Polymer electrolyte with flame retardant function and preparation and application thereof

A technology of polymers and electrolytes, applied in electrolytes, non-aqueous electrolytes, solid electrolytes, etc., can solve the problems of inability to effectively inhibit the growth of lithium dendrites and uneven distribution of inorganic fillers, achieve excellent thermal stability, and solve poor mechanical properties. Good, good mechanical properties and the effect of flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0067] Correspondingly, taking lithium-ion batteries as the planned application object as an example, the preparation method of the polymer electrolyte with flame-retardant function may include the following steps:

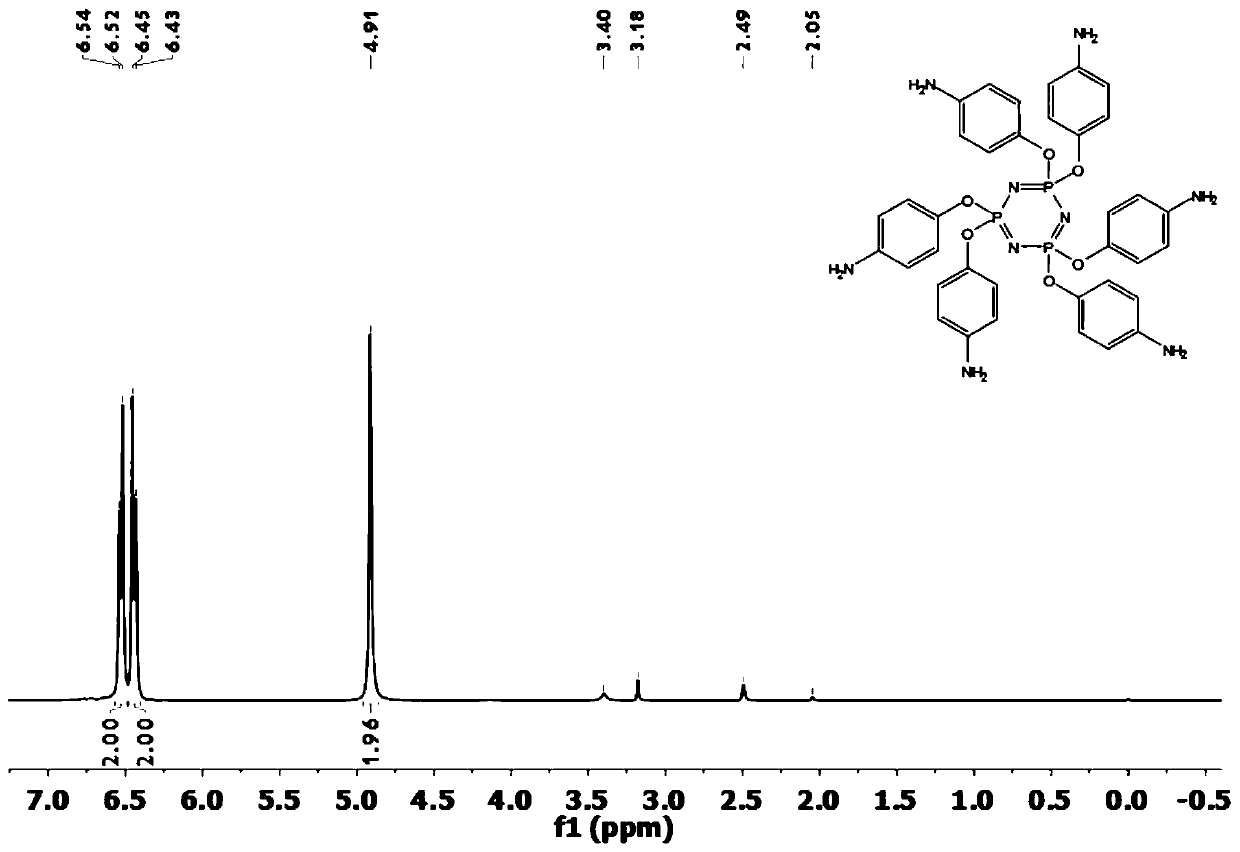

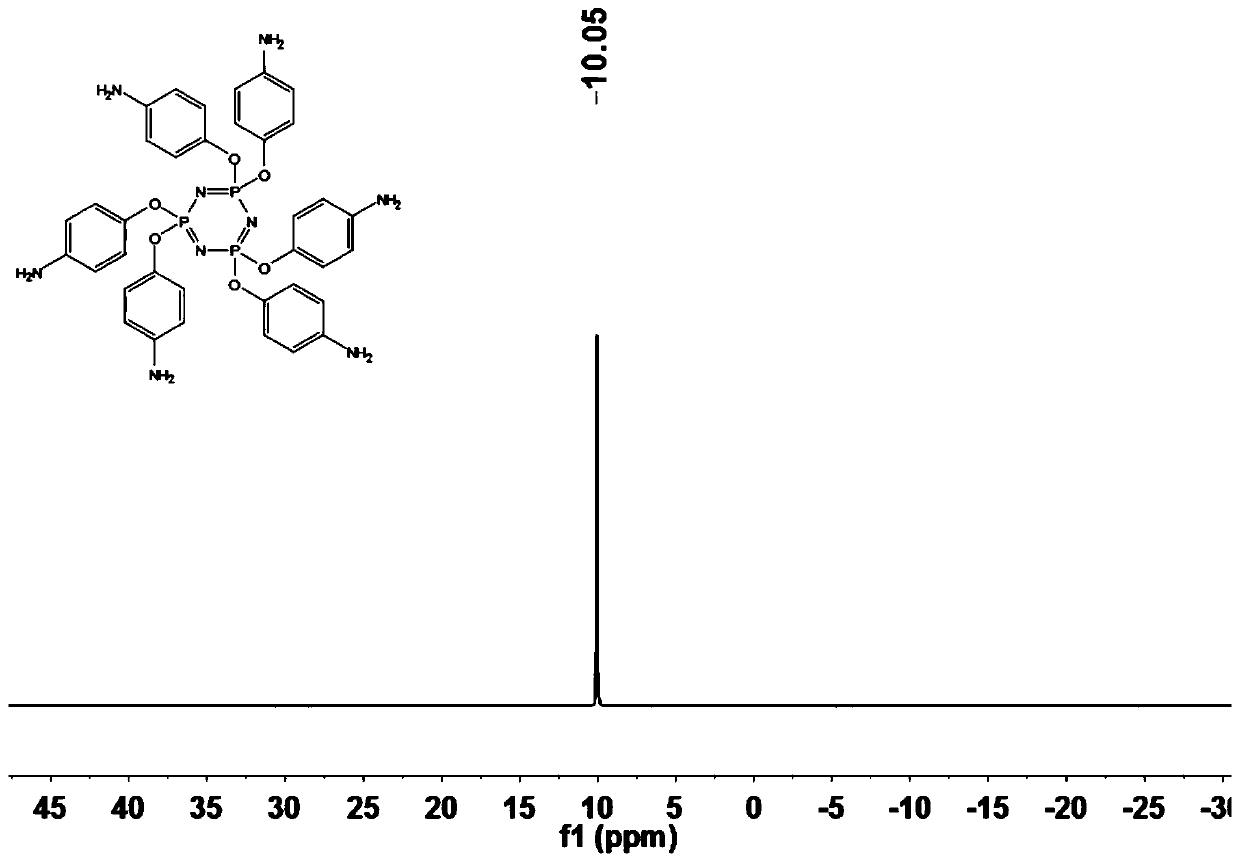

[0068] I, the synthesis of flame retardant structure hexaphenol aminocyclophosphazene HCP, specifically include:

[0069] (1) dissolving hexachlorocyclotriphosphazene and acetaminophen in an organic solvent, adding alkali, and stirring under reflux reaction to obtain a reaction solution;

[0070] (2) The reaction solution described in step (1) is poured into a precipitating agent for precipitation, and is filtered and dried to obtain hexaacetamidophenol cyclophosphazene;

[0071] (3) dissolving the hexaacetamidophenol cyclic phosphazene described in step (2) in an organic solvent, adding alkali, and stirring and reflux reaction, and filtering to obtain hexaphenolaminocyclic phosphazene HCP after the reaction;

[0072] II. Synthesis of cross-linking agent polyethy...

Embodiment 1

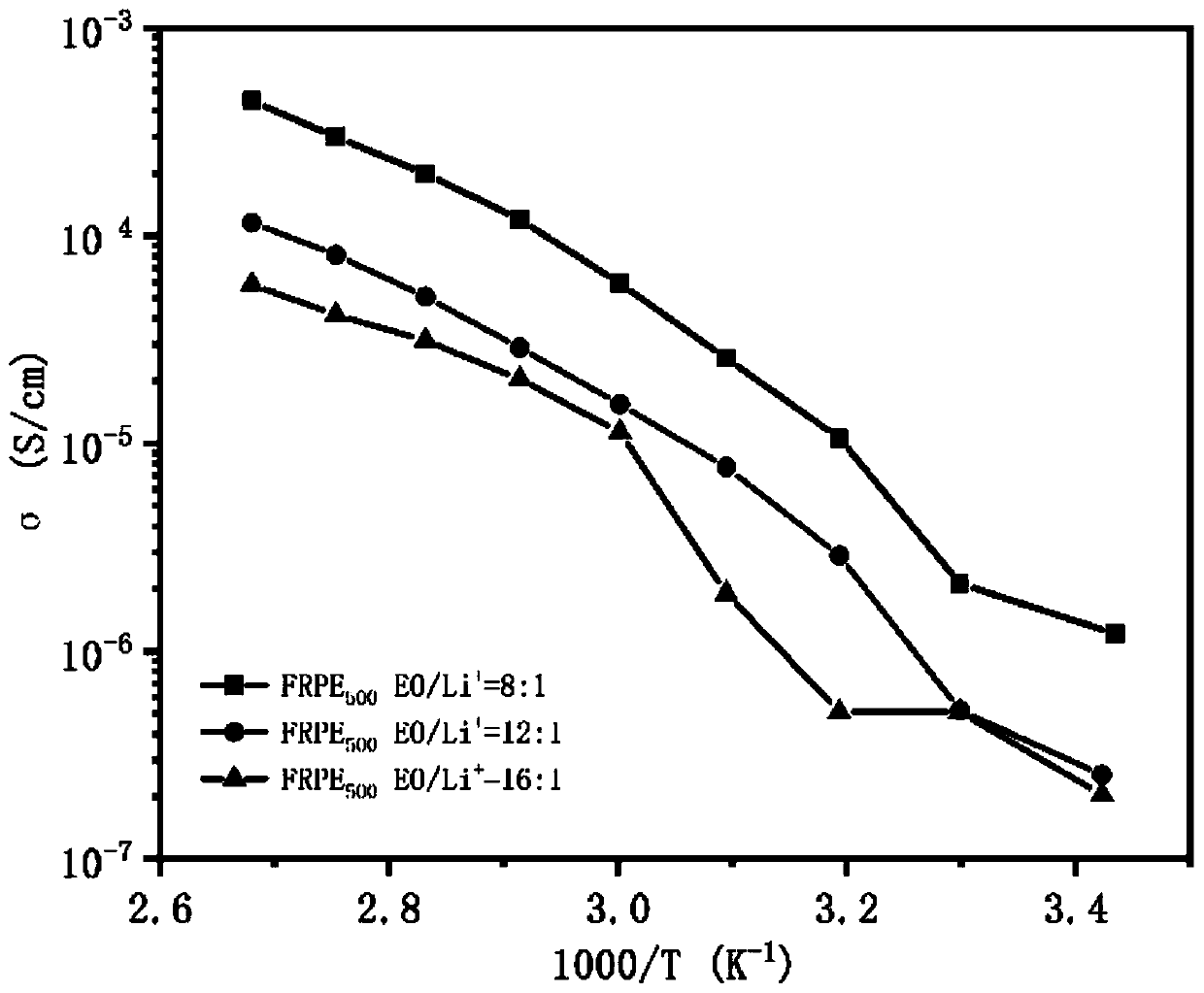

[0094] Hexaphenol aminocyclophosphazene HCP-polyethylene glycol diglycidyl ether PEGDE 200 Flame retardant polymer electrolyte.

[0095]The preparation method of the flame-retardant polymer electrolyte is as follows: 5.0 g of hexachlorocyclotriphosphazene and 17.4 g of 4-acetaminophenol were dissolved in 200 mL of acetone solution, and 29.9 g of potassium carbonate powder was added. Under argon protection, with mechanical stirring, the reaction was refluxed at 60° C. for 5 days. After the reaction, the remaining reaction solution was poured into water for precipitation, stirred and washed. Filter, wash with water three times, suck dry, and dry in a vacuum oven at 50°C for 48 hours to obtain white crystals. Dissolve 25.0 g of hexaacetylphenol-based cyclophosphazene in 300 mL of methanol, add dropwise an aqueous solution in which 58.0 g of NaOH is dissolved, and raise the temperature to 90° C. under the protection of argon, and stir and reflux for 5 days. After the reaction, ...

Embodiment 2

[0098] Hexaphenol aminocyclophosphazene HCP-polyethylene glycol diglycidyl ether PEGDE 4000 Flame retardant polymer electrolyte.

[0099] The preparation method of the flame-retardant polymer electrolyte is as follows: 5.0 g of hexachlorocyclotriphosphazene and 17.4 g of 4-acetamidophenol were dissolved in 200 mL of tetrahydrofuran solution, and 29.9 g of potassium carbonate powder was added. Under argon protection, with mechanical stirring, the reaction was refluxed at 60° C. for 1 day. After the reaction, the remaining reaction solution was poured into water for precipitation, stirred and washed. Filter, wash with water three times, suck dry, and dry in a vacuum oven at 50°C for 48 hours to obtain white crystals. Dissolve 25.0 g of hexaacetylphenol-based cyclophosphazene in 300 mL of methanol, add dropwise an aqueous solution in which 58.0 g of NaOH is dissolved, and raise the temperature to 100° C. under the protection of argon, and stir and reflux for 5 days. After the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Li-ion conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Li-ion conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com