Spiral bevel gear femtosecond laser processing system and fine correction method thereof

A technology of femtosecond laser processing and spiral bevel gear, which is applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve problems such as complex tooth surface structure, difficult laser beam focusing, immature three-dimensional processing of metal, etc., to achieve linkage Good performance, high processing precision, improving processing efficiency and processing reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

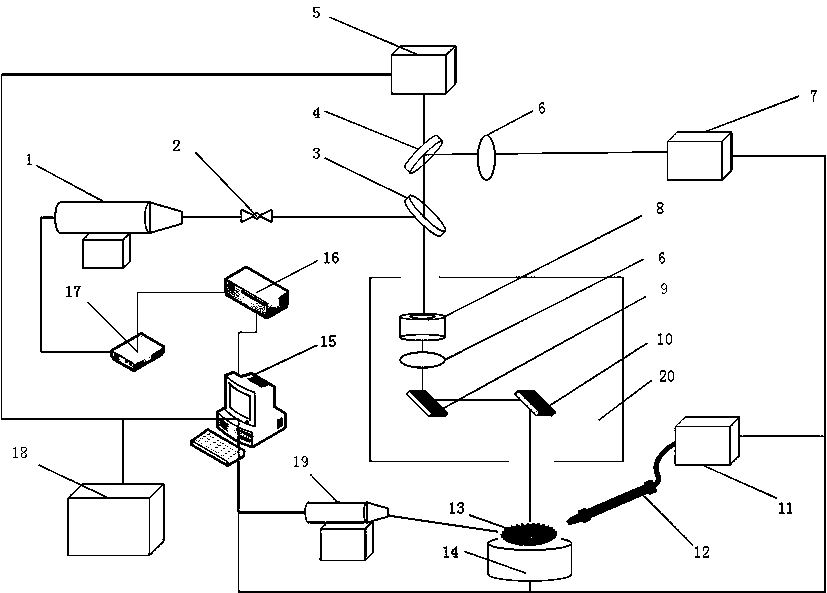

[0025] Such as figure 1 As shown, the present invention provides a femtosecond laser processing system for spiral bevel gears, including a femtosecond laser system, a light guide assembly, a three-dimensional galvanometer system 20, an illumination system 5, a precision movement system, and a CCD monitoring system 7; wherein the femtosecond laser The system includes a femtosecond laser 17, a femtosecond laser ablation head 1, and a laser control operation platform 16; the light guide assembly and the three-dimensional galvanometer system 20 together form an optical path; the laser emitted by the femtosecond laser system and the illumination light emitted by the lighting system 5 are both Transmission along the light path; the precision movement system includes a precision three-dimensional movement axis and a control platform 14, which are arranged at the exit of the light path, and a spiral bevel gear 13 is fixed on the precision three-dimensional movement axis and the control...

specific Embodiment approach

[0030]S1: Three-dimensional measurement and processing of the spiral bevel gear to be processed. After the milling of the spiral bevel gear is completed, mesh the tooth surface of the spiral bevel gear along the tooth length and tooth height direction of the root cone, and measure it after positioning through the three-dimensional measurement and processing system 18 to measure the actual tooth surface mesh Grid node coordinates and normal vectors; the three-dimensional measurement and processing system 18 can be a bridge-type three-coordinate measuring machine or a gear measurement center, which can substitute the theoretical coordinates and normal vectors of the grid nodes of the spiral bevel gear tooth surface into its preset measurement coordinate system to obtain the actual tooth surface grid node coordinates and normal vectors, so before this, the theoretical three-dimensional model of the spiral bevel gear is established according to the tooth surface equation, and the t...

Embodiment 2

[0037] The difference between this embodiment and Embodiment 1 is that the femtosecond laser correction system and fine correction method provided in this embodiment are applied to the fine correction of the tooth surface of the spiral bevel gear, and the structure of the femtosecond laser correction system predicts the steps of the fine correction method and Example 1 is almost the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com