Method for treating stainless steel acid-mixed wastewater

A treatment method and stainless steel technology, applied in the field of AGV vehicles, can solve the problems of high salt content in wastewater, large consumption of chemicals, high cost of denitrification, etc., and achieve high economic and environmental benefits, reduce treatment costs, and reduce fluorination. Effects of calcium sludge and iron hydroxide sludge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

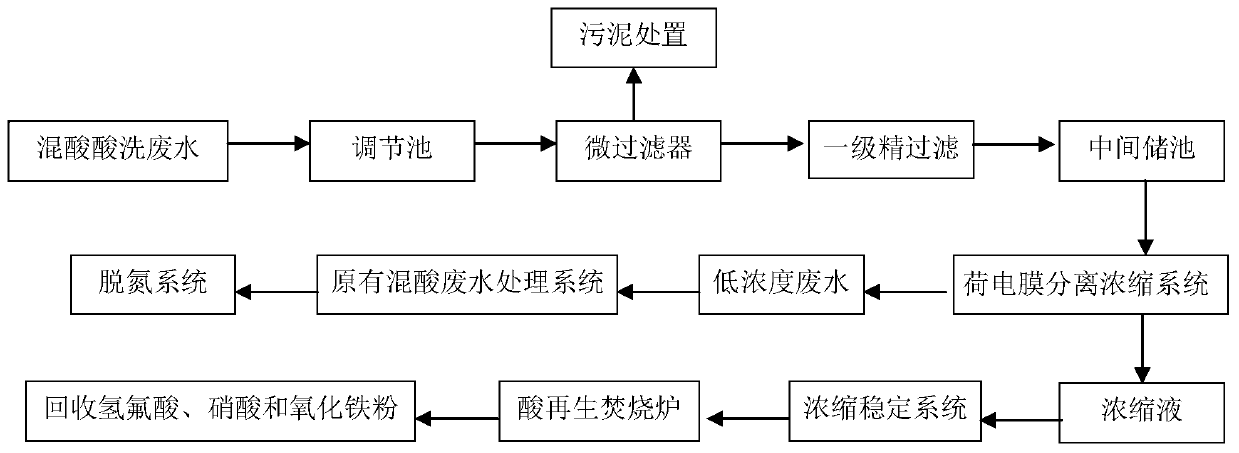

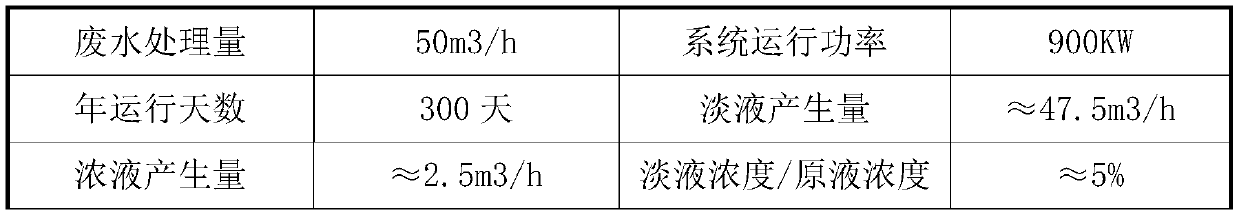

[0032] Such as figure 1 As shown, the present embodiment provides a kind of treatment method of stainless steel mixed acid wastewater, and described method comprises the following steps:

[0033] Step 1: Carry out pretreatment, filter the wastewater through a fully automatic microfilter to remove particles; since mixed acid wastewater contains a large amount of solid impurities and suspended solids, first pass through a fully automatic microfilter to filter out particles larger than 1 μm; After the filtration is saturated, the fully automatic micro-filter will automatically recoil to discharge the filtered sludge. After microfiltration, the waste water passes through a fine filtration system with a pore size of 1 μ to remove all remaining impurities, so that the waste water meets the liquid inlet requirements of the charged membrane reaction equipment.

[0034] In step 2, the pretreated wastewater is separated and concentrated by a charged membrane, so that the acid radicals...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com