High-strength fire-resistant corrosion-resistant building steel and manufacturing method thereof

A technology of construction steel and manufacturing method, which is applied in the field of construction steel to achieve the effect of improving high temperature yield strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

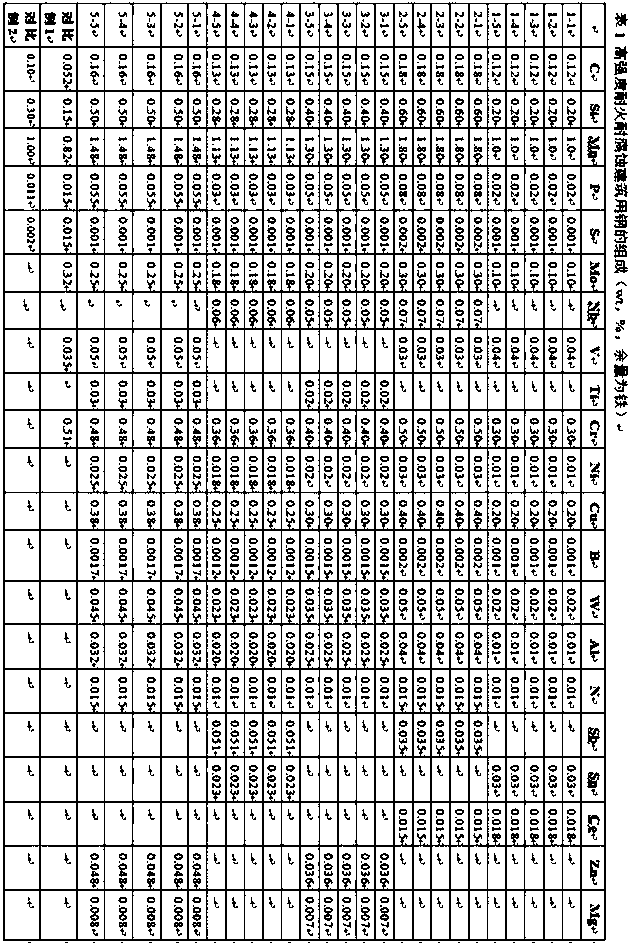

Image

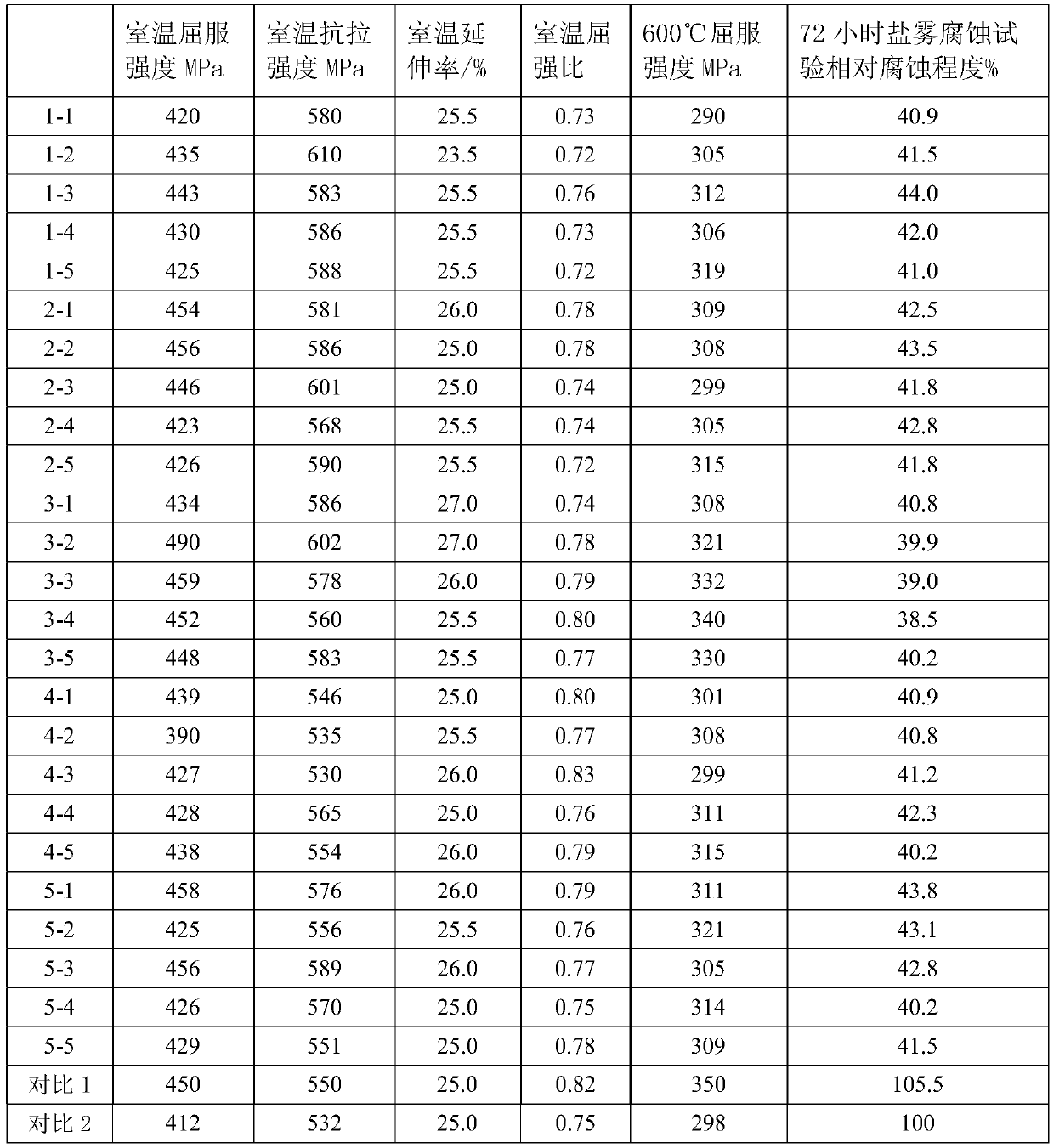

Examples

Embodiment 1-1

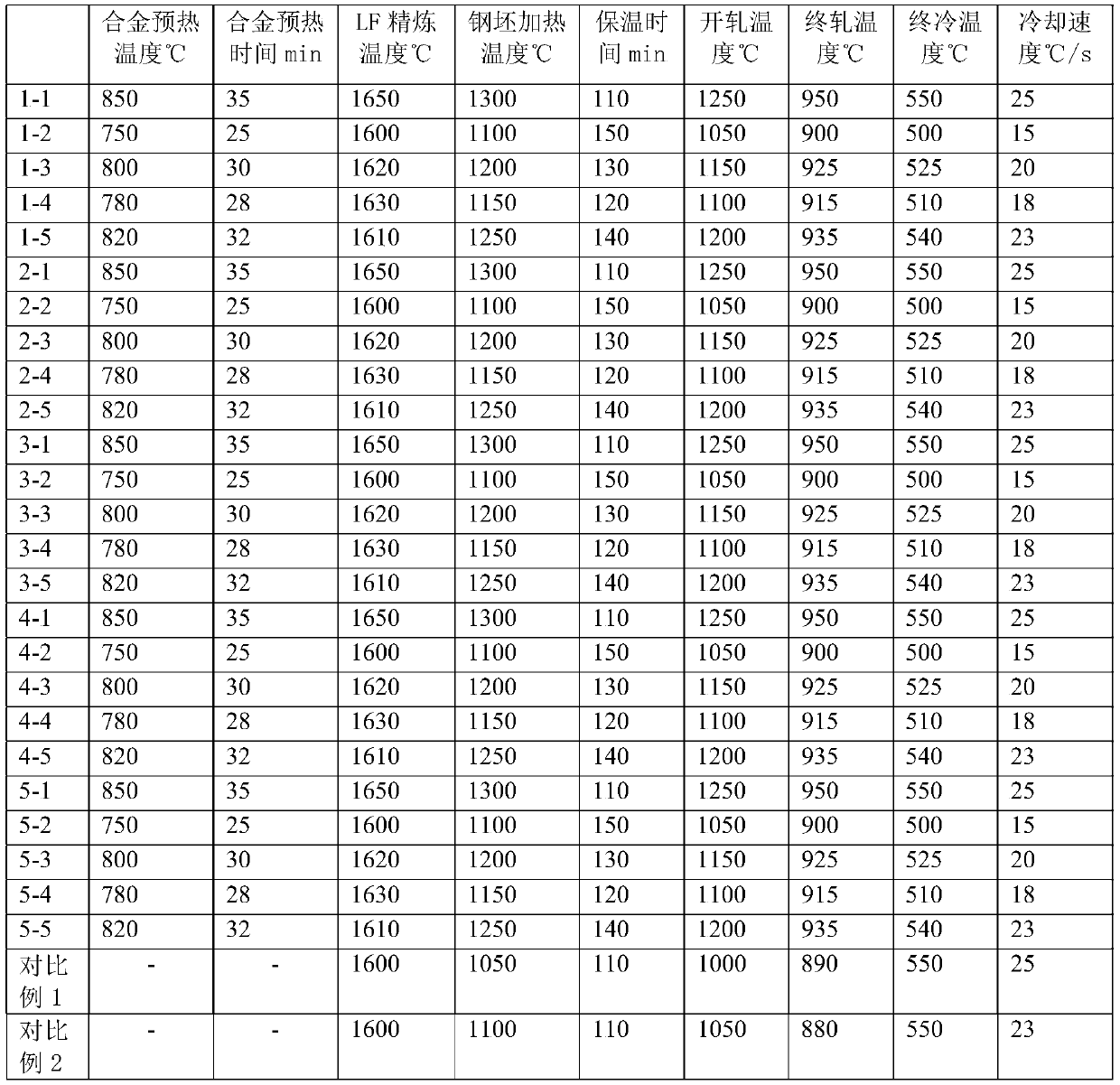

[0064] Chemical composition: C: 0.12%; Si: 0.20%; Mn: 1.0%; P: 0.02%; S: 0.001%; Mo: 0.10%; V: 0.04%; Cr: 0.30; Ni: 0.01%; Cu: 0.20 %; B: 0.001%; W: 0.02%; Al: 0.01%; N: 0.01%; Sn: 0.03%; Ce: 0.018%;

[0065] Preheat the mixture of Mo, V, Cr, Ni, Cu, B, W, Al, Sn and Ce to 850°C in the preheating furnace, add the above preheated mixture when the temperature of the LF furnace is 1650°C, and then Carry out continuous casting. After the continuous casting is completed, the billet is heated to 1300°C and held for 110 minutes. The hot rolling start temperature is 1250°C, and the final rolling temperature is 950°C. After the hot rolling is completed, the cooling rate is 25°C / s. °C, then air cooled to room temperature.

Embodiment 1-2

[0067] Chemical composition: C: 0.12%; Si: 0.20%; Mn: 1.0%; P: 0.02%; S: 0.001%; Mo: 0.10%; V: 0.04%; Cr: 0.30; Ni: 0.01%; Cu: 0.20 %; B: 0.001%; W: 0.02%; Al: 0.01%; N: 0.01%; Sn: 0.03%; Ce: 0.018%;

[0068] Preheat the mixture of Mo, V, Cr, Ni, Cu, B, W, Al, Sn and Ce to 750°C in the preheating furnace, add the above preheated mixture when the temperature of the LF furnace is 1600°C, and then Carry out continuous casting. After the continuous casting is completed, the billet is heated to 1100°C and held for 150 minutes. The hot rolling start temperature is 1050°C, and the final rolling temperature is 900°C. After the hot rolling is completed, the cooling rate is 15°C / s. °C, then air cooled to room temperature.

Embodiment 1-3

[0070] Chemical composition: C: 0.12%; Si: 0.20%; Mn: 1.0%; P: 0.02%; S: 0.001%; Mo: 0.10%; V: 0.04%; Cr: 0.30; Ni: 0.01%; Cu: 0.20 %; B: 0.001%; W: 0.02%; Al: 0.01%; N: 0.01%; Sn: 0.03%; Ce: 0.018%;

[0071] Preheat the mixture of Mo, V, Cr, Ni, Cu, B, W, Al, Sn and Ce to 800°C in the preheating furnace, add the above preheated mixture when the temperature of the LF furnace is 1620°C, and then Carry out continuous casting. After the continuous casting is completed, the billet is heated to 1200°C and held for 130 minutes. The hot rolling start temperature is 1150°C, and the final rolling temperature is 925°C. After the hot rolling is completed, the cooling rate is 20°C / s. °C, then air cooled to room temperature.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com