Concrete super plasticizer and preparation method thereof

A superplasticizer and concrete technology, applied in the field of superplasticizer with narrow molecular weight distribution and its preparation, can solve the problems of high viscosity, high dosage, poor dispersion performance of high-strength and ultra-high-strength concrete, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

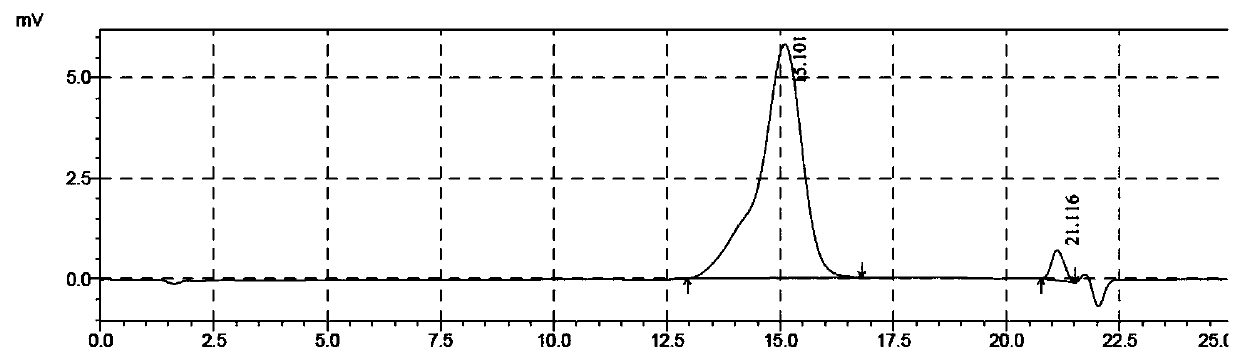

Image

Examples

Embodiment 1

[0100] (1) Remove water and oxygen from the reactor, add 0.414 parts of B1 and 0.748 parts of potassium tert-butoxide to the reactor under the protection of an inert (nitrogen) atmosphere, adjust the reactor to 100°C, and gradually and evenly add 114.12 parts of D1, the intermediate polymer was obtained after stirring for 24 hours;

[0101] (2) Add 250 parts of G1 to another reactor, adjust the reactor to 60°C, add 1.012 parts of triethylamine, 40.3 parts of I1, 62.21 parts of K1 and the intermediate polymer obtained in step (1), and stir After 24 hours of reaction, the volatile small molecules were removed in vacuo to obtain an intermediate mixture;

[0102] (3) Add 273.3 parts of H3 to the third reactor, adjust the reactor to 100°C, add 7.41 parts of p-toluenesulfonic acid and the intermediate mixture obtained in step (2) to it, stir and dehydrate under vacuum at 100°C for 24h, After the reaction, the volatile small molecules were removed in vacuum, and the reactor was retu...

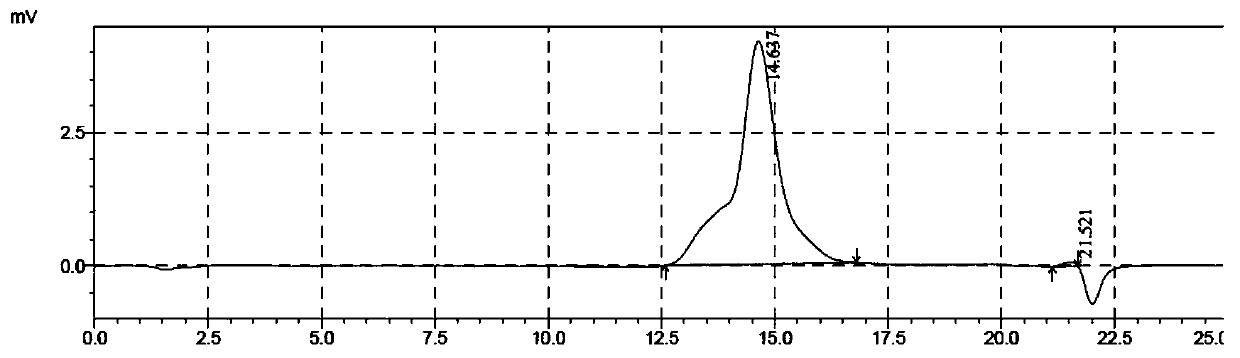

Embodiment 2

[0104] (1) Remove water and oxygen from the reactor, add 128.13 parts of dimethyl sulfoxide to the reactor under the protection of an inert (nitrogen) atmosphere, then add 9.265 parts of B2 and 0.15 parts of sodium hydride to it, and adjust the reactor to 120 ° C 128.13 parts of D2 were gradually and evenly added to it within 1 hour, and the intermediate polymer was obtained after stirring for 2 hours;

[0105] (2) Add 583.6 parts of G2 to another reactor, adjust the reactor to 20°C, add 2.623 parts of triphenylphosphine, 161 parts of I2, 26.73 parts of K2 and the intermediate polymer obtained in step (1) , After stirring for 6 hours, the volatile small molecules were removed in vacuum, and the reactor was returned to normal pressure and room temperature to obtain a superplasticizer sample PCE-ND02, with a weight average molecular weight of 6.4kDa and a PDI of 1.26.

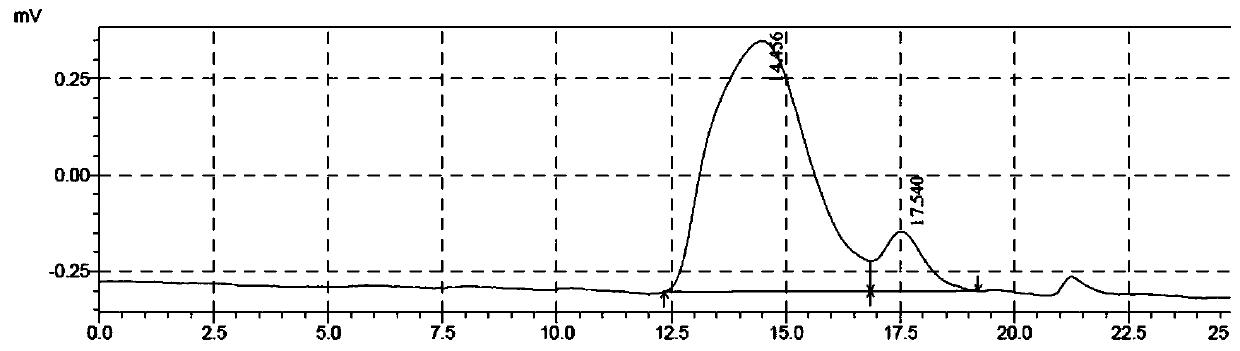

Embodiment 3

[0107] (1) The reactor is dewatered and deoxygenated, and 426.45 parts of N-methylpyrrolidone are added to the reactor under the protection of an inert (nitrogen) atmosphere, then 0.333 parts of sodium hydroxide and 4.658 parts of B3 are added thereto, and the reactor is adjusted to 150°C, gradually and uniformly add 142.15 parts of D3 to it within 3 hours, stir and react for 8 hours to obtain an intermediate polymer;

[0108] (2) Add 284.6 parts of G3 to another reactor, adjust the reactor to 0°C, add 0.32 parts of tri-n-propylphosphine, 131.02 parts of I3, 21.33 parts of K1 and the intermediate polymerization obtained in step (1) After stirring and reacting for 12 hours, the volatile small molecules were removed in vacuum, and the reactor was returned to normal pressure and room temperature to obtain a superplasticizer sample PCE-ND03 with a weight average molecular weight of 21.0kDa and a PDI of 1.29.

PUM

| Property | Measurement | Unit |

|---|---|---|

| number average molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com