Polyolefin elastomer and preparation method thereof

A polyolefin elastomer, alpha olefin technology, applied in the field of polyolefin elastomer and its preparation, can solve the problems of time-consuming, complicated operation, low efficiency and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] One aspect of the present invention provides a method for preparing a polyolefin elastomer, the molecular weight of the polyolefin elastomer has a bimodal distribution, the method comprises: in an organic solvent, in the presence of a catalyst and hydrogen, ethylene, alpha olefin and optionally polymerizing a cyclic olefin;

[0023] Wherein, the catalyst contains a main catalyst and an activator, and the activator includes one or more of aluminum-containing compounds and optionally contains an organoboron compound;

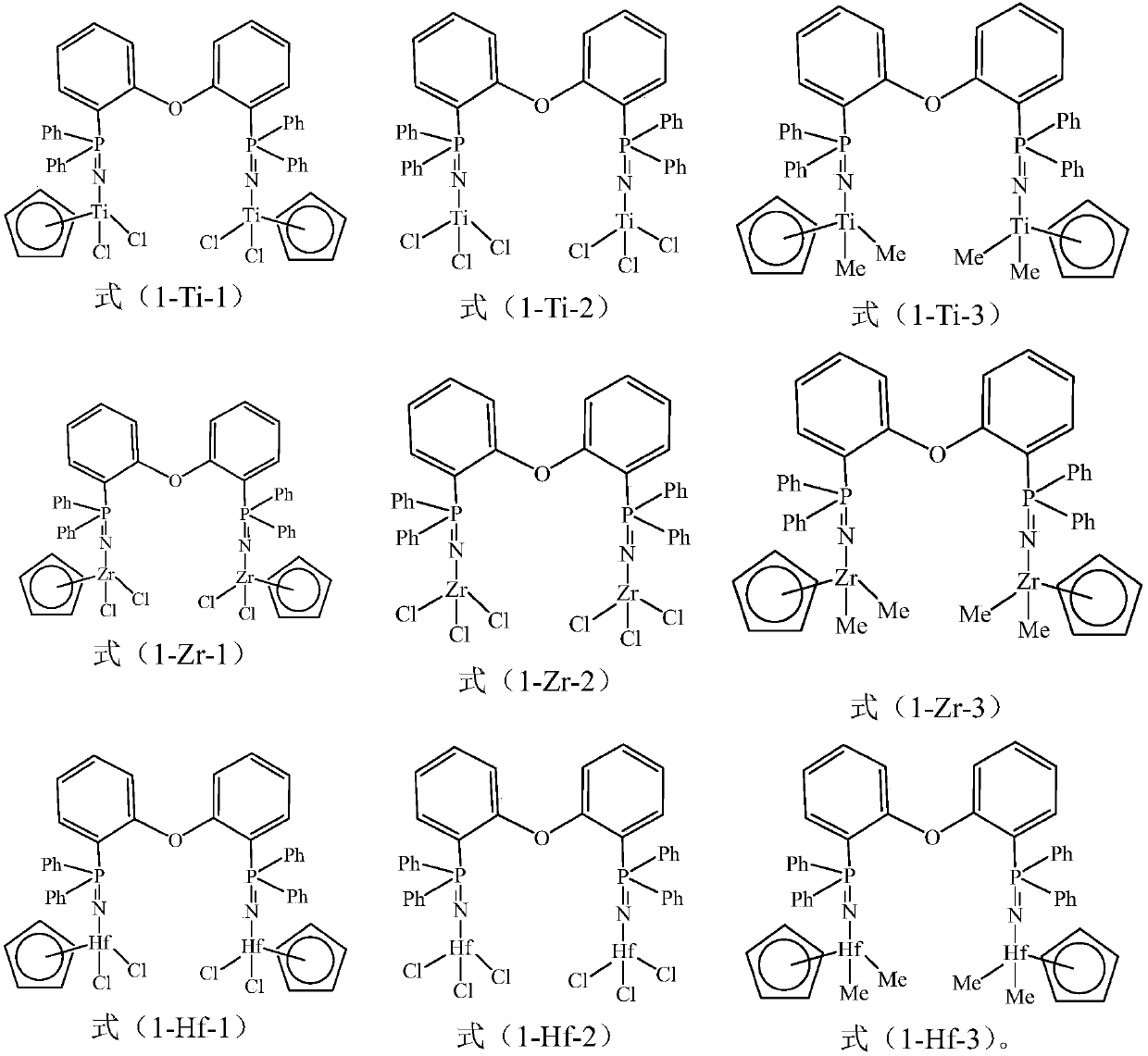

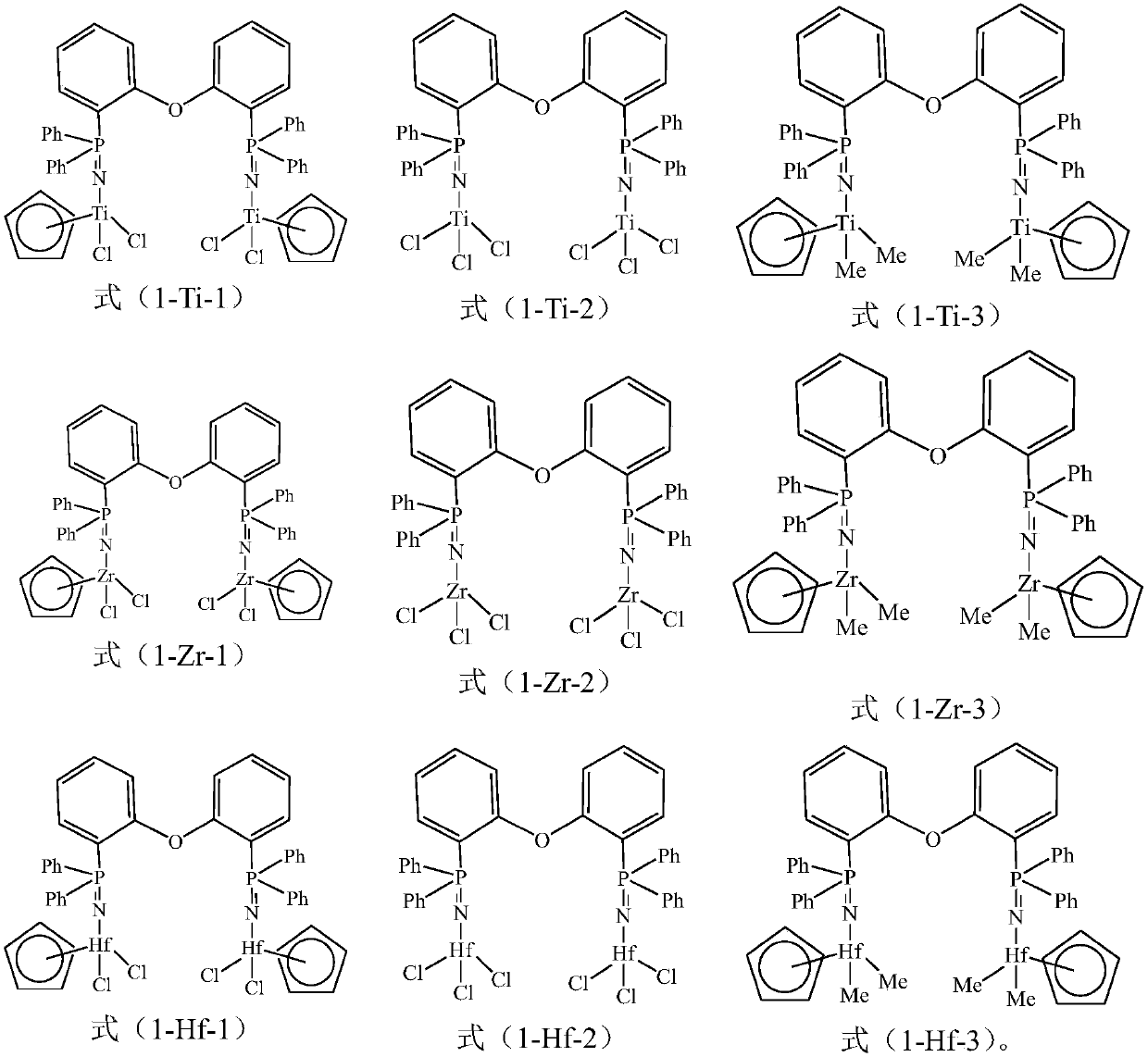

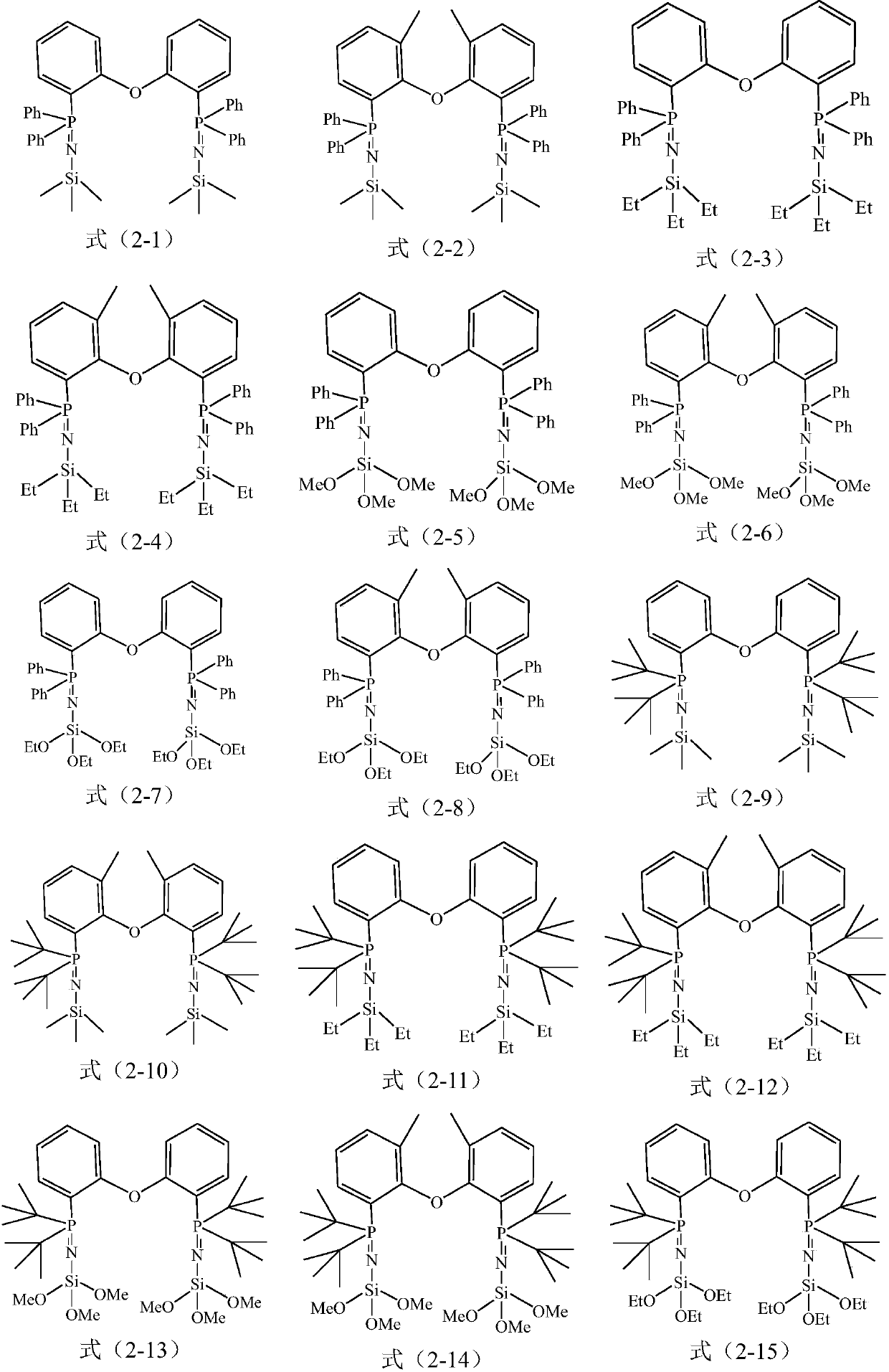

[0024] The main catalyst is one or more of the early transition metal compounds represented by formula (1) or their crystals;

[0025] Formula 1)

[0026] Among them, R 1 , R 2 , R 3 and R 4 each independently selected from H, C 1-20 Hydrocarbyl, C 1-20 alkoxy and halogen;

[0027] R 1 and R 2 each independently selected from H, C 1-4 Hydrocarbyl and substituted or unsubstituted C 6-12 The aryl, the substituted C 6-12 The substituent on the a...

Embodiment 1

[0261] This example is used to illustrate the early transition metal compound and its preparation method, intermediate and single crystal of the present invention.

[0262]

[0263] Prepare according to the above reaction formula, specifically:

[0264] (1) Diphenyl ether (0.02mol) was diluted in hexane (50mL), and at -78°C, a hexane solution of n-BuLi (42mmol) was added dropwise (completed within about 5min), reacted for 1h, and then Warm up to room temperature (about 25°C), and continue stirring for 16h;

[0265] (2) Then add 15 mL of diphenylphosphine chloride (42 mmol) in n-hexane solution dropwise to the reaction system of step (1) in an ice-water bath (complete addition within about 5 min), and then continue at room temperature (about 25 ° C) ) under stirring reaction for 16h; the solvent was removed by rotary evaporation to obtain a light yellow viscous oil, which was washed with acetone and dried in vacuo to obtain 9.4g white powder, which was the compound shown in...

Embodiment 2

[0270] This example is used to illustrate the early transition metal compound of the present invention and its preparation method and intermediate.

[0271] According to the method described in Example 1, the difference is that in step (4): the compound (1 mmol) shown in formula (2-1) was dissolved in 10 mL of toluene, and 5 mL of TiCl was added dropwise under magnetic stirring 4 (2mmol) toluene solution, then heated to 110 ° C and refluxed for 12h; after the reaction was completed, the solvent toluene was removed by rotary evaporation under reduced pressure, and the crude product was washed 3 times with pentane, and vacuum-dried to obtain the product. 1 The obtained compound was identified by H NMR as formula (1-Ti-2).

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com