Automatic batch assembling equipment for metal pen caps

A technology for assembling equipment and pen caps, which is applied to metal processing equipment, welding equipment, resistance welding equipment, etc., and can solve the problems of low quality of semi-finished pen caps, offset or even separation of shrapnel caps, and production of defective products, so as to avoid convex hull deviation. The effect of shifting dislocation, saving manpower and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

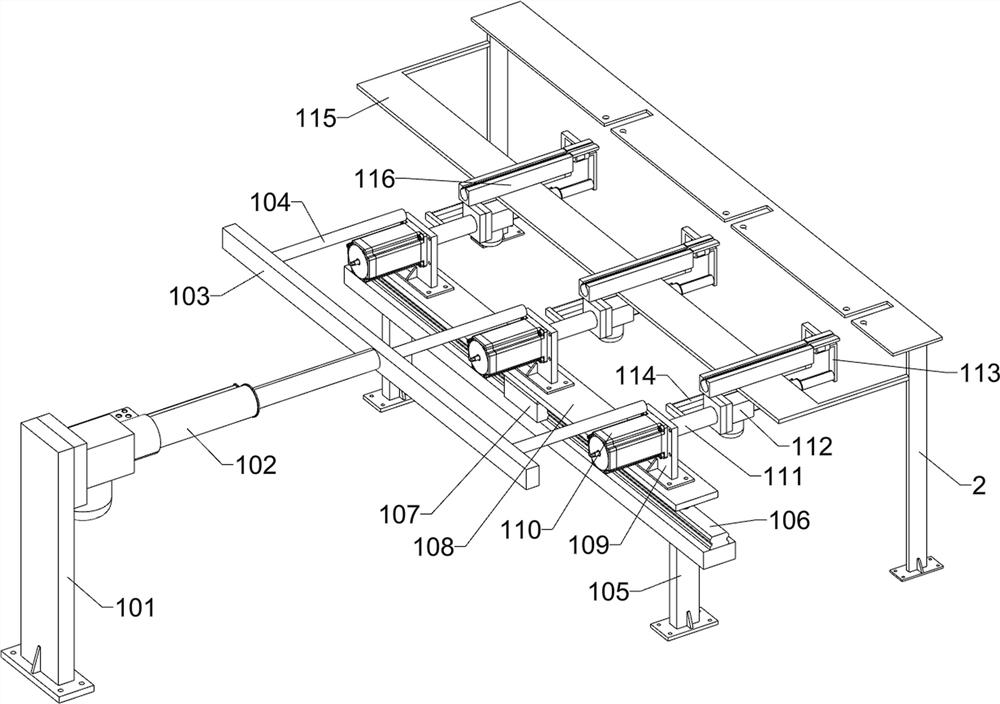

[0033] A metal pen cap automatic batch assembly equipment, such as Figure 1-11 As shown, it includes a base frame 1, a first support frame 2, a first fixing frame 3, a second fixing frame 4, an automatic spot welder 5, a collection box 6, a pen cover conveying assembly and an adhesive assembly; A first support frame 2 is fixedly connected to the right part of the side; a first fixing frame 3 is fixedly connected to the right part of the upper side of the bottom frame 1; Three equidistant second fixing frames 4 are connected; an automatic spot welding machine 5 is installed on the lower side of each second fixing frame 4; A pen cover conveying component is installed; an adhesive component is installed on the upper right part of the bottom frame 1 ; the adhesive component is connected with the first support frame 2 and the first fixing frame 3 .

[0034] The pen cover conveying assembly includes a first support plate 101, a first electric push rod 102, a first fixing plate 103...

Embodiment 2

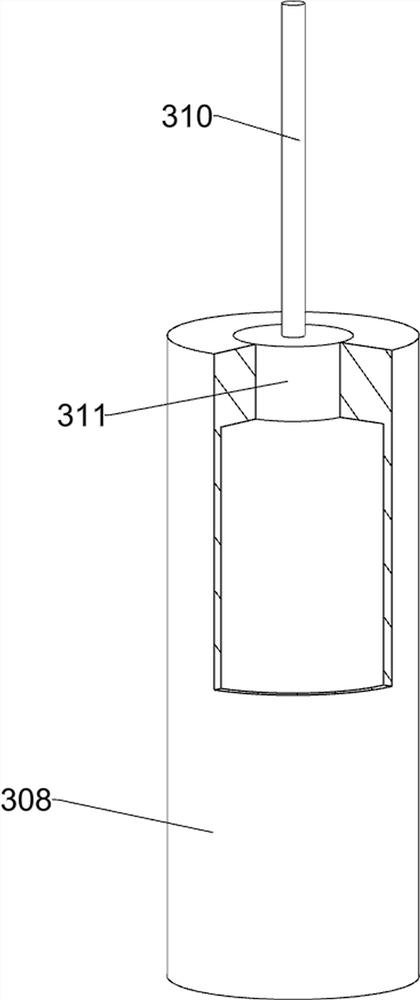

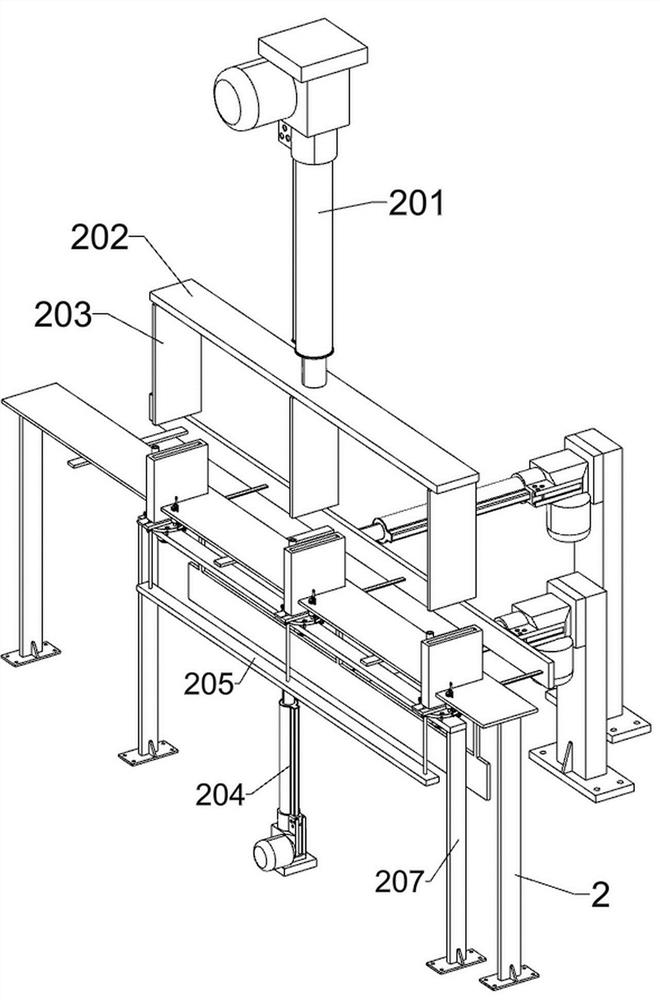

[0044] On the basis of Example 1, as Figure 12-14 As shown, it also includes a glue drop assembly; the upper part of the first fixing frame 3 is installed with a glue drop assembly; the glue drop assembly includes a U-shaped frame 301, a seventh electric push rod 302, an eighth fixing plate 303, and a fourth fixing frame 304 , the second glue liquid cylinder 305, the conduit 306, the second return spring 307, the glue dispensing head 308, the cross 309, the third fixing rod 310 and the second piston 311; the upper part of the first fixing frame 3 is fixed with a U-shaped frame 301; The seventh electric push rod 302 is fixedly connected to the lower side of the U-shaped frame 301; the telescopic end of the seventh electric push rod 302 is fixed to the eighth fixing plate 303; The lower part of the three fourth fixing frames 304 is fixed with a second glue liquid cylinder 305; the upper part of the three second glue liquid cylinders 305 is connected with a conduit 306; the lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com