Strong rock burst roadway supporting method

A technology of rock burst and roadway support, applied in tunnels, tunnel linings, underground chambers, etc., can solve the problems of anchor bolts not being able to prevent scour, overall instability and damage, and reducing the bearing capacity of supports, etc., to achieve Guarantee the mechanical properties of impact resistance, ensure safe and efficient mining, and improve the effect of safety protection coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to better explain the present invention and facilitate understanding, the technical solutions and effects of the present invention will be described in detail below through specific implementation manners in conjunction with the accompanying drawings.

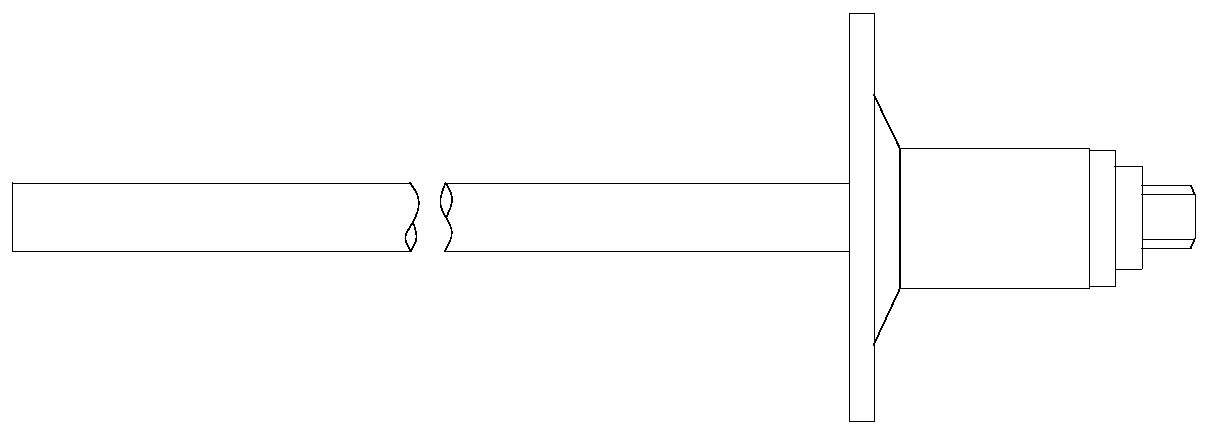

[0029] Such as Figure 7 As shown, a rock burst roadway support method is to adopt a three-stage combined support method such as anchor net 5, U-shaped shed 4, and energy-absorbing anti-scouring support 3 in the rock burst roadway, including the following steps:

[0030] Step 1: If Figure 6 As shown, after 100 cm of rock burst mine roadway is excavated, the anchor net 5 composed of energy-absorbing and anti-shock bolt 7, anchor cable 8, and rhombic metal mesh is used for primary support, and the roof and roadway side are made of rhombic metal mesh Laying, and then drill equidistant anchor installation holes on the roadway roof and side, the row spacing between the anchor installation holes is 100cm, the hole d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com