Active oxygen generator special for various fuel boilers

An active oxygen generator and boiler technology, applied in the field of boiler energy saving and emission reduction, can solve problems such as insufficient combustion of boiler fuel, fuel heat release affecting boiler efficiency, interference of actual oxygen utilization rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

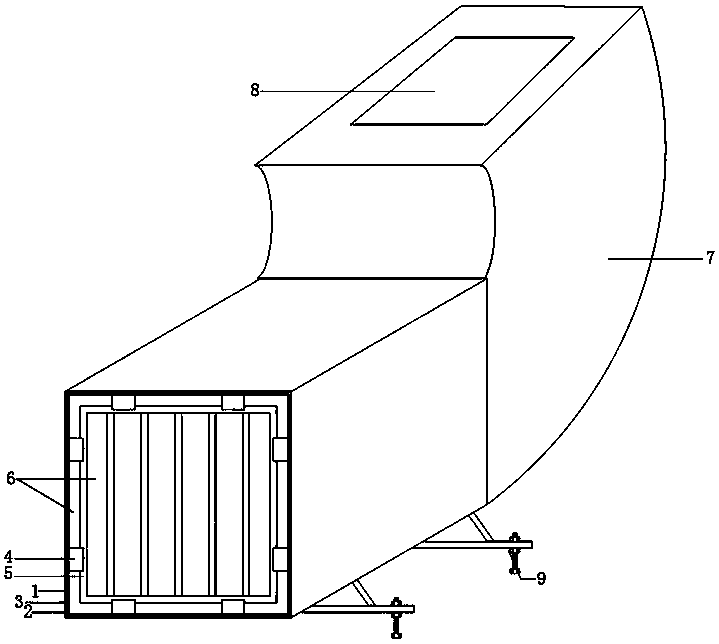

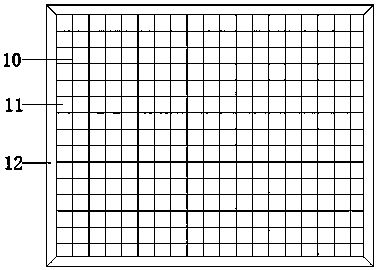

[0021] Embodiment 1: as figure 1 and image 3 As shown, a special active oxygen generator for boilers with multiple fuels, including an inner cover plate 1, an outer cover plate 2, an anti-seepage and diffusion guard plate 3, and several negative oxygen ion release templates 5 combined by welding and connecting negative oxygen ion templates . The negative oxygen ion template includes a template frame 12, a template 11, and metal protection nets 10 on both sides of the template 11. The release negative oxygen ion pattern 5 is welded with the inner cover plate 1 with the connector 4, and the bottom of the outer cover plate 2 is provided with a stable support 9 for installing and fixing the active oxygen generator. The active oxygen generator air inlet is provided with a dust-proof net, and when the air outlet 8 is docked with the boiler air inlet, it can be connected with the connecting body 7 with an elbow or a straight connection. The cross section of the active oxygen gene...

Embodiment 2

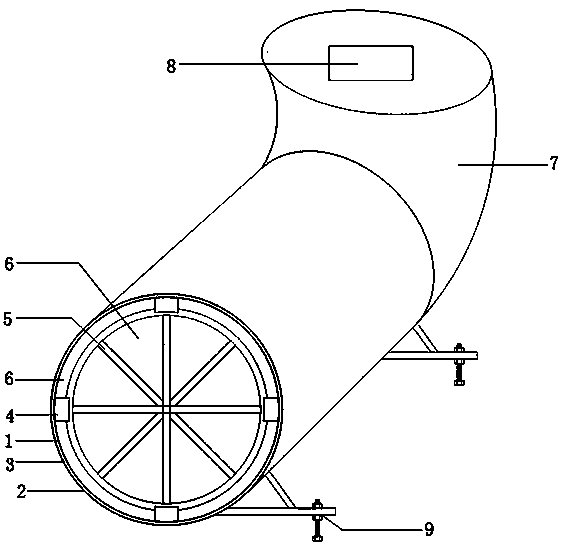

[0023] Embodiment 2: as figure 2 As shown, a special active oxygen generator for various fuel boilers, the cross section of the active oxygen generator is circular, and other structures are the same as in embodiment 1.

[0024] The application of the patent of the present invention is installed at the air inlet of the boiler blower, and when the boiler blower is started, the external air enters the combustion chamber of the boiler through the patent of the present invention. The negative oxygen ion phantom 5 released by the patent of the present invention can release up to 50,000 / cm³ / s, and it is a long-term usable energy source. When the outside air enters the patent of this invention, the oxygen molecules in the air can be turned into single oxygen atoms, and a large number of negative oxygen ions will be generated to become unsaturated oxygen. Accelerate the oxidation reaction, thereby greatly improving the combustion effect, and the flame brightness is greatly improved. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com