A well kill plugging slurry and plugging method for well completion and oil testing

A plugging method and a technology of plugging slurry, which are applied in wellbore/well components, chemical instruments and methods, earthwork drilling and production, etc., and can solve the problem of low plugging success rate of thin bridge plugs and plugging agents while drilling, and downhole problems. Problems such as plugging of the perforation test string and failure of the packer to be unsealed smoothly, to avoid plugging and jamming accidents, improve pressure bearing capacity, and improve retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

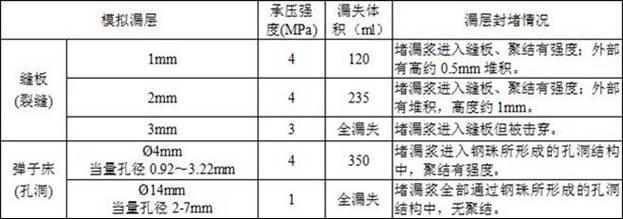

Examples

Embodiment 1

[0043] The invention discloses a well-killing plugging slurry for well completion testing. Based on conventional well-completion well-killing fluids, the following components are added in terms of the mass percentage of conventional well-completion well-killing fluids:

[0044] A. LWD plugging agent SDL: 4.5%;

[0045] B. Temporary plugging agent PCC for drilling fluid: 4.0%;

[0046] C. Composite plugging agent FDJ-Ⅰ: 3.0%;

[0047] D. Flexible mesh fiber plugging agent AT-FB: 0.2%;

[0048] The processing length of the flexible mesh fiber lost circulation agent AT-FB is 19mm, and the equivalent diameter is <100um.

[0049] The plugging agent SDL while drilling is an existing technology, and its implementation standard refers to the enterprise standard Q / 77982897-8.1-2017 of Sichuan Hengyi Technology Co., Ltd.

[0050] The processing length of the flexible mesh fiber lost circulation agent AT-FB is 12-19mm, and the equivalent diameter is <100um. The fiber has strong suspe...

Embodiment 2

[0057] The invention discloses a well-killing and plugging slurry for well completion testing. Based on conventional well-completion well-killing fluids, the following components are added in terms of the mass percentage of conventional well-completion well-killing fluids:

[0058] A. LWD plugging agent SDL: 5%;

[0059] B. Temporary plugging agent PCC for drilling fluid: 5%;

[0060] C. Composite plugging agent FDJ-I: 5.5%;

[0061] D. Flexible mesh fiber plugging agent AT-FB: 0.5%;

[0062] The processing length of the flexible network fiber lost circulation agent AT-FB is 12mm, and the equivalent diameter is <100um.

Embodiment 3

[0064] The invention discloses a well-killing and plugging slurry for well completion testing. Based on conventional well-completion well-killing fluids, the following components are added in terms of the mass percentage of conventional well-completion well-killing fluids:

[0065] A. Plugging agent SDL while drilling: 5.0%;

[0066] B. Temporary plugging agent PCC for drilling fluid: 5.0%;

[0067] C. Composite plugging agent FDJ-I: 5%;

[0068] D. Flexible mesh fiber plugging agent AT-FB: 0.4%;

[0069] The processing length of the flexible mesh fiber lost circulation agent AT-FB is 15mm, and the equivalent diameter is <100um.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com