A carrier pulsed eddy current detection method and device

A pulsed eddy current and detection method technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve problems such as environmental pollution, complex probe installation operations, constraints, etc., to simplify pulsed eddy current detection instruments, facilitate signal acquisition, and attenuate speed Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

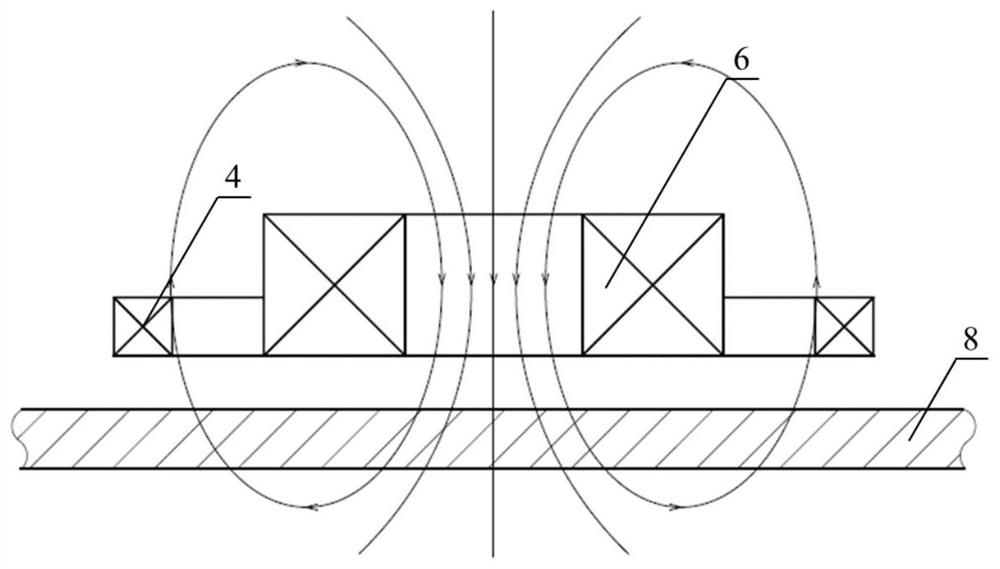

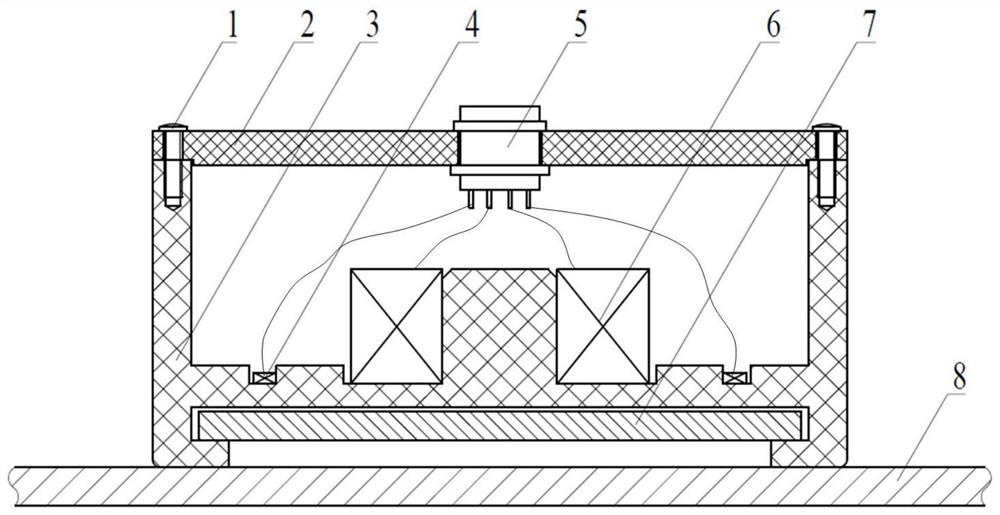

[0041] Obtain the original pulsed eddy current detection signal of a small-diameter pipe made of 304 stainless steel, with an outer diameter of 50 mm and a wall thickness of 10 mm through the above-mentioned device, and the metal plate used is an aluminum plate with a thickness of 6 mm;

[0042] Install the aluminum plate under the pulsed eddy current sensor, apply square wave excitation, and obtain the carrier signal; then place the small-diameter tube under the pulsed eddy current sensor installed with the aluminum plate, apply square wave excitation, and obtain the modulation signal; the obtained carrier signal and modulation signal are as follows: Figure 4 As shown, the vertical axis represents the induced voltage (V), and the horizontal axis represents the time (s);

[0043] Make a difference between the carrier signal and the modulation signal to obtain the modulation and demodulation signal, that is, the original pulsed eddy current detection signal of the small-diamete...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com