Catalyst and preparation method and use thereof

A catalyst and solvent technology, which is applied in the field of catalytic material preparation, can solve the problems of high preparation cost, insufficient efficiency of decomposing water to produce hydrogen, and scarce reserves of precious metal elements, etc., to achieve improved hydrogen production efficiency, improved catalytic utilization, and high photocatalytic water splitting active effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0082] The preparation method of catalyst comprises the following steps:

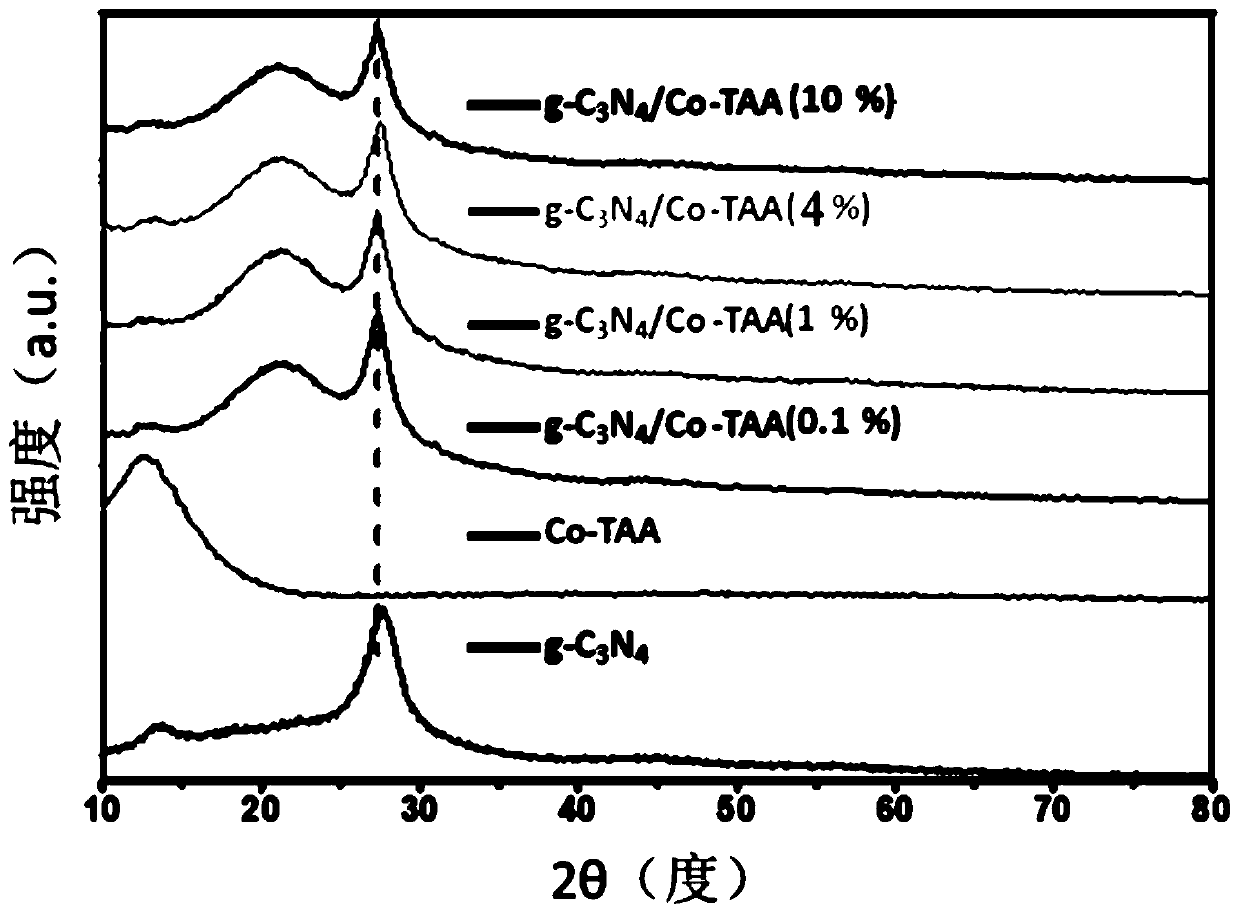

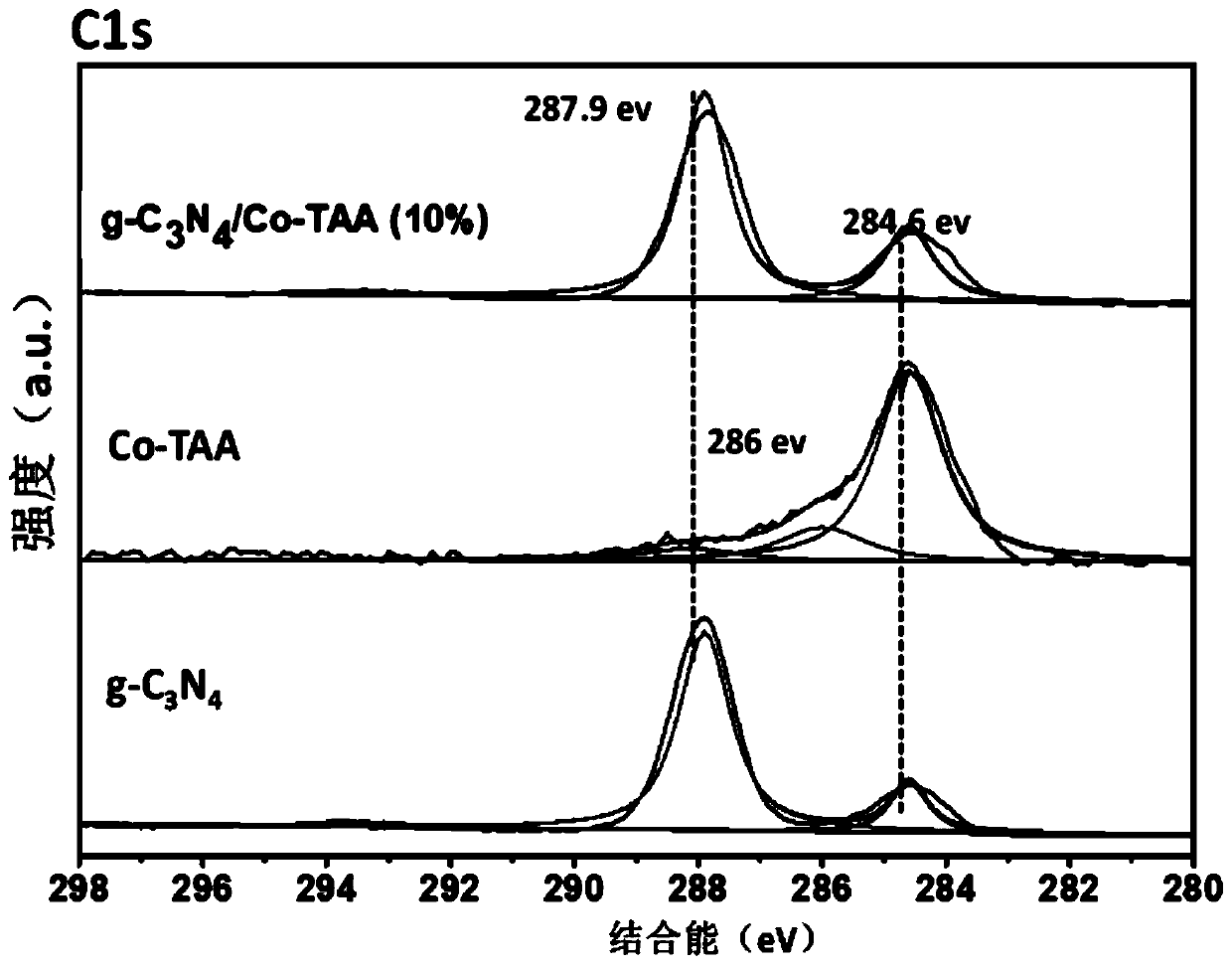

[0083] (1') 131.5mg CoCl 2 ·6H 2 0 and 4g TAA were dissolved in 50mL N,N-dimethylformamide, ultrasonically dispersed for 2min to obtain a precursor solution (Co-TAA); the concentration of cobalt source in the precursor solution was 11 μmol / mL;

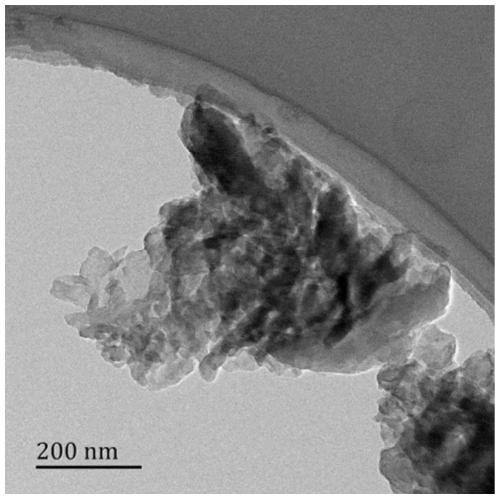

[0084] (2') 5 mg of graphitic carbon nitride (g-C 3 N 4 ) nanosheets are mixed with the solution of step (1'), ultrasonically treated at 25°C for 10min, centrifuged and washed with ethanol for 3 times (centrifugal speed is 12000rpm, time is 5min), and dried at 25°C to obtain the catalyst; the mixed The volume ratio of the graphite phase carbon nitride nanosheet mass to the solution of step (1') is 1mg / μL, and the Co in the mixture obtained by the mixing 2+ with g-C 3 N 4 The molar ratio is 0.1%, and the resulting catalyst is denoted as g-C 3 N 4 / Co-TAA (0.1%).

[0085] Wherein, the preparation method of described graphitic phase carbon nitride nanoplat...

Embodiment 2

[0089] Compared with Example 1 in this embodiment, the volume ratio of the mass of graphite-phase carbon nitride nanosheets mixed in step (2') to the solution in step (1') is 0.2 mg / μL; Co in the mixture 2+ with g-C 3 N 4 The mol ratio is 0.5%; Other conditions are identical with embodiment 1, and gained catalyst is recorded as g-C 3 N 4 / Co-TAA (0.5%).

Embodiment 3

[0091] Compared with Example 1 in this embodiment, the volume ratio of the mass of graphite-phase carbon nitride nanosheets mixed in step (2') to the solution in step (1') is 0.1 mg / μL; Co in the mixture 2+ with g-C 3 N 4 The mol ratio of is 1%; Other conditions are identical with embodiment 1, and gained catalyst is recorded as g-C 3 N 4 / Co-TAA (1%).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com