External rotor permanent magnet motor

A permanent magnet motor and external rotor technology, which is applied to the rotor and related motors, and the fixed field of the external rotor permanent magnet motor, can solve the problem that the air gap magnetic density of the concentrated winding is large, the vibration and noise are large, and the cost of the magnetic steel increases. and other problems, to achieve the effect of high winding coefficient, improved performance and low torque ripple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

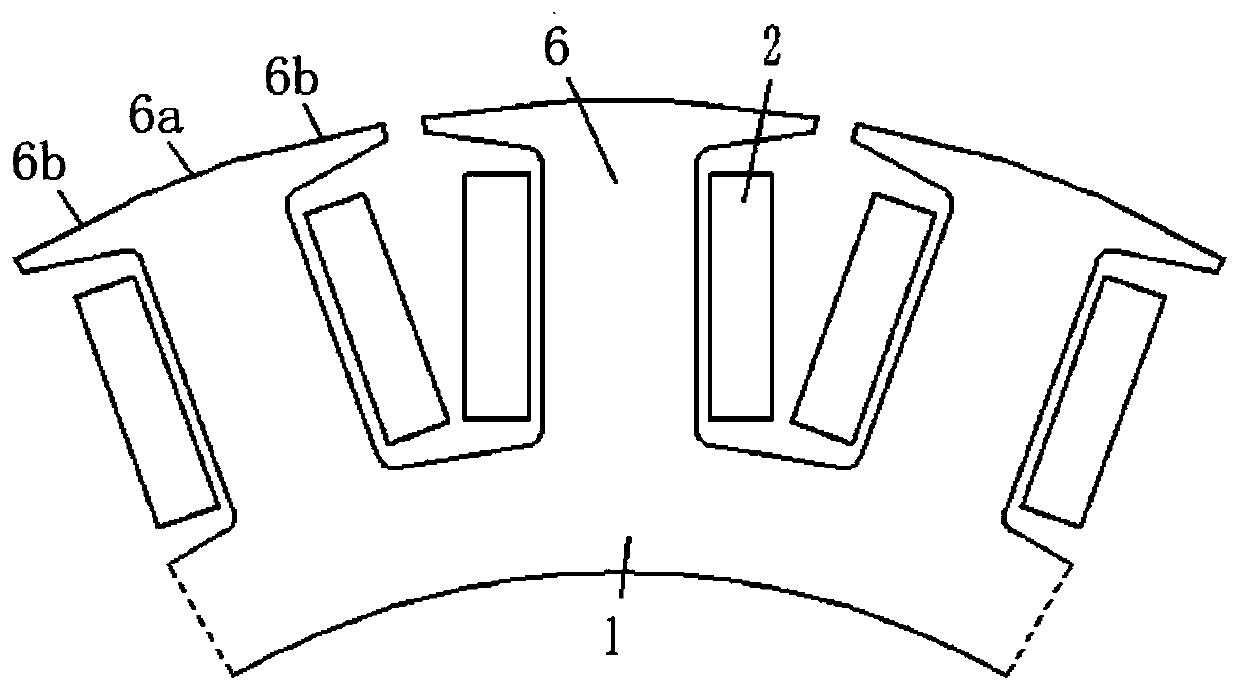

[0021] Embodiment 1: as figure 1 As shown, an outer rotor permanent magnet motor includes a stator and an outer rotor. The outer rotor includes a rotor core 3 and several rotor magnets 4 fixed inside the rotor core 3 . The stator includes a stator core 1 and a stator winding 2 embedded in the stator slot. The stator tooth 6 includes a tooth body 6a and tooth shoes 6b located on the left and right sides of the tooth body 6a. The top surfaces of the tooth body 6a and the tooth shoes 6b on the left and right sides form Segmented structure.

[0022] The relationship between the stator slot number Q and the outer rotor pole number 2P satisfies Q=2P±1 or Q=2P±2, where P is the number of rotor pole pairs. Setting the appropriate slot and pole coordination can increase the winding coefficient of the motor, increase the flux linkage of the motor, and improve the output capacity of the motor. The cross-section of the rotor magnetic steel 4 perpendicular to the motor shaft is an isosc...

Embodiment 2

[0026] Embodiment 2: The only difference from Embodiment 1 is that the top surfaces of the tooth shoes 6b on the left and right sides of a single stator tooth 6 are located on a regular polygonal structure, and the top surfaces of the tooth body 6a in the middle of the tooth shoes 6b on the left and right sides are circular arcs , the center of the arc is the motor shaft.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com