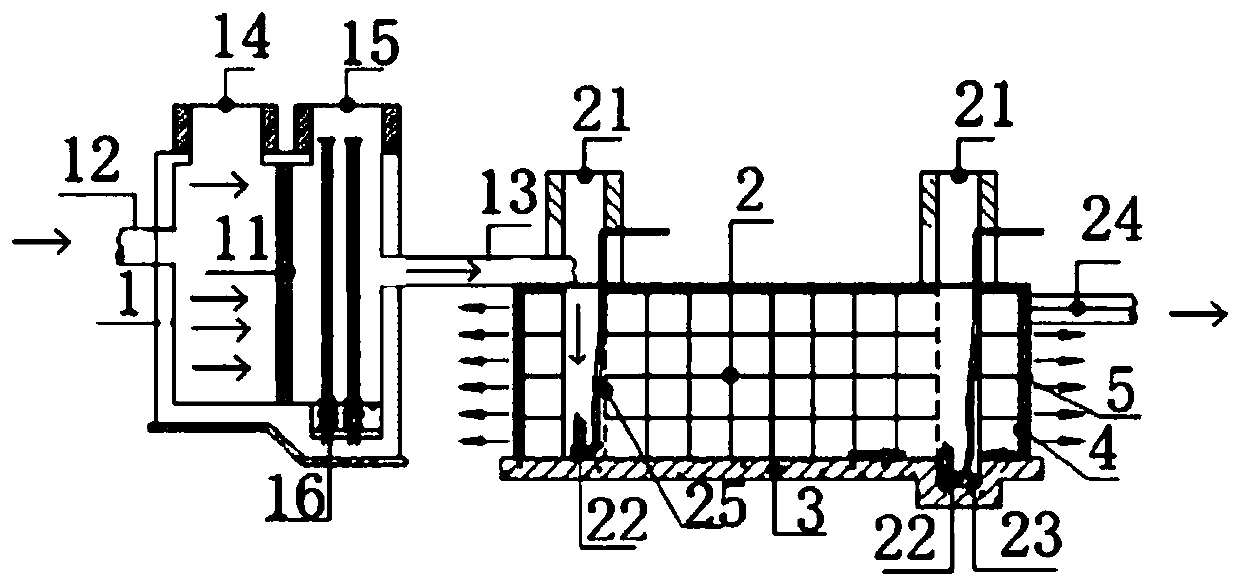

Rainwater collecting pool and construction method thereof

A rainwater collection and construction method technology, applied in chemical instruments and methods, water supply devices, waterway systems, etc., can solve the problems of no secondary use, easy leakage, rough concrete structure, etc., to save tap water resources, reduce air pollution, the effect of important environmental values

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

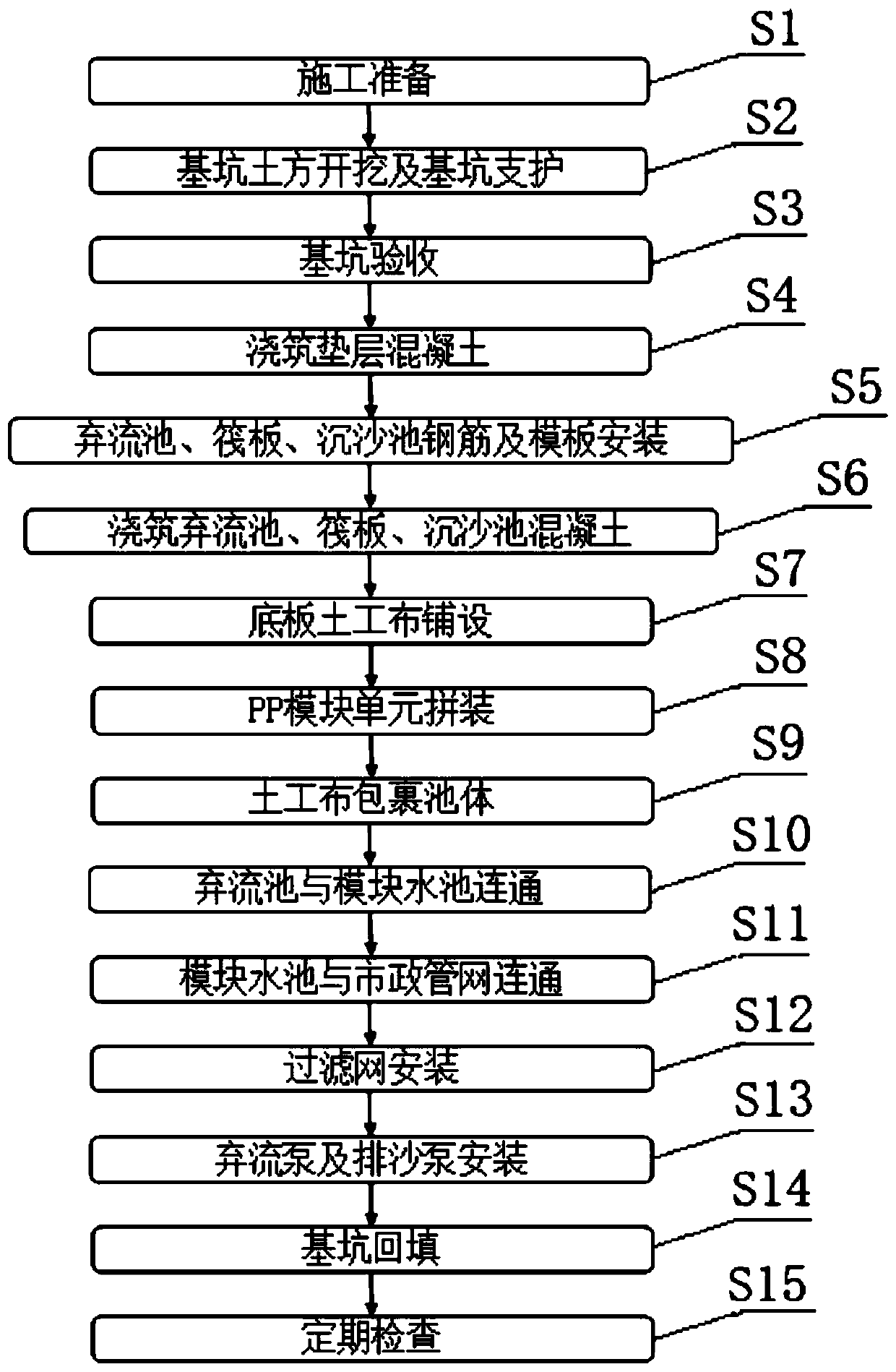

[0090] This construction method is suitable for rainwater collection and utilization in residential quarters, industrial parks, squares and factory areas.

[0091] 1. Construction preparation

[0092] 1. Necessary construction preparations are required before construction. The construction personnel must carefully familiarize themselves with the drawings before construction, accurately locate the position of the pool, and release the foundation pit excavation line, excavators, muck trucks and other equipment and PP modules and other materials preparation Finish;

[0093] 2. According to the "Geological Survey Report", conduct a detailed survey of the construction site, and be familiar with the surrounding underground trenches and adjacent buildings;

[0094] 3. Do a good job of setting up the site fence and the drainage ditches on both sides of the road in the construction site to prevent water accumulation in the site and ensure the smooth flow of construction machinery road...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com