Variable branch modular permanent magnetic built-in outer rotor hub motor for electric vehicle

A technology of electric vehicles and wheel hub motors, applied in the field of motors, can solve the problems of high amplitude of back electromotive force induced by no-load in stator windings, lack of advantages in the production of modular rotors, and limit the range of motor speed adjustment, etc., to achieve enhanced magnetic concentration effect, The effect of widening the speed range and reducing performance requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] As a preferred embodiment of the present invention, with reference to the attached Figure 1-10 , this example discloses:

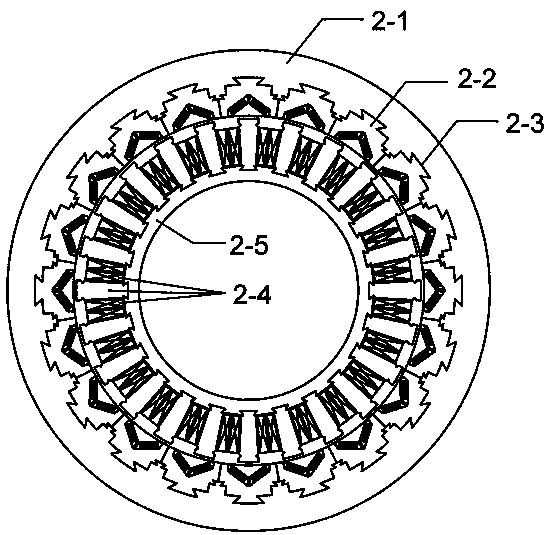

[0048] The variable branch modular permanent magnet built-in outer rotor hub motor 1 provided in this embodiment includes a stator and a rotor 1-1. The stator is located inside the motor and is composed of a stator core 1-2 and stator windings 1-3 and 1-4, and the stator core 1-2 is composed of Ns stator tooth modules 2-4 and a stator yoke 2-5 . The stator tooth module 2-4 includes a stator tooth 5-1 and a winding coil 5-2 wound on the stator tooth 5-1, which is made of laminated silicon steel sheets, and its bottom is designed as a dovetail structure 5-3; The winding coil 5-2 is formed by winding multiple turns of conductor wire. Since only one coil is wound on each stator tooth 5-1, the stator tooth module 2-4 can realize automatic winding and automatic assembly of the coil. The stator yoke 2-5 is an annular structure made of laminated silico...

Embodiment 2

[0053] As another preferred embodiment of the present invention, with reference to the attached Figure 1-10 , this embodiment provides a variable branch modular permanent magnet built-in outer rotor hub motor 1, the number of stator winding phases m=3, the number of each phase branch k=2, the number of sets of stator windings t=2, each set The number of parallel branches per phase of the stator winding n=1. figure 1 A functional block diagram of an in-wheel motor system provided by an embodiment of the present invention is shown, and the details are as follows:

[0054] The variable branch modular permanent magnet built-in outer rotor hub motor includes an outer rotor hub motor 1, a first set of AC-DC inverter 2, a second set of AC-DC inverter 3, a circuit switching controller 4, and an in-vehicle bus 5. Wherein, the outer rotor hub motor 1 includes: a rotor 1-1, a stator core 1-2, a first set of stator windings 1-3 and a second set of stator windings 1-4.

[0055] Now in c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com