Vehicle profile measurement method based on vector image measurement

A vehicle profile and image measurement technology, which is applied to measurement devices, instruments, and optical devices, etc., can solve the problems of inability to provide effective guidance and suggestions for vehicle maintenance operations, inability to quantitatively measure dimensions, and high equipment failure rates. Real-time On-site picture visualization monitoring, real-time disease classification management, simple layout effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

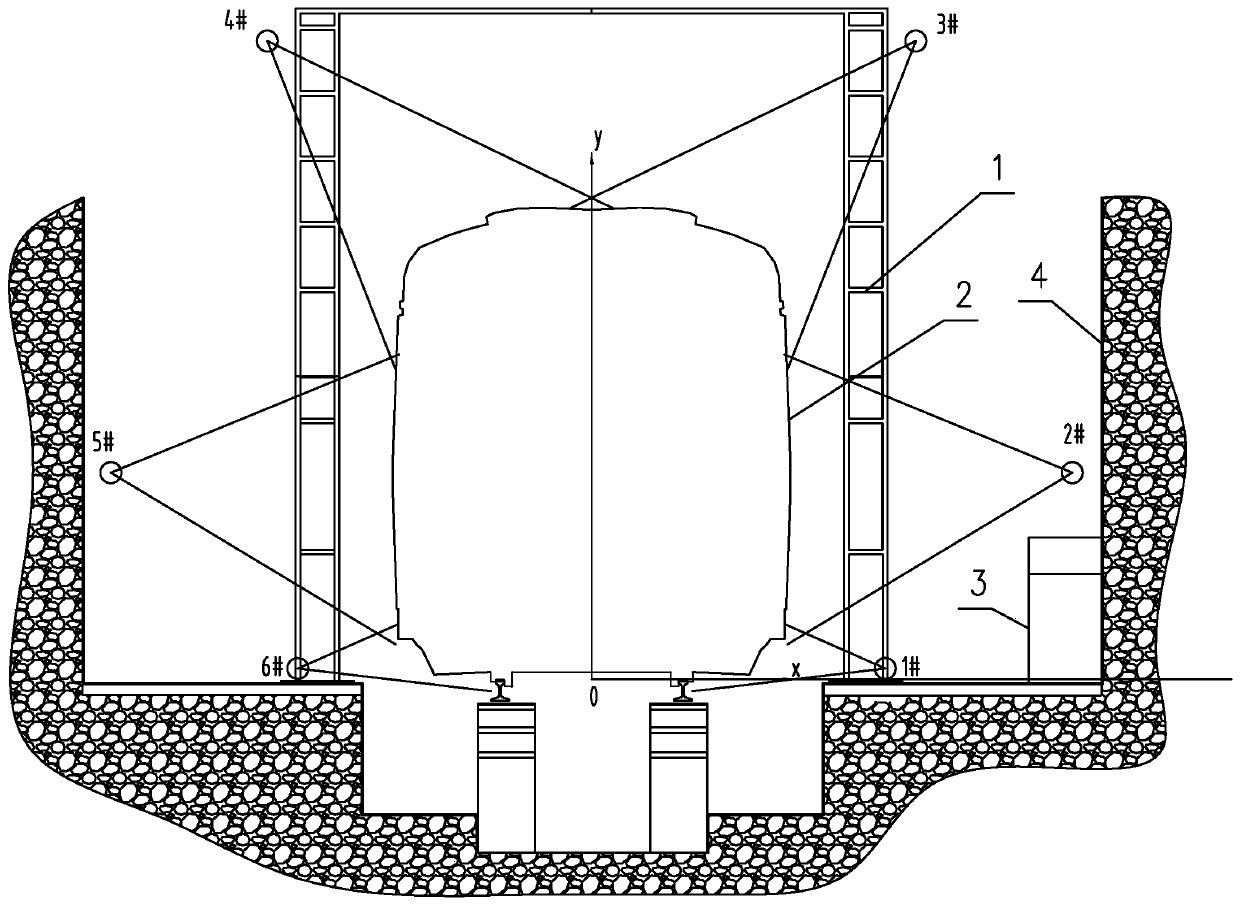

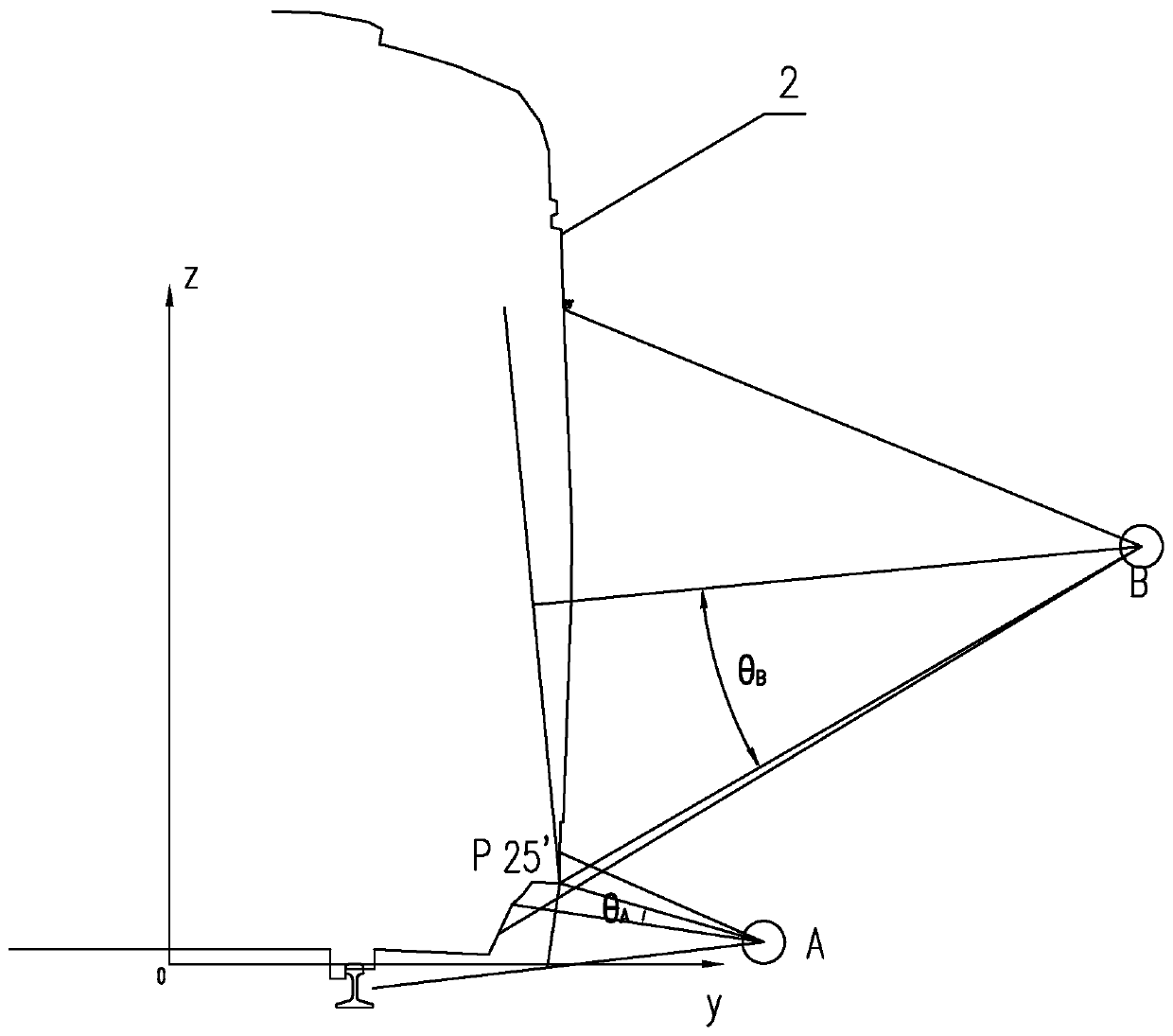

[0043] A vehicle profile measurement method based on vector image measurement in the present invention, such as figure 1 As shown, the side wall 4 of the tunnel in the detection area is provided with a limited detection cabinet 3 and a vehicle boundary line 2 . Define the space vector measurement coordinate system: the x-axis points to the positive direction of the paper, indicating the direction of travel of the train; the x-axis rotates 90° counterclockwise, which is the positive direction of the y-axis; the y-axis rotates 90° clockwise, which is the positive direction of the z-axis .

[0044] Several definitions:

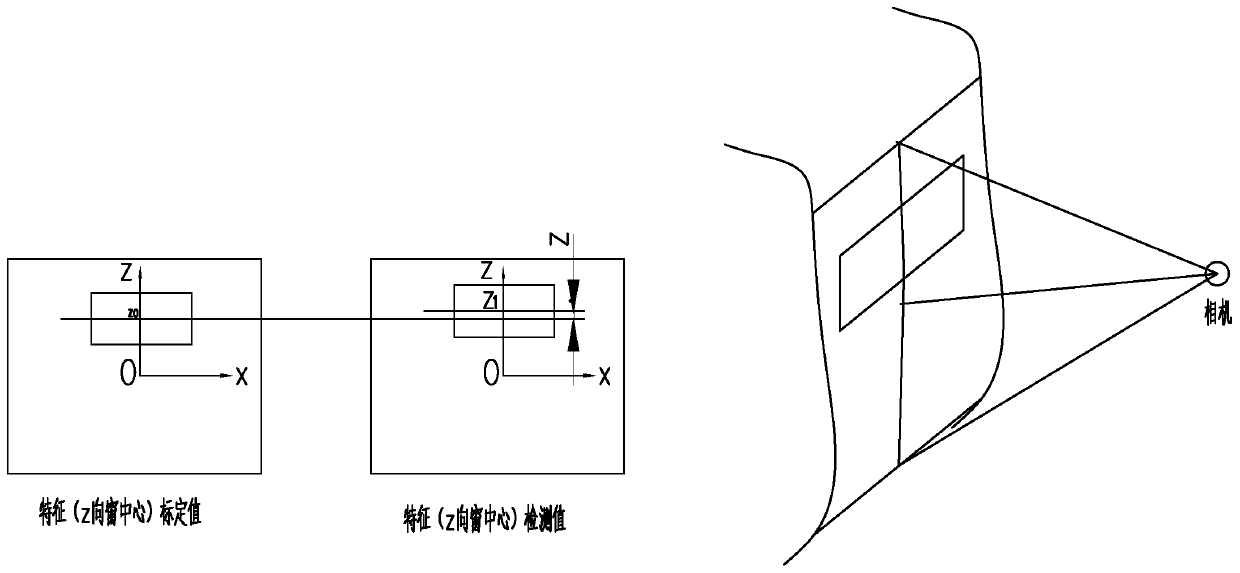

[0045] Object outline: CJJ / T 96-2018 "Metro Gauge Standard" stipulates the three-dimensional coordinate values of the outline points in the spatial coordinate system (referenced by the rail plane and center line); and eliminates the influence of dynamic settlement and lateral offset of the track.

[0046] Line array plane: the angle between the length directi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com