Method for realizing co-curing of L-shaped reinforcing rib and C-shaped frame-structure composite part through high-strength soft tool

A high-strength, ribbed technology, applied in the field of high-performance carbon fiber composite structural parts manufacturing, can solve the problems of material stress accumulation, increased manufacturing cycle, and reduced production efficiency, and achieve uniform and accurate pressure, high manufacturing success rate, and short production cycle. short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A kind of high-strength soft tooling realizes the method for co-curing of L-shaped reinforcing ribs and C-shaped frame structure composite parts, comprising the following steps:

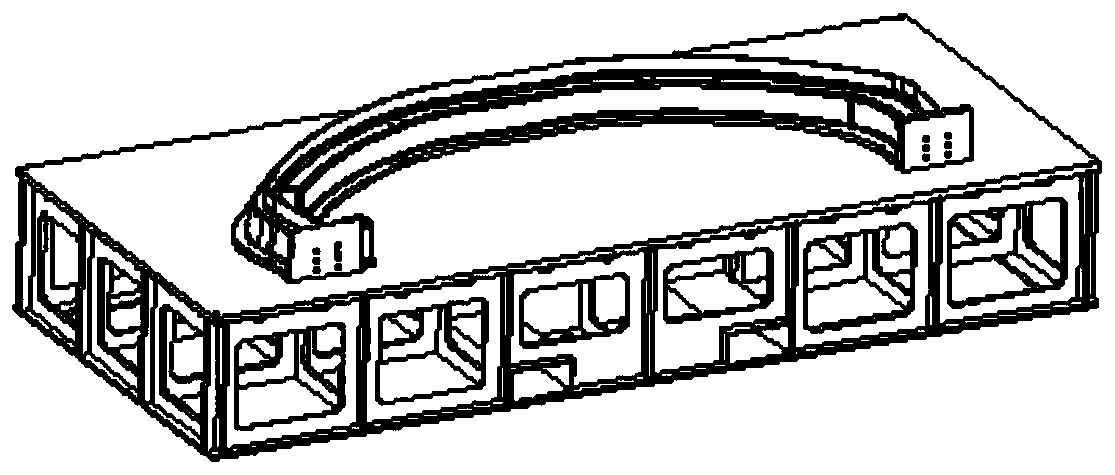

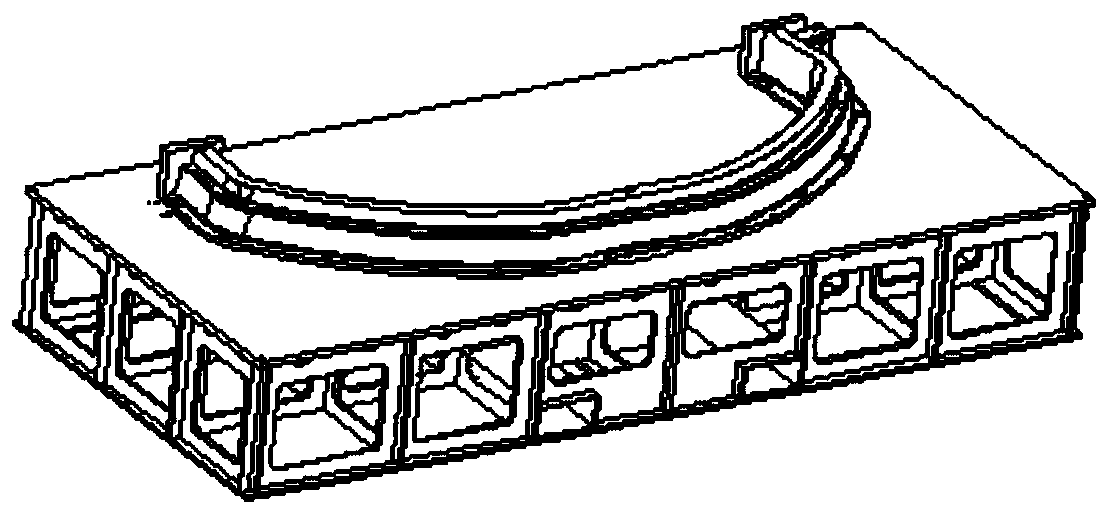

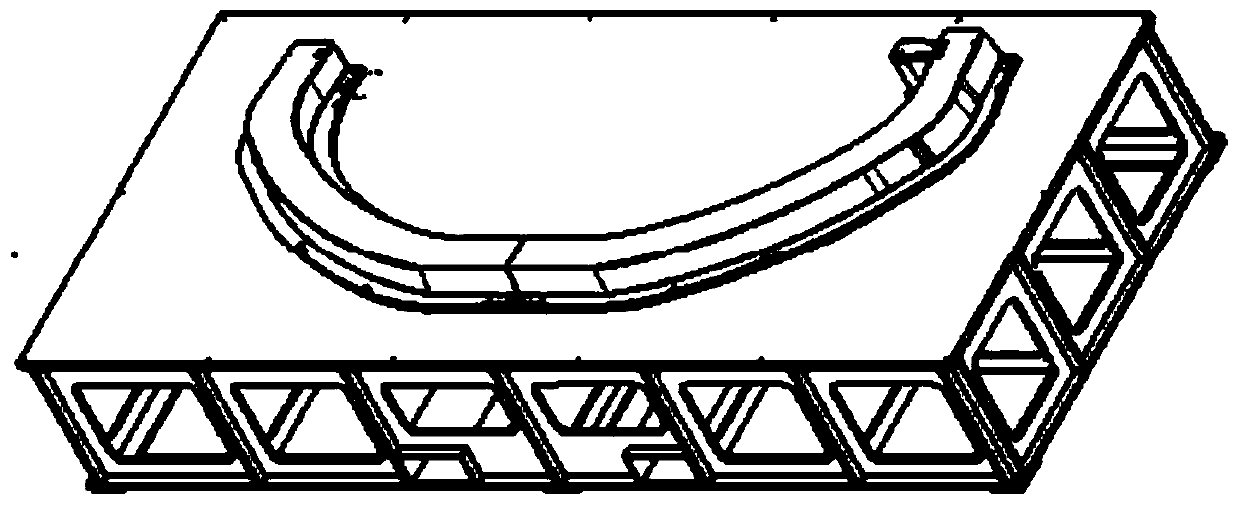

[0037] Step 1: Mold making, through the method of mechanical manufacturing, process two sets of metal forming molds with the same size as the left and right sides of the composite material parts, such as figure 1 and 2 The left metal mold and the right metal mold shown and as image 3 A set of C-shaped metal forming molds completely consistent with the inner surface of the C-shaped web of the workpiece is shown, and three sets of metal mold ends are equipped with corresponding drilling templates for drilling after curing;

[0038] Step 2: Lay a layer of rubber on the left and right metal forming molds respectively. After the first layer of rubber is paved, continue to pave two layers of carbon fiber prepreg or glass fiber prepreg on the rubber layer as a reinforcement layer;

[0039] Step 3:...

Embodiment 2

[0043] A kind of high-strength soft tooling realizes the method for co-curing of L-shaped reinforcing ribs and C-shaped frame structure composite parts, comprising the following steps:

[0044]Step 1: Mold making, through mechanical manufacturing, process two sets of metal forming molds with the same size as the left and right sides of the composite material parts, such as figure 1 and 2 The left metal mold and the right metal mold shown and as image 3 A set of C-shaped metal forming molds completely consistent with the inner surface of the C-shaped web of the workpiece is shown, and three sets of metal mold ends are equipped with corresponding drilling templates for drilling after curing;

[0045] Step 2: Lay a layer of rubber on the left and right metal forming molds respectively. After the first layer of rubber is paved, continue to pave 10 layers of carbon fiber prepreg or glass fiber prepreg on the rubber layer as a reinforcement layer;

[0046] Step 3: Seal the vacuum...

Embodiment 3

[0050] A kind of high-strength soft tooling realizes the method for co-curing of L-shaped reinforcing ribs and C-shaped frame structure composite parts, comprising the following steps:

[0051] Step 1: Mold making, through mechanical manufacturing, process two sets of metal forming molds with the same size as the left and right sides of the composite material parts, such as figure 1 and 2 The left metal mold and the right metal mold shown and as image 3 A set of C-shaped metal forming molds completely consistent with the inner surface of the C-shaped web of the workpiece is shown, and three sets of metal mold ends are equipped with corresponding drilling templates for drilling after curing;

[0052] Step 2: Lay a layer of rubber on the left and right metal forming molds respectively. After the first layer of rubber is paved, continue to pave 5 layers of carbon fiber prepreg or glass fiber prepreg on the rubber layer as a reinforcement layer;

[0053] Step 3: Seal the vacuum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com