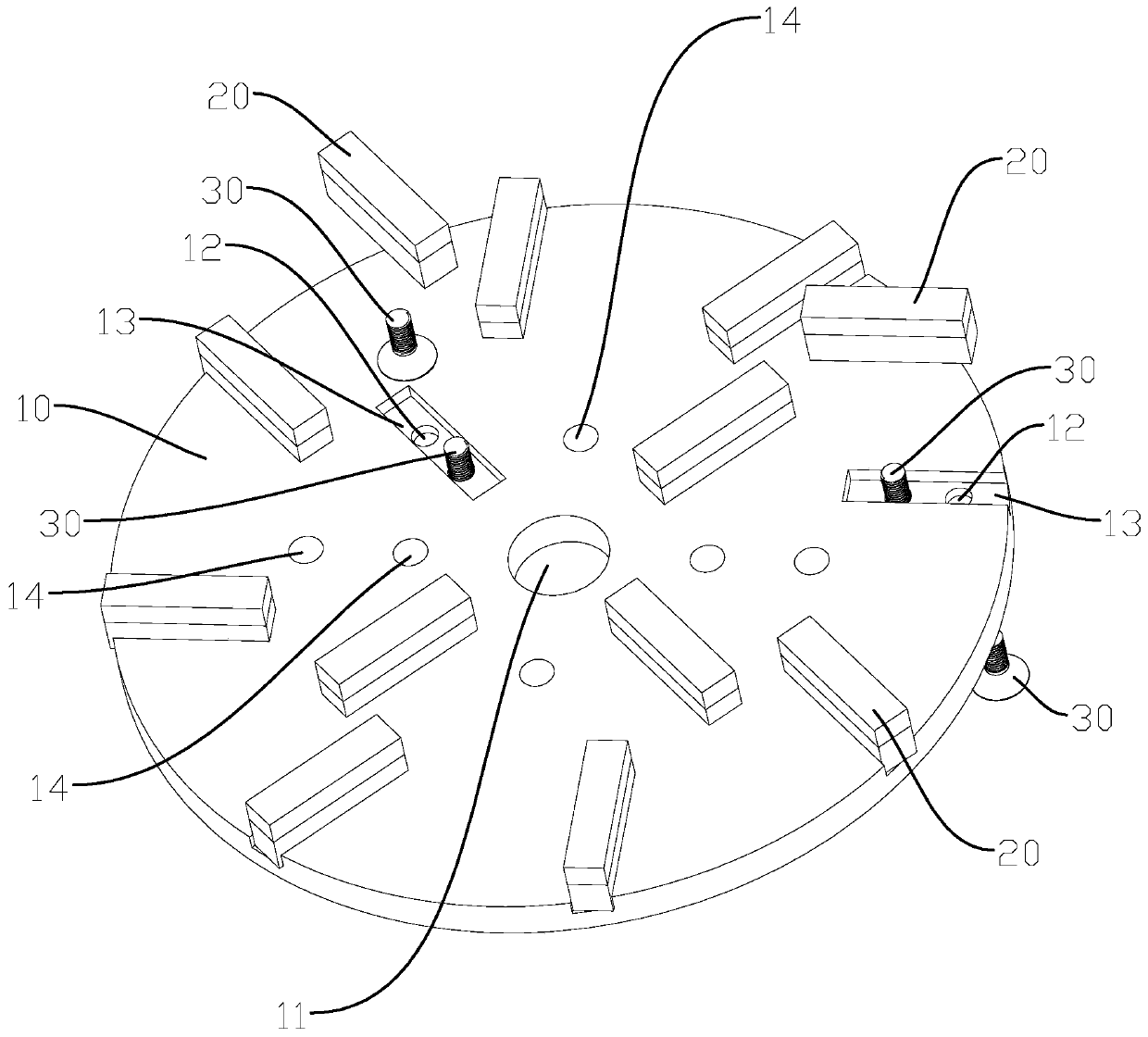

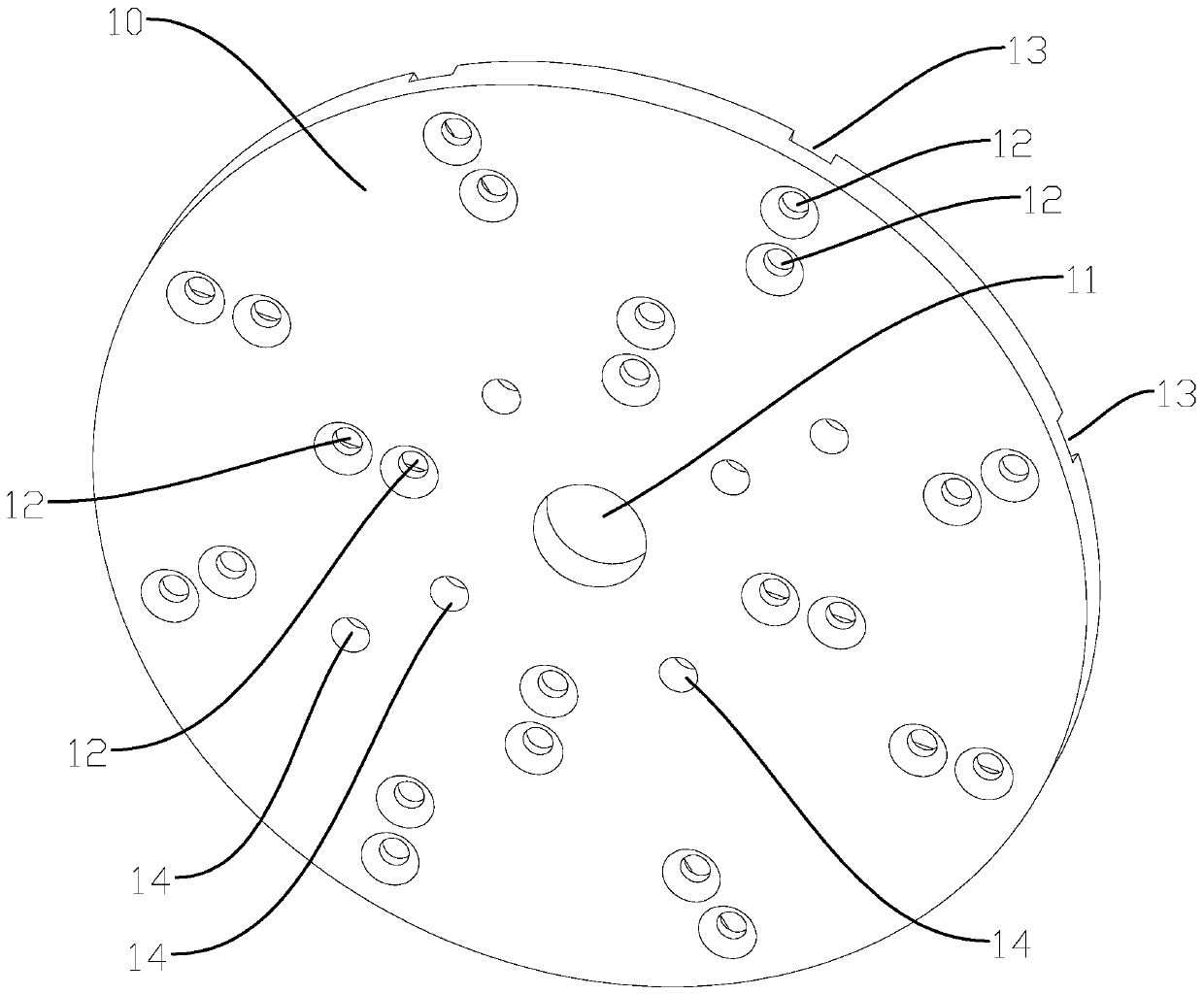

[0028] refer to Figure 1 to Figure 5 , a preferred embodiment of the metal grinding disc for stone grinding and polishing in the present invention, a metal grinding disc for stone grinding and polishing, comprising a grinding disc base 10 and a cutter head 20, the center of the grinding disc base 10 is provided with a mounting hole that is compatible with a stone polishing machine 11. A first screw hole 12 is provided on the grinding disc base 10, a second screw hole 21 is provided on the cutter head 20, and the cutter head 20 is threaded through the locking screw in the first screw hole 12 and the second screw hole 21 at the same time. 30 is fixedly installed on the front end of the grinding disc base 10. In the present invention, the locking screw 30 is used to install the cutter head 20 on the grinding disc base 10. The structure is simple and reliable, and it is convenient for processing and assembly. After the cutter head 20 is worn out, the cutter head 20 can be easily ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com