Assembled steel column base with controllable damage

An assembly type, steel column technology, applied in the direction of columns, pier columns, pillars, etc., can solve the problems of dissipating earthquake energy, economic loss, large plastic deformation of anchor bolts, etc., to achieve improved repair ability, strong energy consumption, and damage controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

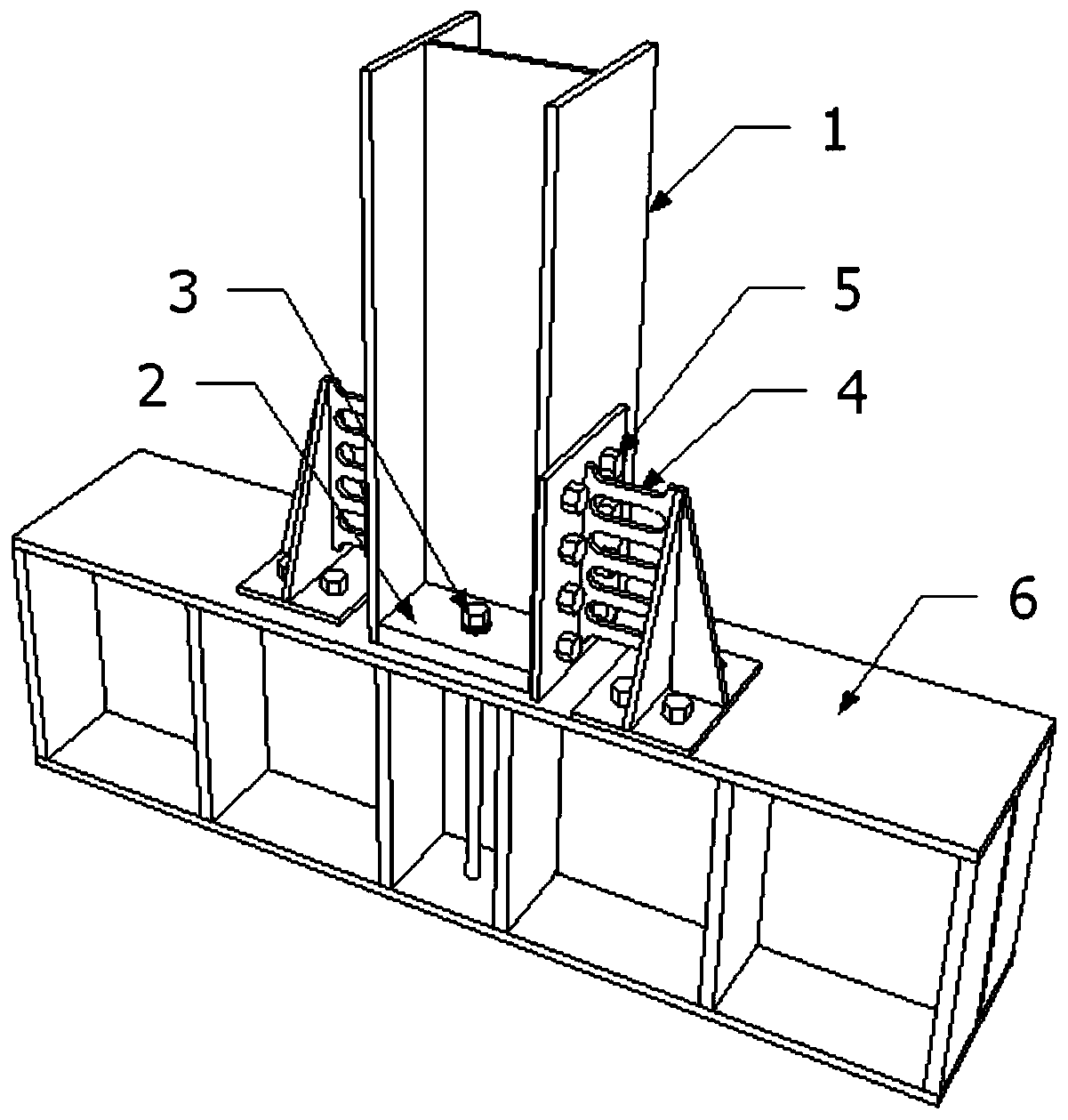

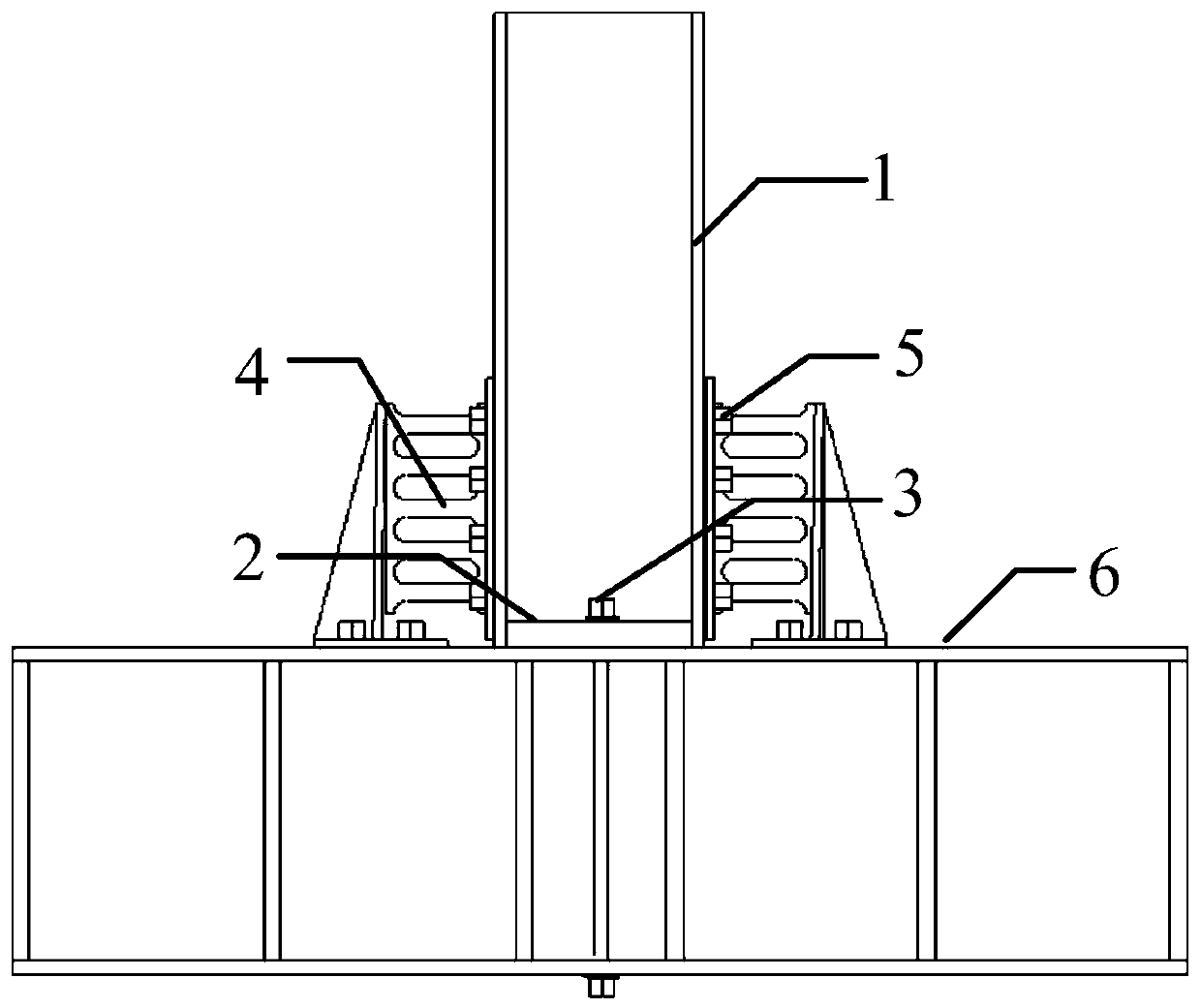

[0040] An assembled damage-controllable shear-type steel column base, including steel foundation 6, anchor bolt 3, shear-type energy dissipator 4 and steel column 1, steel foundation 6 and steel column 1 bottom plate are provided with openings, anchor bolts 3 Pass through the openings of the steel foundation 6 and the steel column bottom plate 2 and connect the steel foundation 6 and the steel column 1. The steel foundation 6 and the flange of the steel column 1 are also provided with openings according to the size of the shear energy dissipator 4, and the shear energy dissipator 4 is connected with the steel foundation 6 and the flange of the steel column 1 through high-strength bolts 5; The anchoring length of the anchor bolt 3 is not less than 25d, where d is the diameter of the anchor bolt, ensuring that the anchor bolt 3 has sufficient anchoring length and deformation capacity, and the yield strength of the shear energy dissipator 4 is less than or equal to the steel colum...

Embodiment 2

[0049] An assembled damage-controllable tension-compression steel column base, including steel foundation 6, anchor bolt 3, tension-compression energy dissipator 7 and steel column 1, steel foundation 6 and steel column 1 bottom plate are provided with openings, anchor bolts 3 Pass through the openings of the steel foundation 6 and the steel column bottom plate 2 and connect the steel foundation 6 and the steel column 1. The steel foundation 6 and the flange of the steel column 1 are also provided with openings according to the size of the tension-compression energy dissipator 7, and the tension-compression energy dissipator 7 is connected with the steel foundation 6 and the flange of the steel column 1 through high-strength bolts 5; The anchoring length of the anchor bolt 3 is not less than 25d, where d is the diameter of the anchor bolt, ensuring that the anchor bolt 3 has sufficient anchoring length and deformation capacity, and the yield strength of the tension-compression ...

Embodiment 3

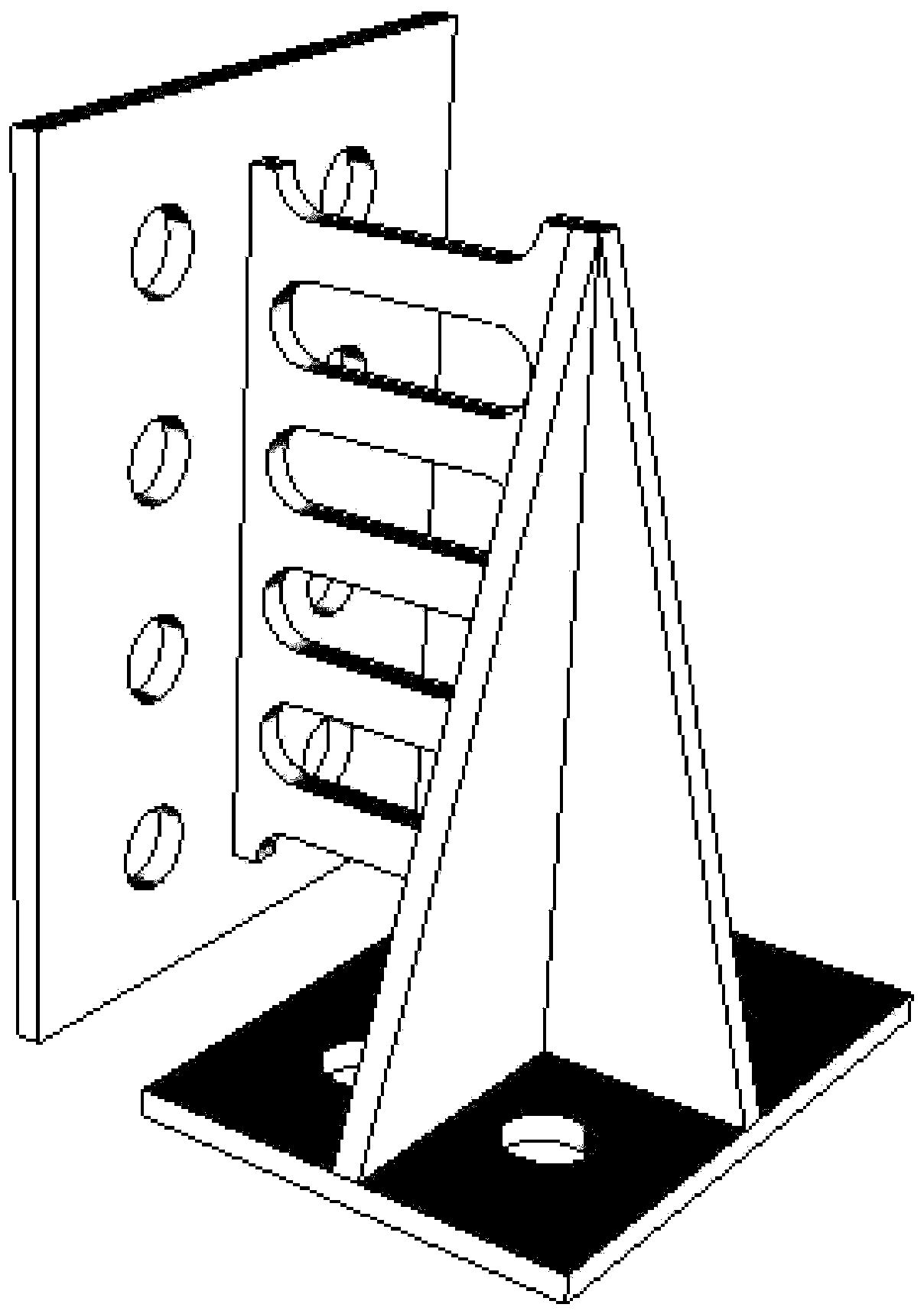

[0058] An assembled damage-controllable corner braced steel column foot, including steel foundation 6, anchor bolt 3, corner brace type energy dissipator 8 and steel column 1, steel foundation 6 and steel column 1 bottom plate are provided with openings, anchor bolts 3 Pass through the openings of the steel foundation 6 and the steel column bottom plate 2 and connect the steel foundation 6 and the steel column 1. The steel foundation 6 and the flange of the steel column 1 are also provided with openings according to the size of the corner brace type energy dissipator 8, and the corner brace type energy dissipator 8 is connected with the steel foundation 6 and the flange of the steel column 1 through high-strength bolts 5; The anchoring length of the anchor bolt 3 is not less than 25d, where d is the diameter of the anchor bolt, ensuring that the anchor bolt 3 has sufficient anchoring length and deformation capacity, and the yield strength of the corner brace type energy dissipa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Anchorage length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com