Biodegradable bacteriostatic film with high mechanical properties and preparation process thereof

A mechanical and performance technology, applied in the field of biodegradable antibacterial films, can solve the problems of plastic film being difficult to degrade, difficult to popularize and apply on a large scale, poor in strength and stretchability, etc., to increase elongation at break, good antibacterial effect, The effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

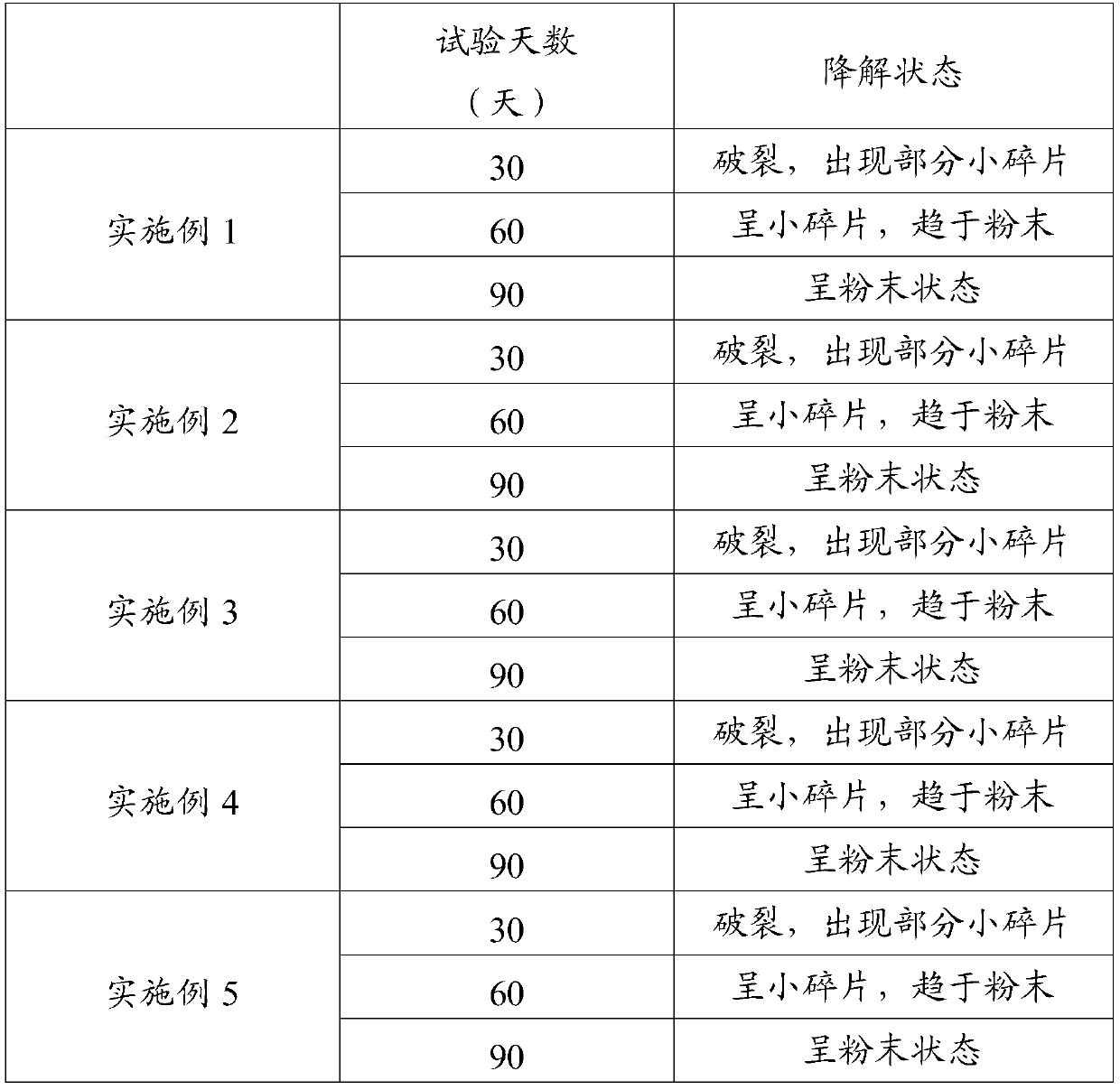

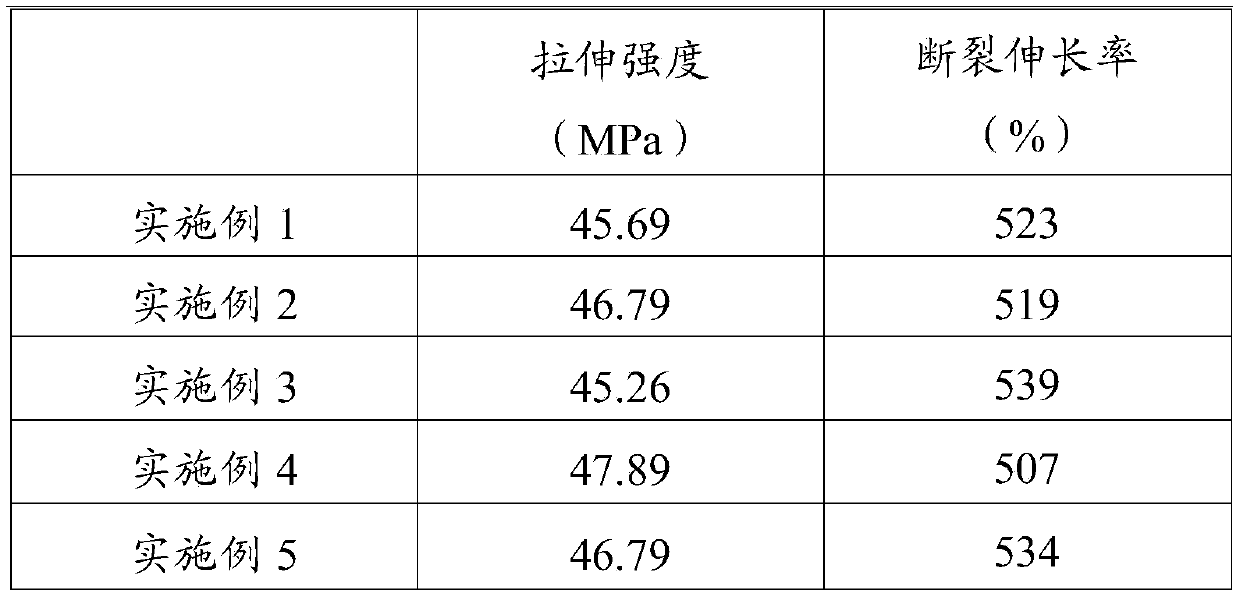

Examples

Embodiment 1

[0049] A biodegradable antibacterial film with high mechanical properties, comprising the following raw materials in parts by weight:

[0050] 80 parts of polyethylene, 30 parts of L-polylactic acid with a relative molecular weight of 100,000, 20 parts of octenyl succinic esterified corn starch, 15 parts of wheat straw with a particle size of 100-200 nm, 10 parts of sugarcane fiber, 4 parts of common Lulan polysaccharide, 4 parts of oxidized polyethylene wax, 2 parts of polysorbate, 1 part of tributyl acetate, 3 parts of bamboo charcoal powder with a particle size of 50-100nm, 1 part of calcium ricinoleate, 5 parts of a particle size of 5- 10nm indica glutinous rice flour, 5 parts of medical stone with a particle size of 100-200nm, 7 parts of kaolin with a particle size of 200-300nm, 4 parts of Yuan Mingfen with a particle size of 5-10nm, and 3 parts of a particle size of 50-200nm 100nm coconut shell powder, 3 parts polybutylene succinate, 2 parts polyester fiber;

[0051] Po...

Embodiment 2

[0056] A biodegradable antibacterial film with high mechanical properties, comprising the following raw materials in parts by weight:

[0057] 100 parts of polyethylene, 20 parts of L-polylactic acid with a relative molecular weight of 200,000, 30 parts of tapioca starch esterified with octenyl succinate, 10 parts of wheat straw with a particle size of 100-200 nm, 5 parts of ramie fiber, and 7 parts of common Lulan polysaccharide, 3 parts of oxidized polyethylene wax, 3 parts of polysorbate, 2 parts of triacetin, 5 parts of bamboo charcoal powder with a particle size of 50-100nm, 2 parts of calcium ricinoleate, 10 parts of a particle size of 5-100nm 10nm indica glutinous rice flour, 3 parts of medical stone with a particle size of 100-200nm, 5 parts of kaolin with a particle size of 200-300nm, 5 parts of Yuan Mingfen with a particle size of 5-10nm, 4 parts of a particle size of 50-200nm 100nm coconut shell powder, 2 parts polybutylene succinate, 3 parts polyester fiber;

[00...

Embodiment 3

[0063] A biodegradable antibacterial film with high mechanical properties, comprising the following raw materials in parts by weight:

[0064] 85 parts of polyethylene, 23 parts of L-polylactic acid with a relative molecular weight of 150,000, 26 parts of octenyl succinic esterified wheat starch, 12 parts of wheat straw with a particle size of 100-200nm, 7 parts of sugarcane fiber, 5 parts of common Lulan polysaccharide, 3.6 parts of oxidized polyethylene wax, 2.3 parts of polysorbate, 1.3 parts of tributyl acetate, 4.5 parts of bamboo charcoal powder with a particle size of 50-100nm, 1.3 parts of zinc stearate, 7 parts of a particle size of 5-100nm 10nm indica glutinous rice flour, 4.5 parts of medical stone with a particle size of 100-200nm, 6.5 parts of kaolin with a particle size of 200-300nm, 4.6 parts of Yuan Mingfen with a particle size of 5-10nm, 3.4 parts of a particle size of 50- 100nm coconut shell powder, 2.6 parts of polybutylene succinate, 2.7 parts of polyester ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com