PPR all-pass type cut-off valve

A shut-off valve, through-type technology, applied in sliding valves, valve details, valve devices, etc., can solve the problems of inability, prone to displacement, poor flow control ability in the pipeline, etc. good flow effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

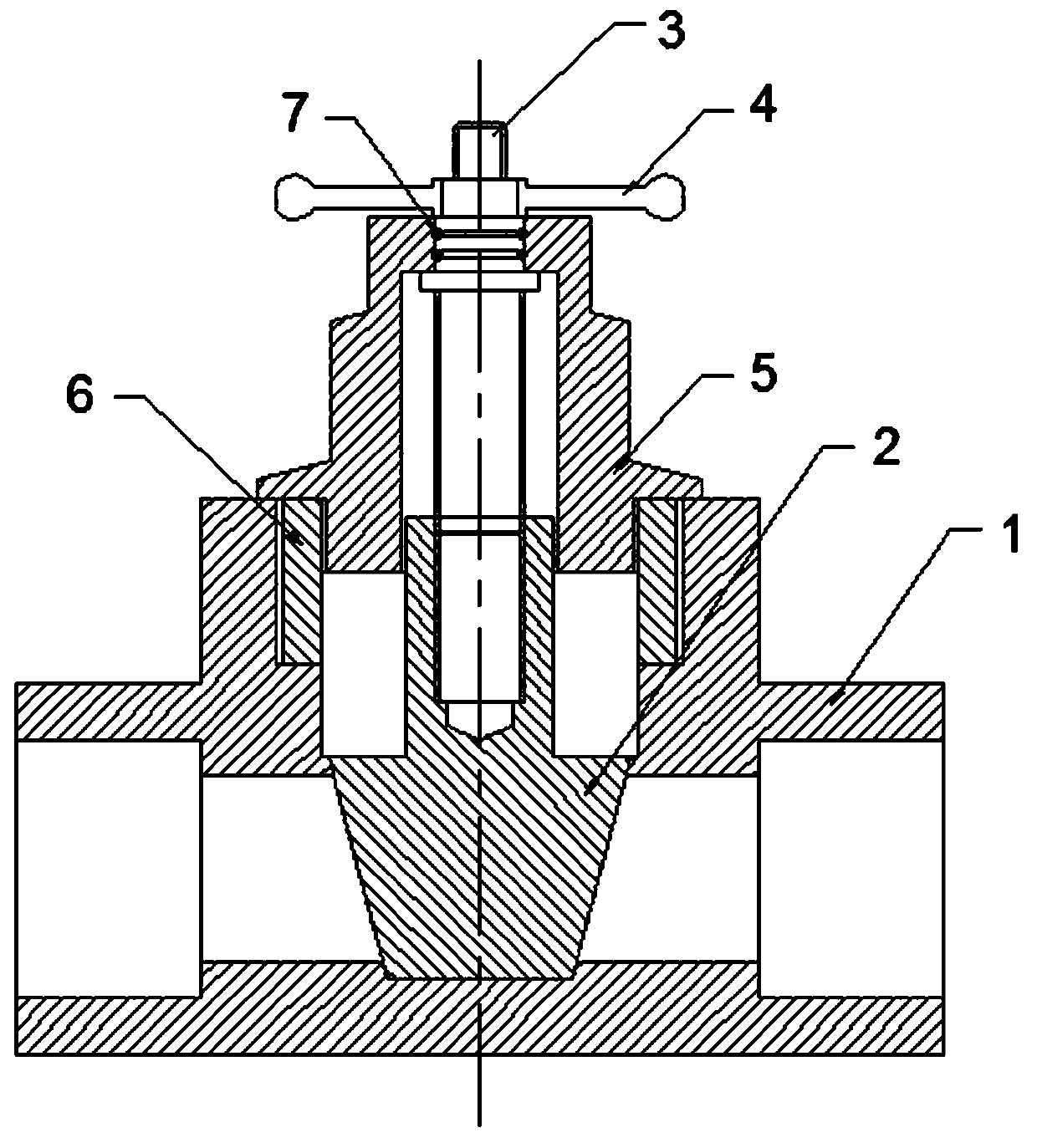

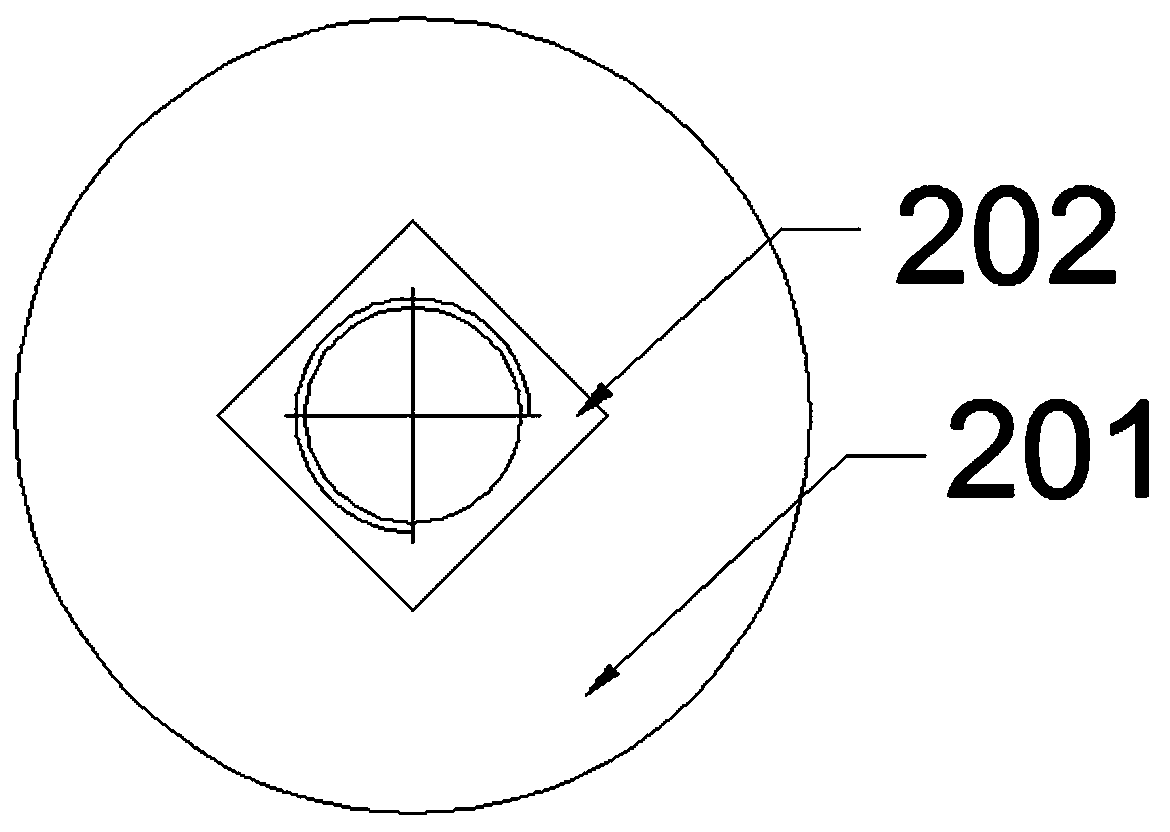

[0022] Such as Figure 1 to Figure 5 As shown, a PPR full-way globe valve includes a valve body 1, a valve core 2, a rotating shaft 3, a hand wheel 4 and a valve cover 5, the rotating shaft 3 is rotatably connected to the valve cover 5, and the hand wheel 4 is sleeved on the rotating shaft 3, the valve core 2 is connected with the rotating shaft 3, the valve cover 5 is connected with the valve body 1, and the pipeline in the valve body 1 is a straight full-through type pipeline. The pipeline in the valve body 1 is provided with a conical counterbore, and the valve cover 5 is provided with a prismatic counterbore 501 and a shaft through hole 502 . The spool 2 includes a conical seal 202 and a prismatic connecting rod 201, the conical sealing 202 has the same taper as the coni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com