Production method of fibers for antibacterial and durable mattress fabric

A mattress and fabric technology, applied in fiber processing, plant fibers, flame-retardant fibers, etc., can solve problems such as poor softness and poor wear resistance, and achieve the effects of avoiding short service life, prolonging service life, and enhancing antibacterial properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

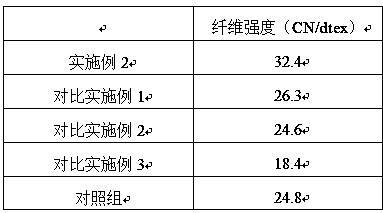

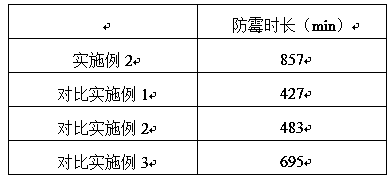

Examples

Embodiment 1

[0033] A kind of antibacterial, the preparation method of durable mattress fabric fiber, comprises the steps:

[0034] (1) Pretreatment of raw bamboo fiber:

[0035] a. drop the raw bamboo fiber into the pulverizer to pulverize, and cross 100 mesh sieves to get the raw bamboo fiber powder for subsequent use after pulverizing;

[0036] b. First put fulvic acid and fulvic acid into a sterile beaker filled with purified water in a weight ratio of 3:1, and keep stirring until the fulvic acid and fulvic acid are completely dissolved. Seal with plastic wrap and place at 0°C After being placed in an environment for 30 minutes, the original bamboo fiber powder obtained in operation a was immersed in the prepared solution in an environment of 0°C, and stirred continuously at a speed of 50 rpm, and ultrasonic treatment of a specific frequency was carried out while stirring, and the stirring treatment After 45 minutes, centrifuge, wash with ice ethanol for 3 times, and dry until the moi...

Embodiment 2

[0056] A kind of antibacterial, the preparation method of durable mattress fabric fiber, comprises the steps:

[0057] (1) Pretreatment of raw bamboo fiber:

[0058] a. drop the raw bamboo fiber into the pulverizer and pulverize, and cross 130 mesh sieves to get the raw bamboo fiber powder for subsequent use after pulverizing;

[0059] b. Put the fulvic acid and fulvic acid into a sterile beaker filled with purified water in sequence according to the weight ratio of 3.5:1.5, and keep stirring until the fulvic acid and fulvic acid are completely dissolved. Seal with plastic wrap and place at 2°C After being placed in an environment for 35 minutes, the raw bamboo fiber powder obtained in operation a was immersed in the prepared solution in an environment of 2°C, and stirred continuously at a speed of 60 rpm, and ultrasonic treatment of a specific frequency was carried out while stirring, and the stirring treatment After 50 minutes, centrifuge, wash with ice ethanol for 4 times,...

Embodiment 3

[0079] A kind of antibacterial, the preparation method of durable mattress fabric fiber, comprises the steps:

[0080] (1) Pretreatment of raw bamboo fiber:

[0081] a. the original bamboo fiber is dropped into the pulverizer and pulverized, and after the pulverization, 160 mesh sieves are used to obtain the original bamboo fiber powder for subsequent use;

[0082] b. First put fulvic acid and fulvic acid into a sterile beaker filled with purified water in a weight ratio of 4:2, and keep stirring until the fulvic acid and fulvic acid are completely dissolved, then seal with plastic wrap and place at 4°C After being placed in the environment for 40 minutes, the raw bamboo fiber powder obtained in operation a was immersed in the prepared solution in an environment of 4°C, and stirred continuously at a speed of 70 rpm, and ultrasonic treatment of a specific frequency was carried out while stirring, and the stirring treatment After 55 minutes, centrifuge, wash with ice ethanol fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com