A kind of additive wastewater treatment process

A technology for wastewater treatment and additives, which is used in water/sewage multi-stage treatment, oxidized water/sewage treatment, special compound water treatment, etc., and can solve problems such as dependence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

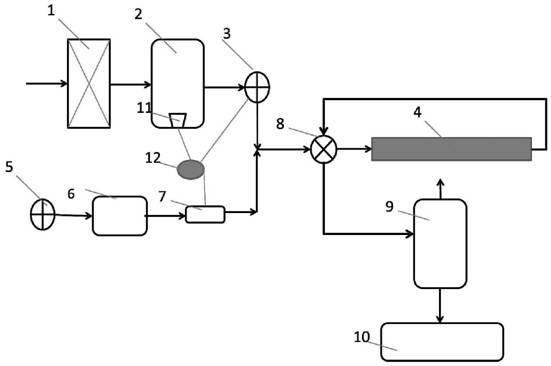

[0034] like figure 1 As shown, it is a tubular continuous reaction device of the present invention, and the device includes a filter 1, a sewage buffer tank 2, a sewage pump 3, a free radical generator 4, an air compressor 5, an air buffer tank 6, and an air flow meter 7 , heat exchanger 8, high-pressure separation tank 9, liquid storage tank 10, the air compressor 5 is connected with the inlet of the air pressure buffer tank 6, and the air buffer tank 6 is connected with the free radical by the pipeline provided with the air flow meter 7 The generator 4 is connected, the filter 1 is connected with the sewage buffer tank 2 through pipelines, the sewage buffer tank 2, the sewage pump 3 and the free radical generator 4 are connected in sequence, and the entrance of the free radical generator 4 is provided with a heat exchanger for 8 The reactor output stream and the feed stream exchange heat, and the outlet of the free radical generator 4 is connected to the high-pressure separa...

Embodiment 2

[0037] Preparation of Catalyst A:

[0038] 1) claim that 261g ruthenium chloride trihydrate is dissolved in 10L deionized water to form solution A;

[0039] 2) Weigh 1Kg of coconut shell activated carbon, place it in a muffle furnace at 100°C for high temperature activation for a period of time, and cool to room temperature to obtain activated carrier B;

[0040] 3) Add 500g of activated carrier B to 2L of solution A and soak for 5 hours, and filter to obtain catalyst precursor C;

[0041] 4) Precursor C was dried at 80° C. for 5 hours, and then calcined at 800° C. for 8 hours to obtain catalyst A. According to detection and analysis, the loading amount of ruthenium was 0.21 wt%.

Embodiment 3

[0043] Preparation of Catalyst B:

[0044] 1) Weigh 250g of manganese nitrate and dissolve it in 5L of deionized water, then add 150mL of 30% hydrogen peroxide, and react at 30°C for 1 hour to obtain reaction solution A;

[0045] 2) Add 1Kg ZSM-5 molecular sieve to the reaction solution A and soak for 5 hours, filter and dry to obtain catalyst precursor A;

[0046] 3) Dissolve 26g of cobalt chloride and 272g of zinc chloride in 5L of deionized water to obtain solution B, place precursor A in solution B and immerse for 5 hours to obtain catalytic precursor B;

[0047] 4) Dry the catalyst precursor B at 80°C for 3 hours, then put it into a muffle furnace, and calcinate it at 600°C for 8 hours to obtain catalyst B. After detection and analysis, the content of the catalyst active component Mn is 1.12wt %, the content of Co is 0.12wt%, and the content of zinc is 2.08wt%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com