Carbon separation reactor and carbon separation method and treatment method of fly ash

A reactor and reaction technology, applied in the direction of silica, silicon oxide, etc., can solve problems such as the inability to apply carbon pipes to prevent and remove blockage, crystallization and sediment blockage of the outlet, and the blockage of the feeding outlet, etc., and the frequency is convenient Adjustable, improved product quality, and timely blockage removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

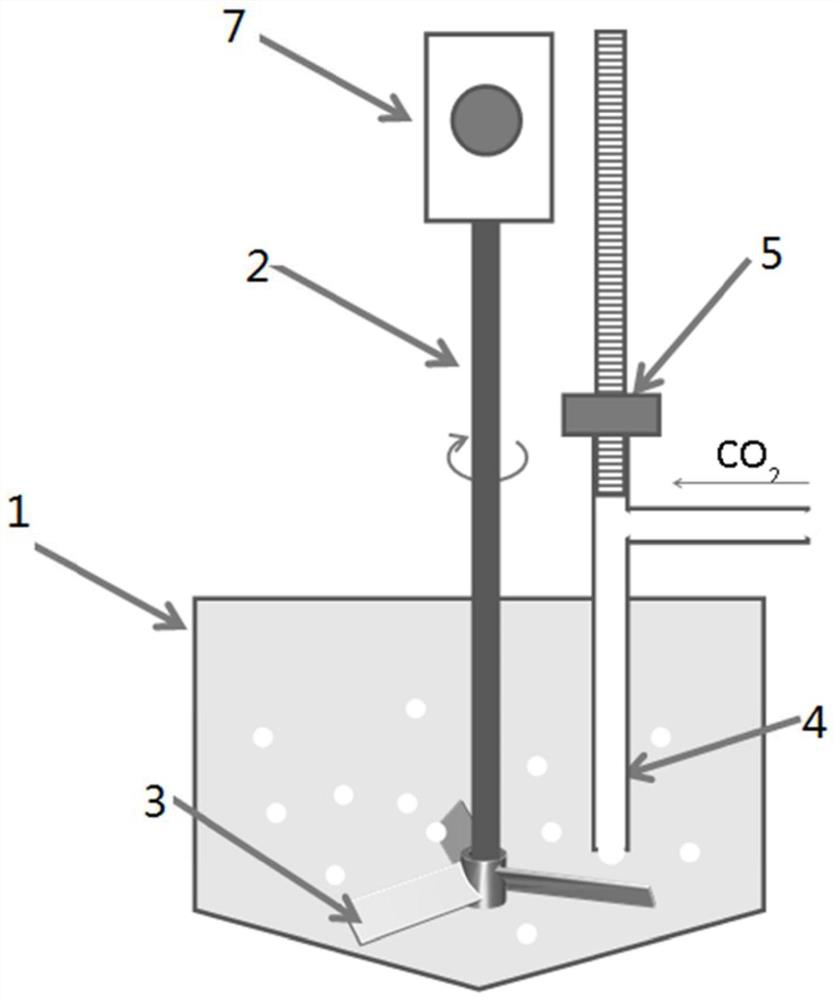

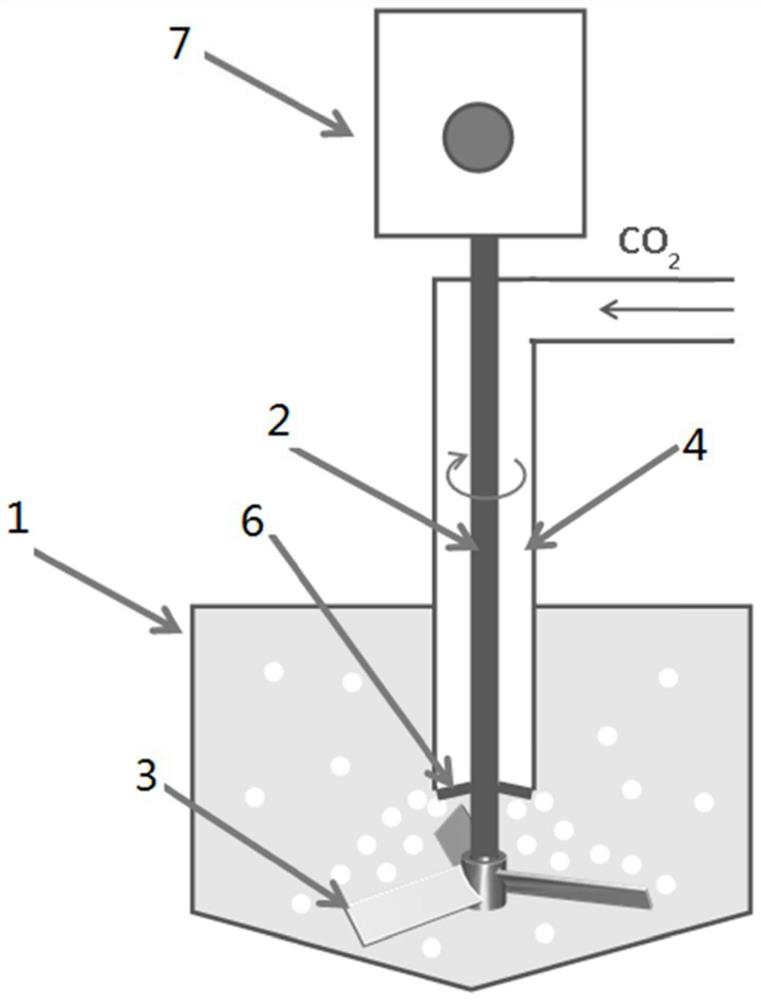

[0053] According to an embodiment of the present invention, the stirring device includes: a stirring motor, a stirring shaft and a stirring paddle, wherein, preferably, the stirring shaft communicates with the main body of the carbon reactor through the carbon dioxide inlet pipe, so The stirring motor is used to drive the stirring shaft to rotate.

[0054] According to the solution of the present invention, the stirring blade and the blockage removal scraper share the stirring shaft. In the specific use process, the minimum stirring speed can be set according to the mixing and stirring effect of the carbon slurry, for example, 30-150rpm. At the same time, according to the blockage of the carbon dioxide inlet pipe and the condition of the equipment, a large stirring speed can be used to clear the blockage. Namely, in the reactor of the present invention, at a low stirring speed, the silica solids adhered to the carbon dioxide inlet pipe due to the carbon reaction can be effect...

preparation Embodiment 1

[0091] A kind of high aluminum fly ash, the chemical composition is shown in Table 1.

[0092] Chemical composition analysis (percentage by weight) of table 1 high aluminum fly ash

[0093] SiO 2

[0094] According to the molar ratio of sodium hydroxide and silicon dioxide being 2.0, sodium hydroxide was weighed, and an alkali solution with a mass concentration of 10% was prepared. Mix with fly ash in Table 1, stir and react at 95°C for 60 minutes, and filter to obtain water glass.

preparation Embodiment 2

[0096] A high-aluminum fly ash residue from acid extraction of aluminum, the chemical composition of which is shown in Table 2.

[0097] Chemical composition analysis (weight percent) of the aluminum extraction residue of table 2 acid method

[0098] SiO 2

[0099] According to the molar ratio of sodium hydroxide and silicon dioxide being 1.3, measure sodium hydroxide, and prepare an alkali solution with a mass concentration of 30%. Mix it with the fly ash in Table 2, stir and react at 135°C for 60 minutes, cool and filter to obtain water glass.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com