Treatment solution for copper residue on surface of dart fixture

A treatment liquid and fixture technology, which is applied in the field of metal surface treatment, can solve the problems of health hazards for operators, unstable properties of concentrated nitric acid, and easy volatility, etc., to improve reaction stability, increase the amount of dissolved copper in the solution, and improve the surface active effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

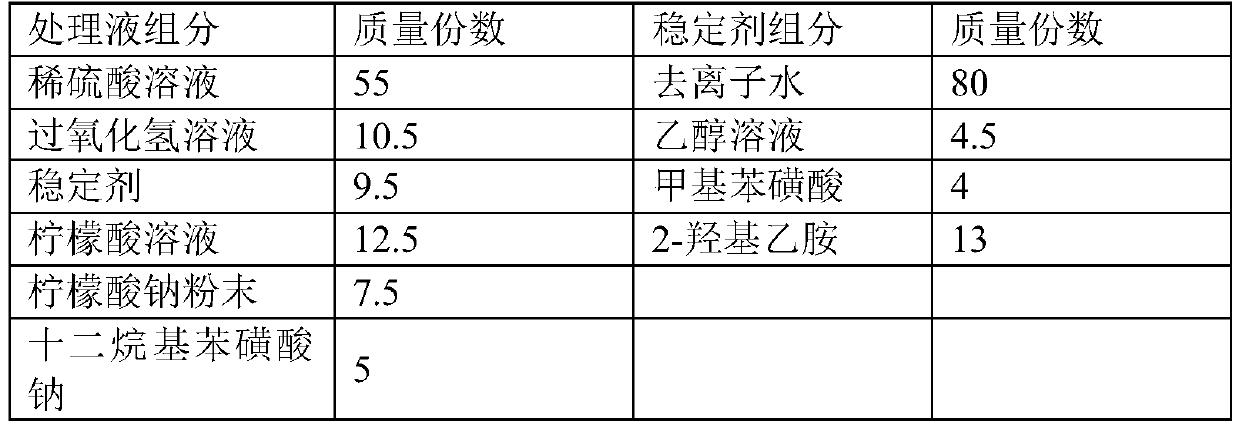

[0026] Embodiment 1, a copper treatment solution attached to the surface of a flying target fixture, includes the following components.

[0027]

Embodiment 2

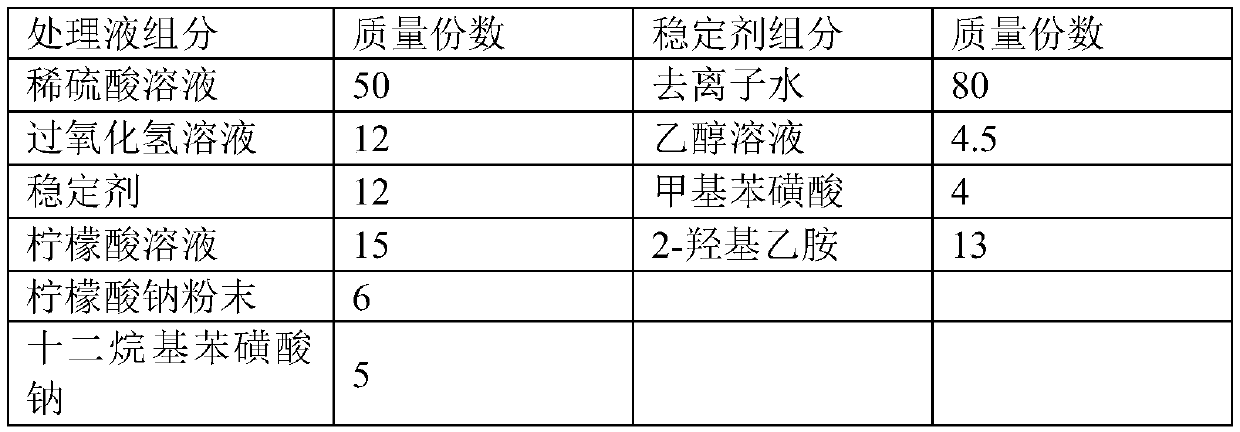

[0028] Embodiment 2, a copper treatment solution attached to the surface of a flying target fixture, includes the following components.

[0029]

Embodiment 3

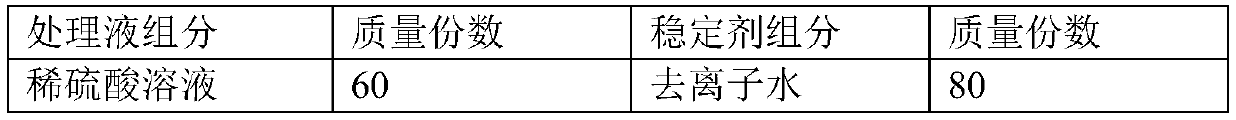

[0030] Embodiment 3, a copper treatment solution attached to the surface of a flying target fixture, includes the following components.

[0031]

[0032]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com