A Welding Process of Super Duplex Stainless Steel and Super Austenitic Stainless Steel

A technology of austenitic stainless steel and duplex stainless steel, applied in welding equipment, welding medium, welding equipment, etc., can solve problems such as the decline of mechanical properties of welded joints, the growth of ferrite grains, and the lack of chromium in the intergranular, etc., to achieve Excellent resistance to pitting corrosion and intergranular corrosion, excellent resistance to stress corrosion cracking, and the effect of improving performance and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

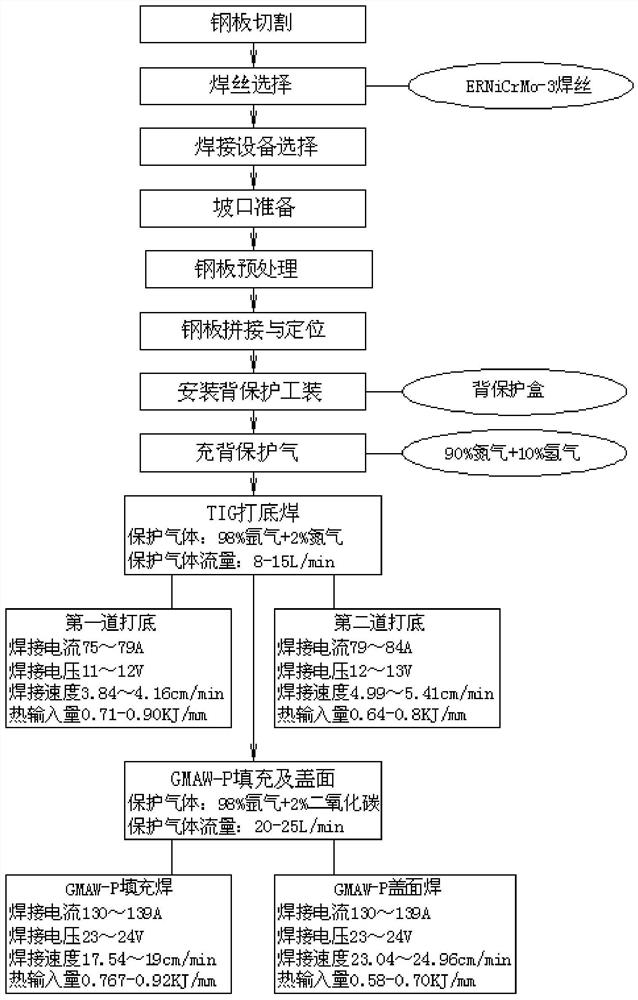

[0043] Such as Figures 1 to 2 Shown is an embodiment of the welding process of a super duplex stainless steel and super austenitic stainless steel of the present invention, the super duplex stainless steel is 2507 super duplex stainless steel, and the super austenitic stainless steel is 254SMo super austenitic stainless steel body stainless steel, the welding process comprises the following process steps:

[0044] (1) Steel plate cutting: 2507 and 254SMo stainless steel plates are used, which are cut and shaped according to the design requirements;

[0045] (2) Selection of welding wire: use a welding wire with a diameter of φ2.4mm as the TIG welding wire for backing, and use a welding wire with a diameter of φ1.2mm as the GMAW-P welding wire for filling and covering; wherein, the φ2.4mm The welding wire and the welding wire with a diameter of φ1.2mm are both AWSA5.14: ERNiCrMo-3 welding wire;

[0046] (3) Selection of welding equipment: TIG welding machine is used for the ...

Embodiment 2

[0069] On the basis of embodiment 1, the welding process parameters of TIG bottom welding and GMAW-P filling and cover welding are further specified as follows:

[0070] Among them, the welding process parameters of the TIG backing are: the polarity of the power supply is direct current, the tungsten electrode type of the TIG welding torch is cerium tungsten electrode WCe-20, and the diameter is φ2.4mm; the nozzle of the TIG welding torch should use a nozzle with an inner diameter of 16mm. The shielding gas is 98% volume percentage of argon + 2% volume percentage of nitrogen, and the flow rate of the shielding gas is 12L / min; the welding current of the first backing welding is 75-79A, the voltage is 11-12V, and the welding speed is 4cm / min. heat input

[0071] 0.71-0.90KJ / mm; the welding current of the second bottom welding is 82A, the welding voltage is 12-13V, the welding speed is 5cm / min, and the heat input is 0.64-0.8KJ / mm;

[0072] Among them, the welding process paramet...

Embodiment 3

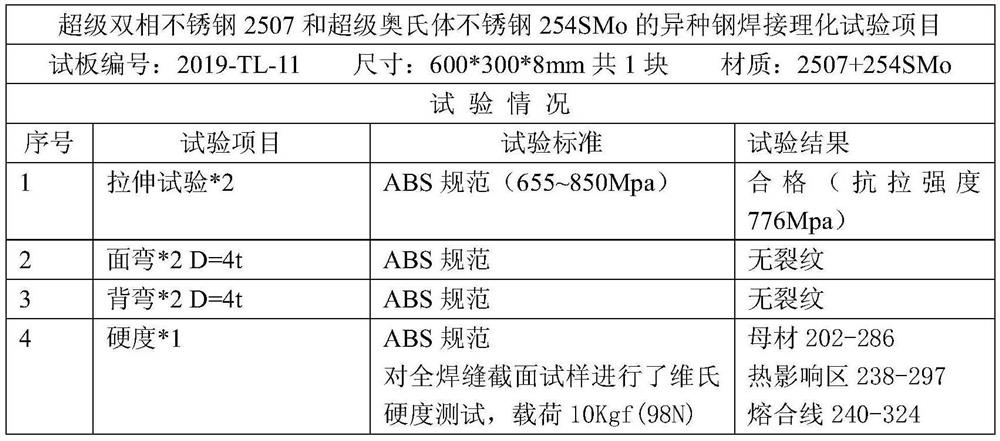

[0074] Adopt the welding process of embodiment 1 and embodiment 2, carry out super duplex stainless steel 2507 and super austenitic stainless steel to be the dissimilar steel welding test of 254SMo, the welding test plate is processed according to the sample size requirement of corresponding detection standard, with American ship Classification society (ABS) material and welding specifications are used as guiding documents, and the following items are tested, as shown in the table below:

[0075]

[0076]

[0077]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap