A static pressure prefabricated pool and its construction method

A prefabricated assembly and construction method technology, which is applied in the configuration of water supply pools, buildings, waterway systems, etc., can solve problems such as large amount of earthwork excavation and backfill, unsuitable narrow spaces, deformation of surrounding buildings, etc., to save engineering costs , Save the construction process and save the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0031] A method for constructing a static pressure prefabricated pool, comprising the following steps:

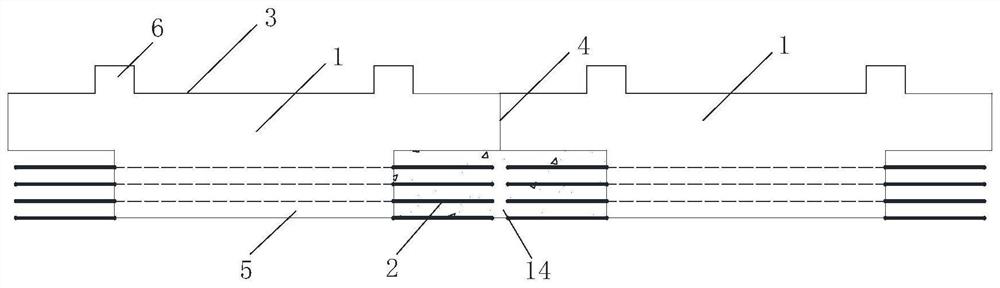

[0032] Step 1: Process the prefabricated block 1 according to the pool wall structure;

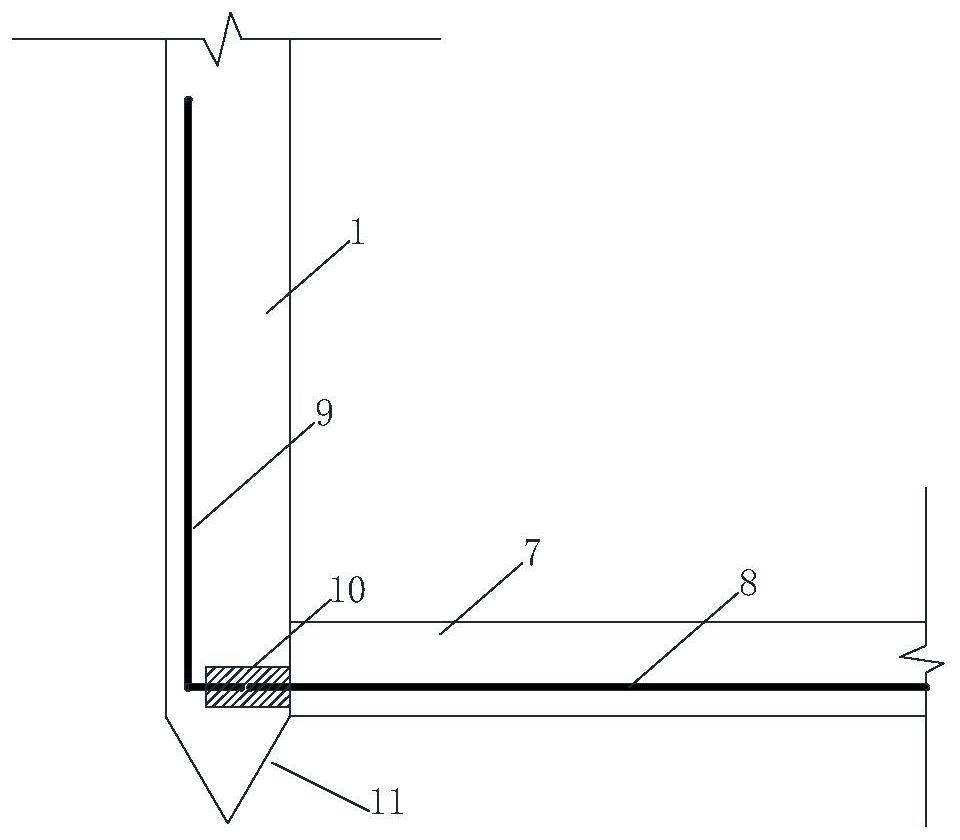

[0033] Such as figure 1 As shown, the prefabricated block 1 is a lath-shaped reinforced concrete structure. The prefabricated block 1 includes a middle plate body 3, a web 5 and a reinforcing rib 6. The web 5 is located inside the middle plate body 3, and the reinforcing rib 6 is located in the middle plate. The outer side of the body 3; the exposed steel bars 2 are reserved on both sides of the web 5, and the flanges 4 at both ends of the adjacent prefabricated block 1 are fitted together after being pressed in, which can prevent the outer soil from sliding into the pool caused by the excavation of the internal soil later. The cavities between adjacen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com