Automatic stamping assembly line

An assembly line and automatic technology, applied in metal processing equipment, feeding devices, manufacturing tools, etc., to reduce production costs, improve production stability and safety, and improve production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

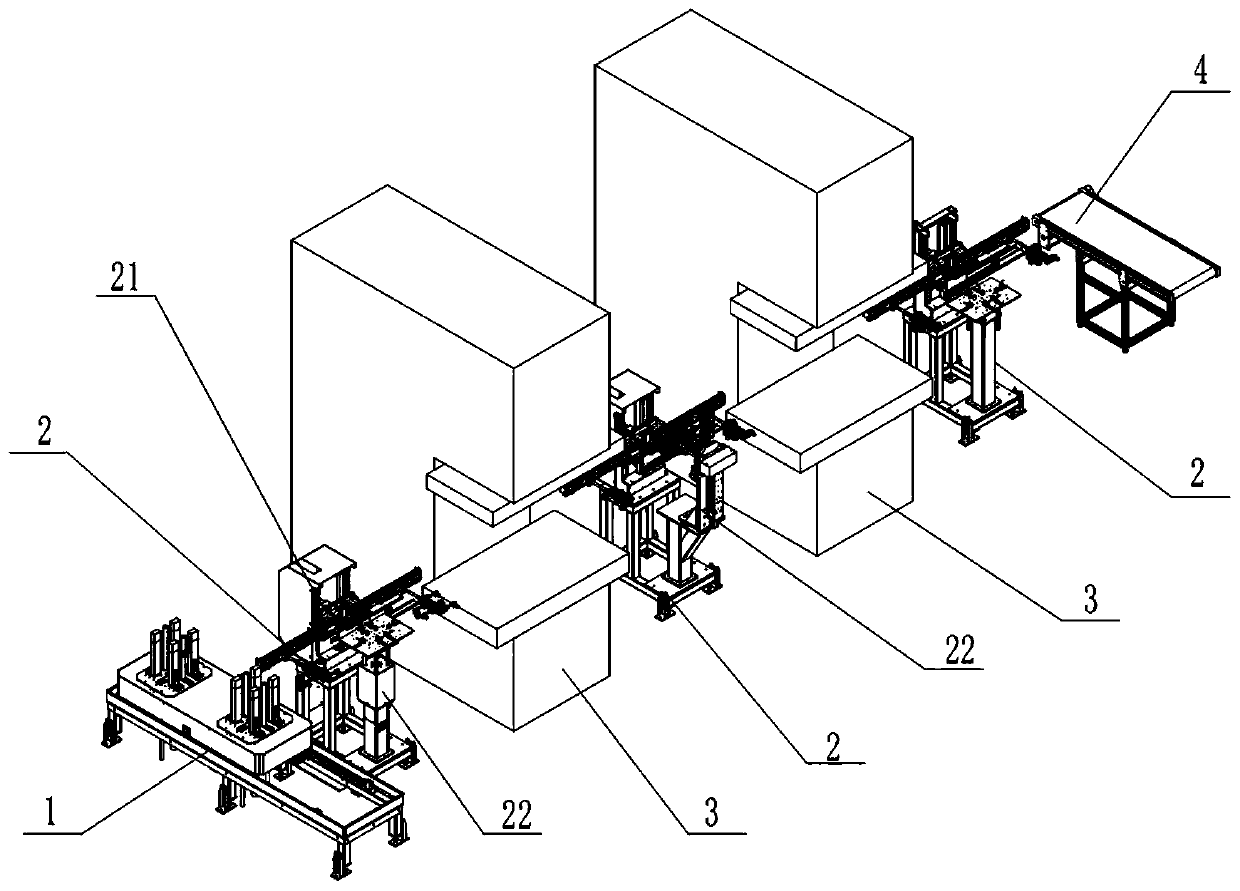

[0026] Such as figure 1 As shown, an automatic stamping assembly line, automatic feeding platform 1, 1# manipulator assembly 2 with height compensation platform, 1# press 3, 2# manipulator assembly 2 with flipping device, 2# press 3 , 3# manipulator assembly 2 with height compensation platform, conveyor belt assembly 4.

[0027] Such as figure 2 As shown, the automatic feeding platform 1 is vertically arranged, and has a lifting platform 11 equipped with two stacking platforms 12. The lifting platform 11 is driven up and down by a lift driven by a servo motor, and moved back and forth by a cylinder drive. A plurality of magnetic stratifiers 13 are arranged on the stacking plate 12 of the automatic feeding platform 1 .

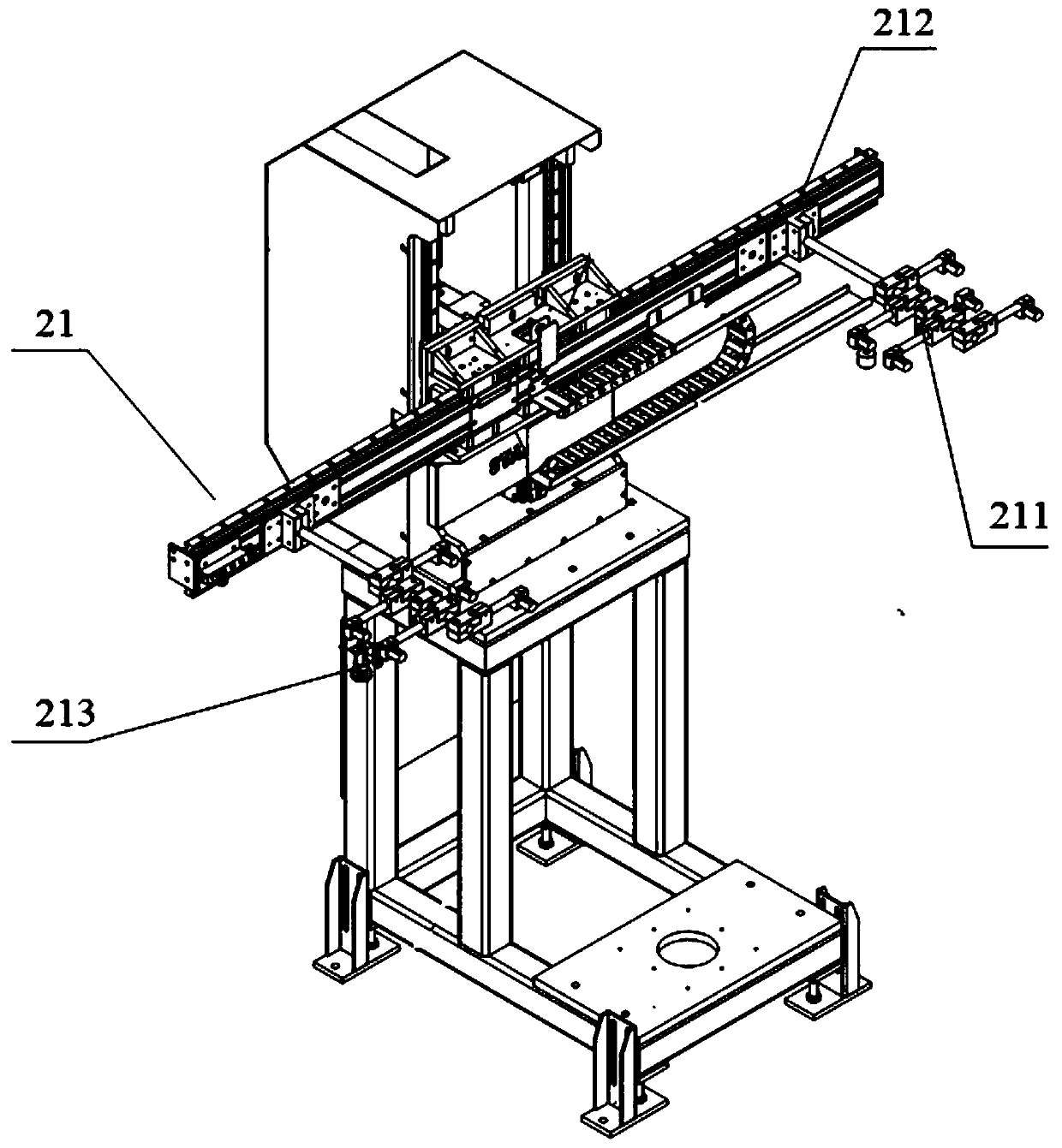

[0028] Manipulator assembly 2 includes such as image 3 The shown manipulator 21 with two manipulator arms 211 is located at the transfer station 22 in front of the manipulator 21 . The manipulator 21 includes an X-axis guide rail 212 and two mechanical ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com