A bean flour milling device

A milling device and bean technology, applied in grain processing, etc., can solve problems such as low efficiency, nutrient loss, and inability to guarantee the sieving effect, and achieve the effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

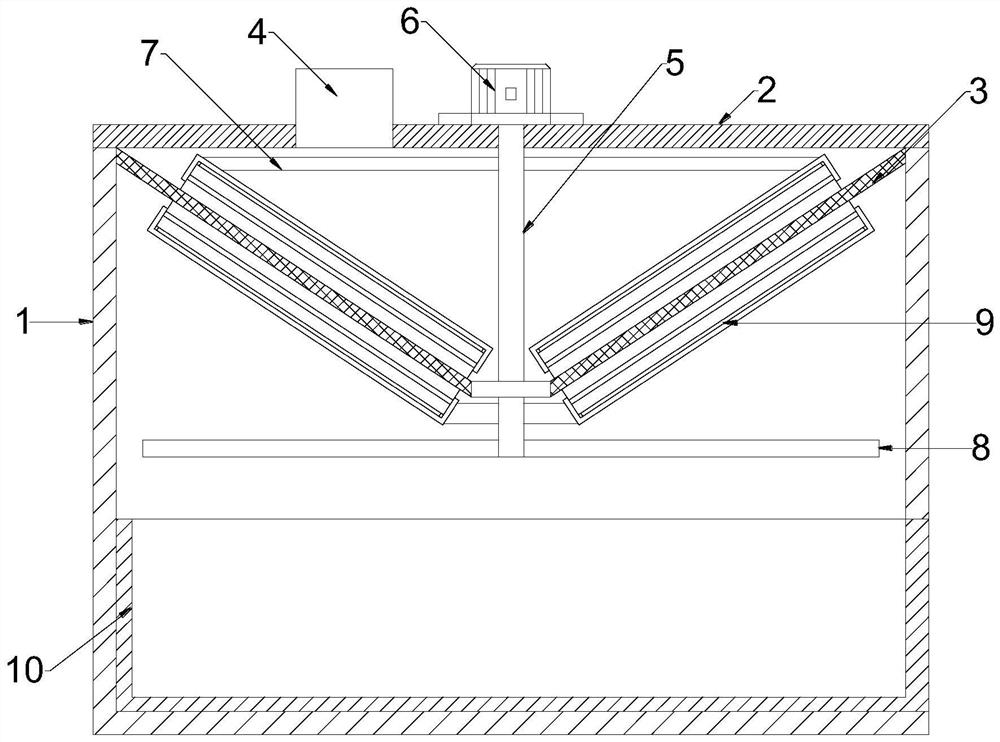

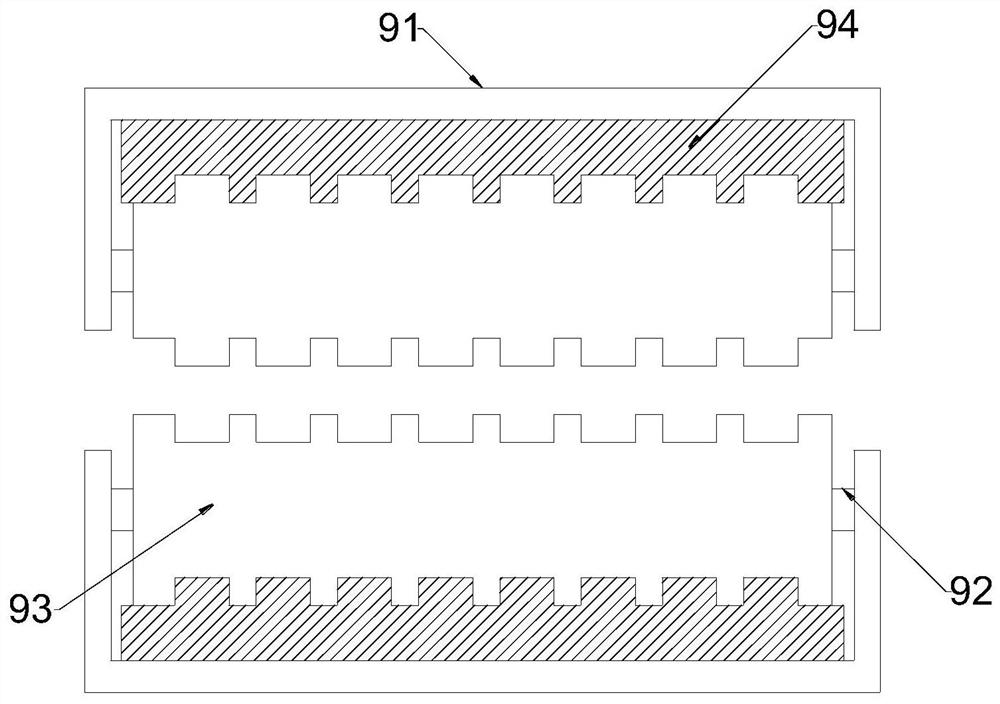

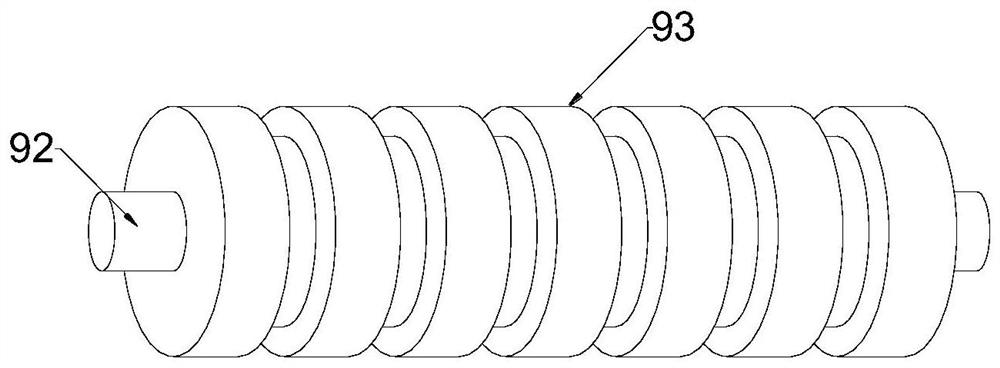

[0022] see Figure 1~3 , in an embodiment of the present invention, a bean milling device includes a housing 1 and an upper cover 2, the upper cover 2 is assembled and fixed on the upper end of the housing 1 by riveting, and the inside of the housing 1 is welded, riveted Or the clamping mode is assembled with a filter screen 3, the upper cover 2 is penetrated with a feed pipe 4, and the upper cover 2 is also connected with a drive shaft 5 driven by a motor 6, and the drive shaft 5 is There are multiple groups of crushing rollers 9 for crushing materials, the crushing rollers 9 are arranged around the drive shaft 5, and the crushing rollers 9 include upper crushing parts respectively located on the upper and lower sides of the filter screen 3 and the lower support member, the upper rolling member and the lower support member are respectively connected to the drive shaft 5 for transmission through a cutting structure and a connecting rod.

[0023] One side of the bottom of the ...

Embodiment 2

[0028] see Figure 4 , in the embodiment of the present invention, a bean milling device, on the basis of embodiment 1, the cutting structure is located below the feed pipe 4, and includes multiple groups of blades 7 connected at equal angles and fixed on the periphery of the drive shaft 5 And the connecting ring 71 fixedly connected to the periphery of the end of the blade 7, the edge of the connecting ring 71 is connected and fixed with the upper rolling part. After the beans fall, the cutting structure can not only drive the upper rolling part to rotate, but also can feed the The beans falling in the pipe 4 are processed and cut, which is convenient for crushing and sieving, and effectively improves the processing efficiency.

[0029] The working principle of the present invention is: the beans are fed through the feed pipe 4, and after the beans fall, the starting motor 6 drives the drive shaft 5 to rotate, and the cutting structure rotates and cuts the material. The cutti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com