Preparation method of porous network structure graphene/polyaniline composite dry gel

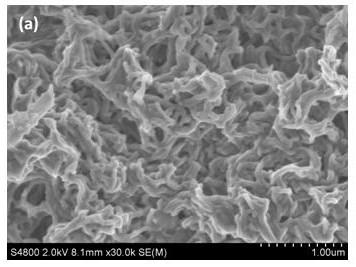

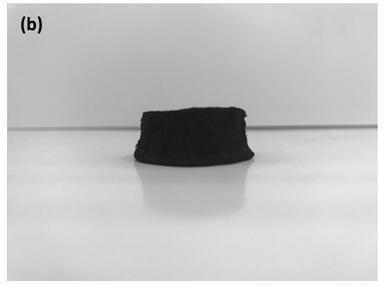

A technology of network structure and composite hydrogel, which is applied in the field of preparation of porous network structure graphene/polyaniline composite xerogel, can solve the problem of non-self-supporting supercapacitor electrodes, poor mechanical strength of PANI hydrogel, and influence on electrolysis Liquid diffusion ion migration and other issues, to achieve the effect of good electrochemical cycle stability, conducive to diffusion and transmission, and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] A method for preparing a high-strength three-dimensional porous network structure graphene / polyaniline composite xerogel, comprising the following steps:

[0020] (1) Preparation of graphene oxide (GO): GO was prepared by the improved Hummers method;

[0021] (2) Preparation of cross-linked polyaniline conductive paste: 5 mg of PPD and 50 mg of aniline were dissolved in 20 ml of phytic acid solution, and 0.25 g of ammonium persulfate was dissolved in 10 ml of phytic acid solution. The concentration is 0.05 mol / liter, the temperature of the above two groups of solutions is controlled at 0°C, quickly mix the two groups of solutions and stir vigorously, stop stirring when the solution starts to change color, and let it stand for 3 hours to obtain cross-linked conductive polyaniline slurry;

[0022] (3) Preparation of high-strength three-dimensional porous network structure graphene / polyaniline composite xerogel: the polyaniline conductive slurry was directly mixed with th...

Embodiment 2

[0025] A high-strength three-dimensional porous network structure graphene / polyaniline composite xerogel method, comprising the following steps:

[0026] (1) Preparation of graphene oxide (GO): GO was prepared by the improved Hummers method;

[0027] (2) Preparation of cross-linked polyaniline conductive paste: 5 mg of PPD and 100 mg of aniline were dissolved in 20 ml of phytic acid solution, and 0.5 g of ammonium persulfate was dissolved in 10 ml of phytic acid solution. The concentration is 0.1 mol / liter. The temperature of the above two groups of solutions is controlled at 0°C. The two groups of solutions are quickly mixed and stirred vigorously. When the solution starts to change color, stop stirring and let it stand for 3 hours. Obtain cross-linked conductive polyaniline paste;

[0028] (3) Preparation of high-strength three-dimensional porous network structure graphene / polyaniline composite xerogel: the polyaniline conductive slurry was directly mixed with the GO disper...

Embodiment 3

[0030] A high-strength three-dimensional porous network structure graphene / polyaniline composite xerogel method, comprising the following steps:

[0031] (1) Preparation of graphene oxide (GO): GO was prepared by the improved Hummers method;

[0032] (2) Preparation of cross-linked polyaniline conductive paste: 10 mg of PPD and 200 mg of aniline were dissolved in 20 ml of phytic acid solution, and 1 g of ammonium persulfate was dissolved in 10 ml of phytic acid solution. The concentration is 0.05 mol / liter, the temperature of the above two groups of solutions is controlled at 0°C, quickly mix the two groups of solutions and stir vigorously, stop stirring when the solution starts to change color, and let it stand for 3 hours to obtain cross-linked conductive polyaniline slurry;

[0033] (3) Preparation of high-strength three-dimensional porous network structure graphene / polyaniline composite xerogel: the polyaniline conductive slurry was directly mixed with the GO dispersion t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com