Low-quality and low-concentration protection extraction process for graphite squama

An extraction process and technology of graphite flakes, applied in the field of low-quality and low-concentration protection extraction process of graphite flakes, can solve the problems of high energy consumption, limited purification purity, complex process flow, etc., achieve high content, solve screening and classification difficulties, and improve quality Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

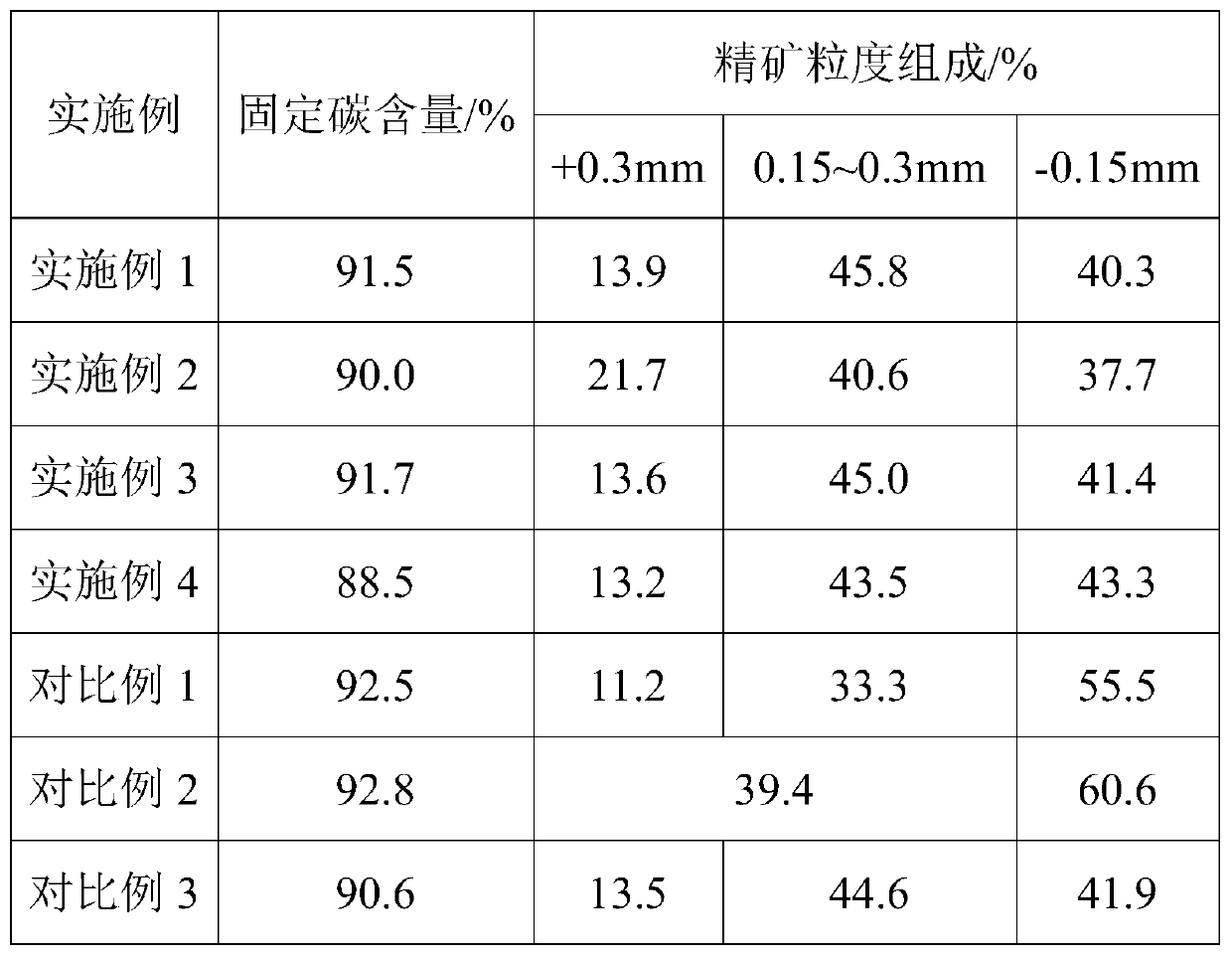

Examples

Embodiment 1

[0047] 1) Crushing: A crystalline graphite raw ore with a carbon content of 4.58% in Luobei is crushed by a jaw crusher, and then enters a roller press for closed-circuit crushing. The crushed particle size is 1-2 mm, and the materials that do not meet the particle size requirements are returned to the roller press. ;

[0048] 2) Wet grinding: the pulverized material enters the rod mill for wet grinding, and the content of the particle size above 0.15mm is 40%;

[0049] 3) Rough separation: the wet grinding material enters the flotation machine for rough separation under the concentration of ore pulp 10%, kerosene 50g / t, and No. Mine 1; the re-election overflow is coarse concentrate, and the bottom flow is merged into the middle ore 1; the foam of the flotation machine is intermittently washed with spray water during the flotation process;

[0050] 4) Regrinding: the coarse concentrate enters the rod mill for regrinding, and the content of the particle size above 0.15mm is 30...

Embodiment 2

[0053] 1) Crushing: A crystalline graphite raw ore with a carbon content of 6.02% in Madagascar is crushed by a jaw crusher, and then enters a roller press for closed-circuit crushing. The crushed particle size is 1-2mm, and the materials that do not meet the particle size requirements are returned to the roller press;

[0054] 2) Wet grinding: the pulverized material enters the rod mill for wet grinding, and the content of the particle size above 0.15mm is 50%;

[0055] 3) Rough separation: The wet grinding material enters the flotation machine for rough separation under the concentration of ore pulp 5%, kerosene 20g / t, No. 2 oil 100g / t; Mine 1; the re-election overflow is coarse concentrate, and the bottom flow is merged into the middle ore 1; the foam of the flotation machine is intermittently washed with spray water during the flotation process;

[0056] 4) Regrinding: the coarse concentrate enters the rod mill for regrinding, and the content of the particle size above 0.1...

Embodiment 3

[0059] 1) Crushing: A crystalline graphite raw ore with a carbon content of 4.58% in Luobei is crushed by a jaw crusher, and then enters a roller press for closed-circuit crushing. The crushed particle size is 1-2mm, and the materials that do not meet the particle size requirements are returned to the roller press. ;

[0060] 2) Wet grinding: the pulverized material enters the rod mill for wet grinding, and the content of the particle size above 0.15mm is 50%;

[0061] 3) Rough separation: the wet grinding material enters the flotation machine for rough separation under the conditions of pulp concentration 8%, kerosene 50g / t, No. 2 oil 50g / t; Mine 1; the re-election overflow is coarse concentrate, and the bottom flow is merged into the middle ore 1; the foam of the flotation machine is intermittently washed with spray water during the flotation process;

[0062] 4) Regrinding: the coarse concentrate enters the rod mill for regrinding, and the content of the particle size abov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com