A kind of organic silver/carbon nanotube composite slurry and its preparation method and application

A carbon nanotube composite and carbon nanotube technology, which is applied in nanotechnology, nanotechnology, cable/conductor manufacturing, etc., can solve the problems of resin aging and falling off, high resistivity, etc., and achieve high bonding strength, low resistivity, The effect of fast and efficient preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Preparation of organic silver / carbon nanotube composite slurry:

[0056] 1) Preparation of materials: Prepare carboxylated carbon nanotubes, silver acetate, ethylamine and ethylene glycol according to the mass ratio of 15:12:20:53;

[0057] 2) Mix ethylamine and ethylene glycol to form an organic solution, add silver acetate as a silver source to the organic solution, and form a precursor fluid containing silver acetate-ethylamine complex after ultrasonic vibration for 40 minutes;

[0058] 3) Add carboxylated carbon nanotubes to the precursor body fluid, and mechanically stir for 8 hours after ultrasonic vibration for 60 minutes to obtain organic silver / carbon nanotube composite slurry;

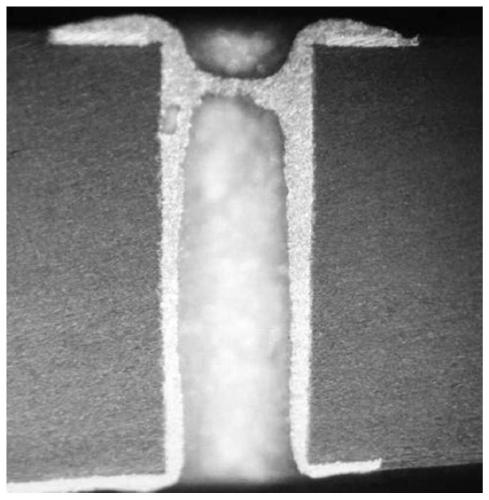

[0059] Preparation of nano conductive composite film:

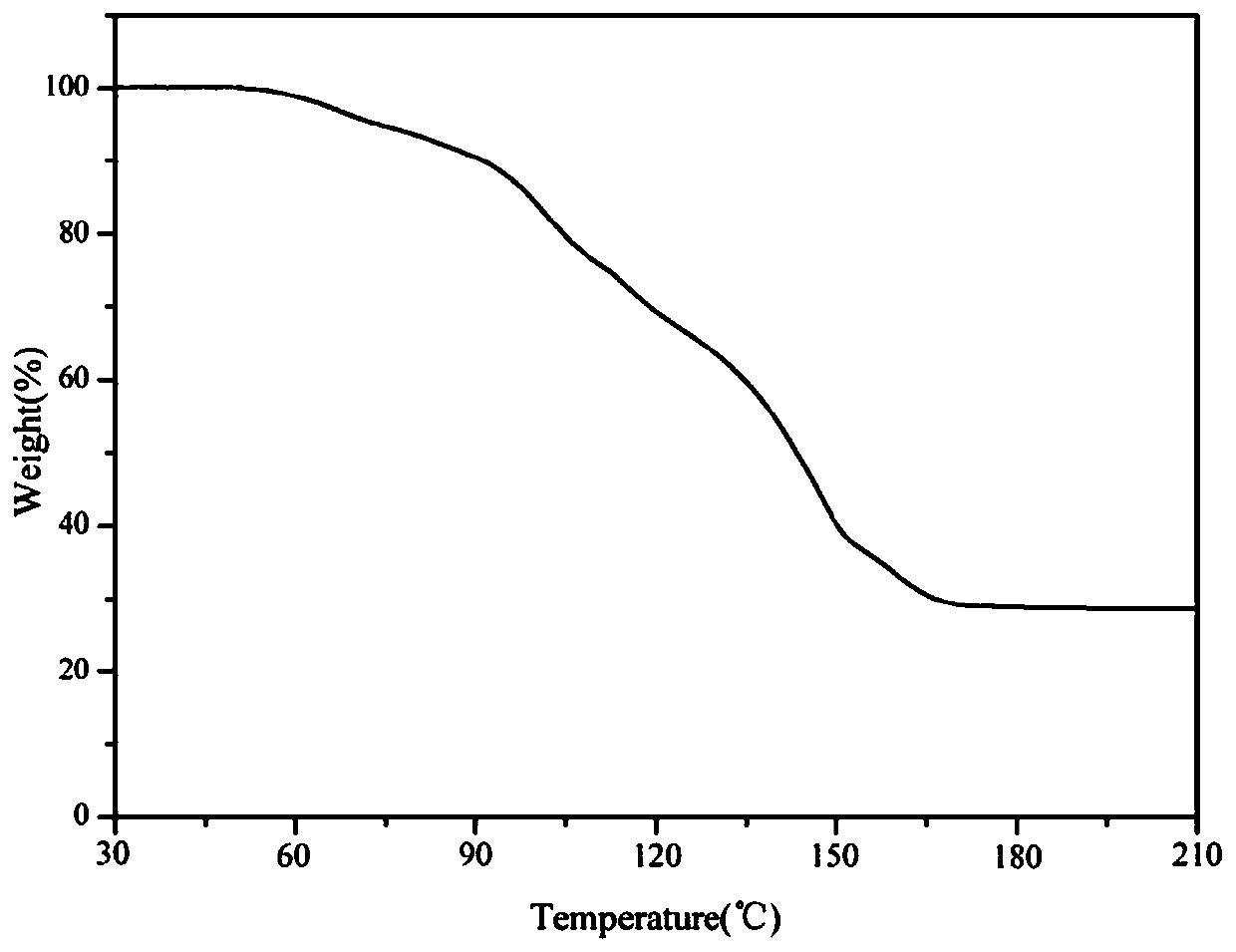

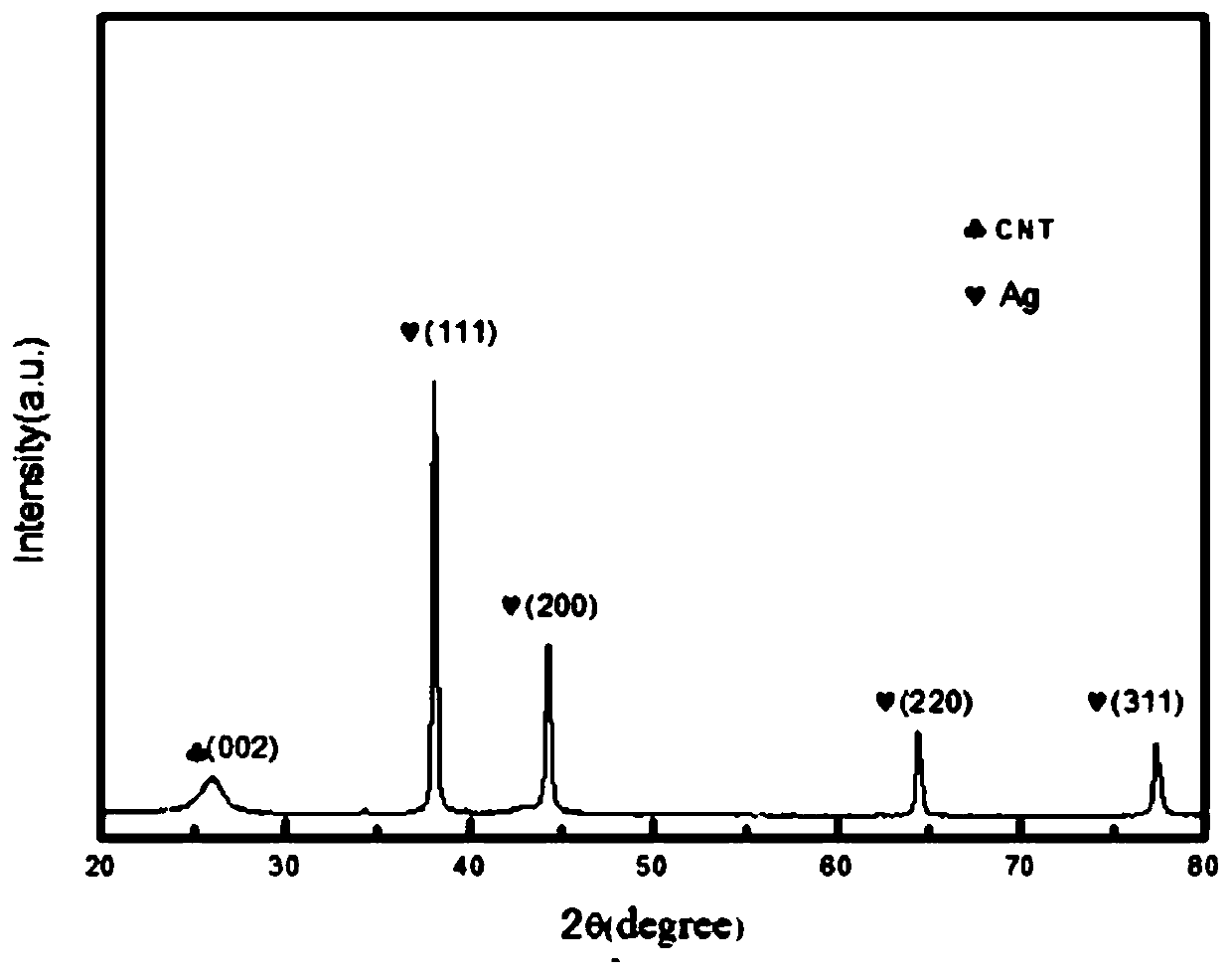

[0060] Add the prepared organic silver / carbon nanotube composite slurry dropwise into the guide hole of the printed circuit board, heat it at 120°C for 40min, and directly in-situ deposit nano-silver and carbon nanotube on the in...

Embodiment 2

[0066] Preparation of organic silver / carbon nanotube composite slurry:

[0067] 1) Preparation of materials: prepare carboxylated carbon nanotubes, silver acetate, ethylamine and ethylene glycol according to the mass ratio of 20:15:25:40;

[0068] 2) Mix ethylamine and ethylene glycol to form an organic solution, add silver acetate as a silver source to the organic solution, and form a precursor fluid containing silver acetate-ethylamine complex after ultrasonic vibration for 40 minutes;

[0069] 3) Add carboxylated carbon nanotubes to the precursor body fluid, and mechanically stir for 8 hours after ultrasonic vibration for 60 minutes to obtain organic silver / carbon nanotube composite slurry;

[0070] Preparation of nano conductive composite film:

[0071] Add the prepared organic silver / carbon nanotube composite slurry dropwise into the guide hole of the printed circuit board, heat at 150°C for 60 minutes, and directly deposit nano-silver and carbon nanotubes on the inner w...

Embodiment 3

[0077] Preparation of organic silver / carbon nanotube composite slurry:

[0078] 1) Preparation of materials: prepare carboxylated carbon nanotubes, silver acetate, ethylamine and ethylene glycol according to the mass ratio of 18:15:22:45;

[0079] 2) Mix ethylamine and ethylene glycol to form an organic solution, add silver acetate as a silver source to the organic solution, and form a precursor fluid containing silver acetate-ethylamine complex after ultrasonic vibration for 40 minutes;

[0080] 3) Add carboxylated carbon nanotubes to the precursor body fluid, and mechanically stir for 8 hours after ultrasonic vibration for 60 minutes to obtain organic silver / carbon nanotube composite slurry;

[0081] Preparation of nano conductive composite film:

[0082] Add the prepared organic silver / carbon nanotube composite slurry dropwise into the guide hole of the printed circuit board, heat at 130°C for 50 minutes, and directly deposit nano-silver and carbon nanotubes on the inner w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com