Pay-off equipment for cable processing

A kind of equipment and cable technology, which is applied in the field of pay-off equipment for cable processing, can solve the problems of fixed conductor disc, broken conductor, bulky conductor disc, etc., and achieve the effect of reducing breakage and facilitating disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0028] see Figure 1-Figure 10 , the specific embodiments of the present invention are as follows:

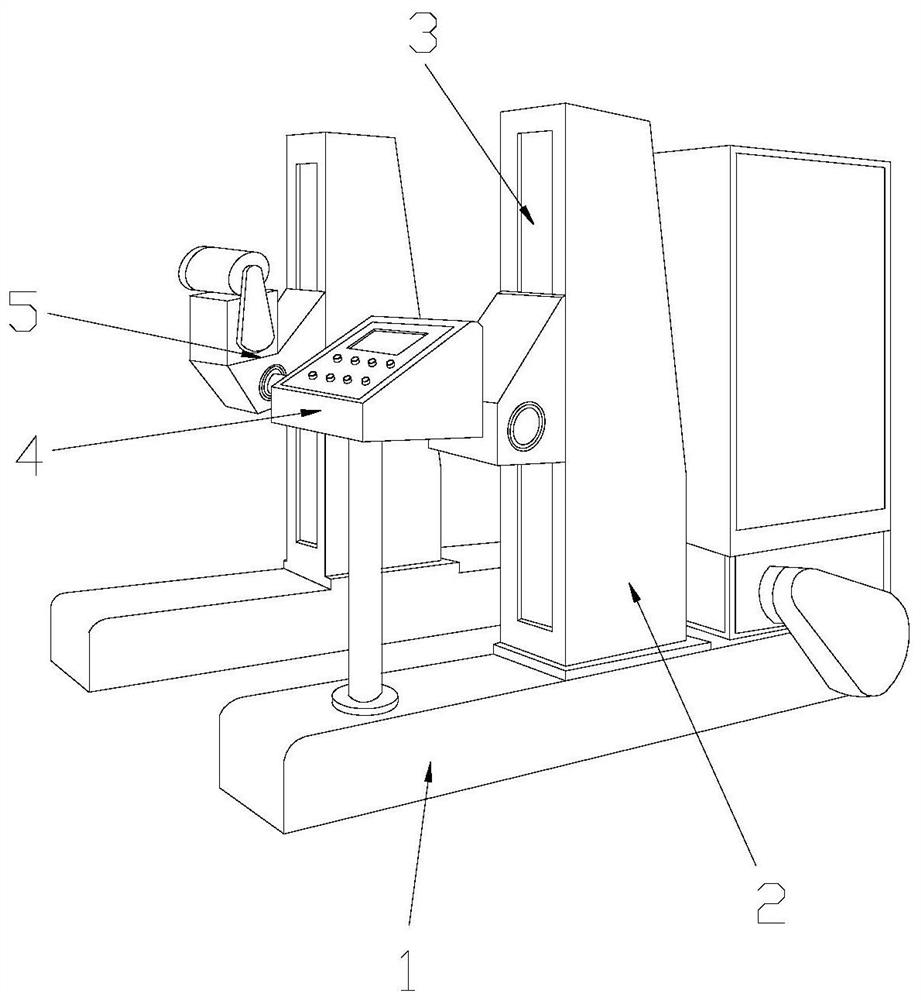

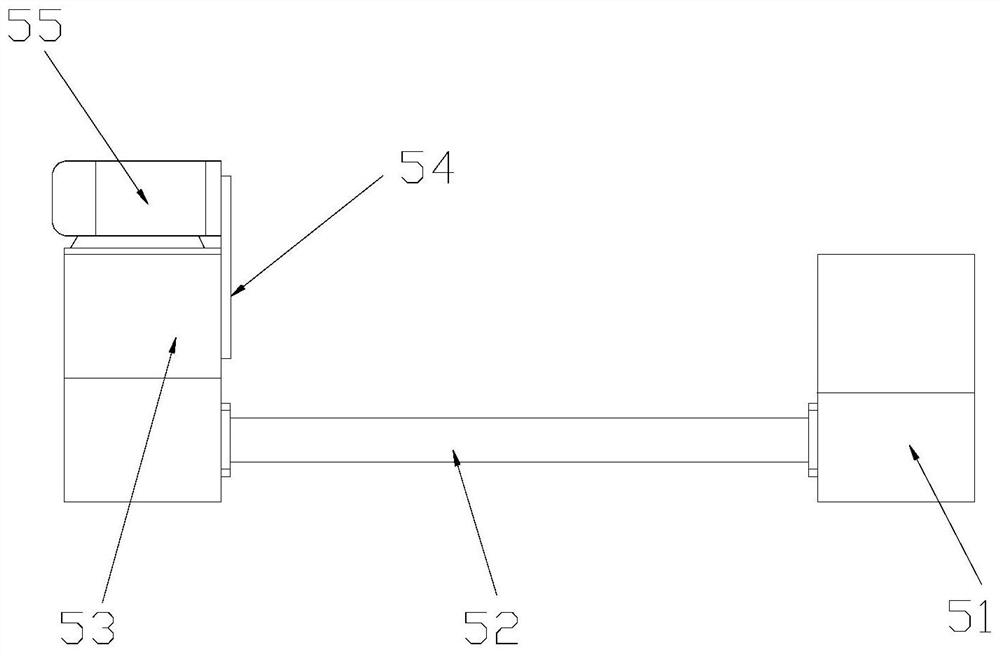

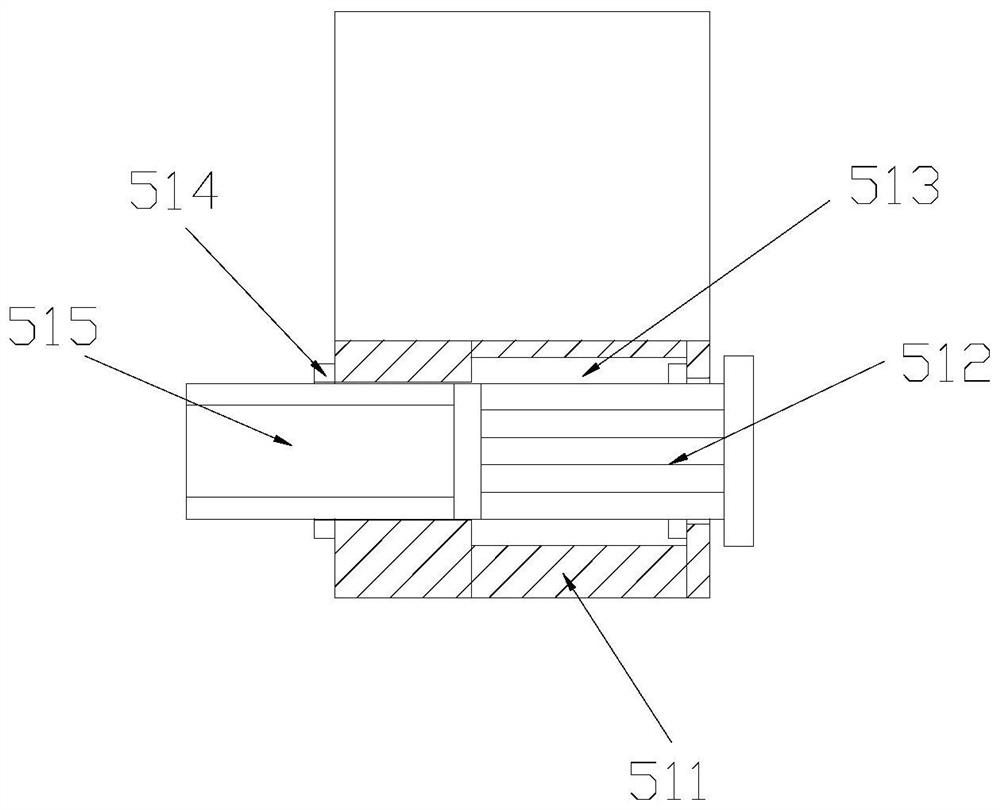

[0029] Its structure includes a load-bearing beam 1, a support beam 2, a lifting rail 3, a control box 4, and a wire release device 5. The support beam 2 is vertically installed on the upper end of the load-bearing beam 1 and welded, and the lifting rail 3 is embedded and installed on the support beam. 2, the control box 4 is arranged above the load-bearing beam 1, and the wire-releasing device 5 is installed on the front end of the supporting beam 2 and is flexibly connected with the lifting rail 3; the wire-releasing device 5 includes a driven disassembly structure 51, a wire-releasing structure 52, a transmission structure 53, a transmission belt 54, and a motor 55. The left side of the driven dismounting structure 51 is equipped with a pay-off structure 52 and adopts a flexible connection. The motor 55 is connected with the transmission structure 53 through the transmissio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com