Method for modifying metal part by adopting electricity, magnetism and electricity and magnetism coupled pulses

A metal parts, electromagnetic coupling technology, applied in the field of metal parts modification, can solve the problems of safety factor concealment, metal parts damage, inability to completely eliminate the internal stress and microscopic defects of metal parts, etc., to achieve the effect of improving service performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0015] A method for modifying metal parts using electric, magnetic and electromagnetic coupling pulses, comprising the steps of:

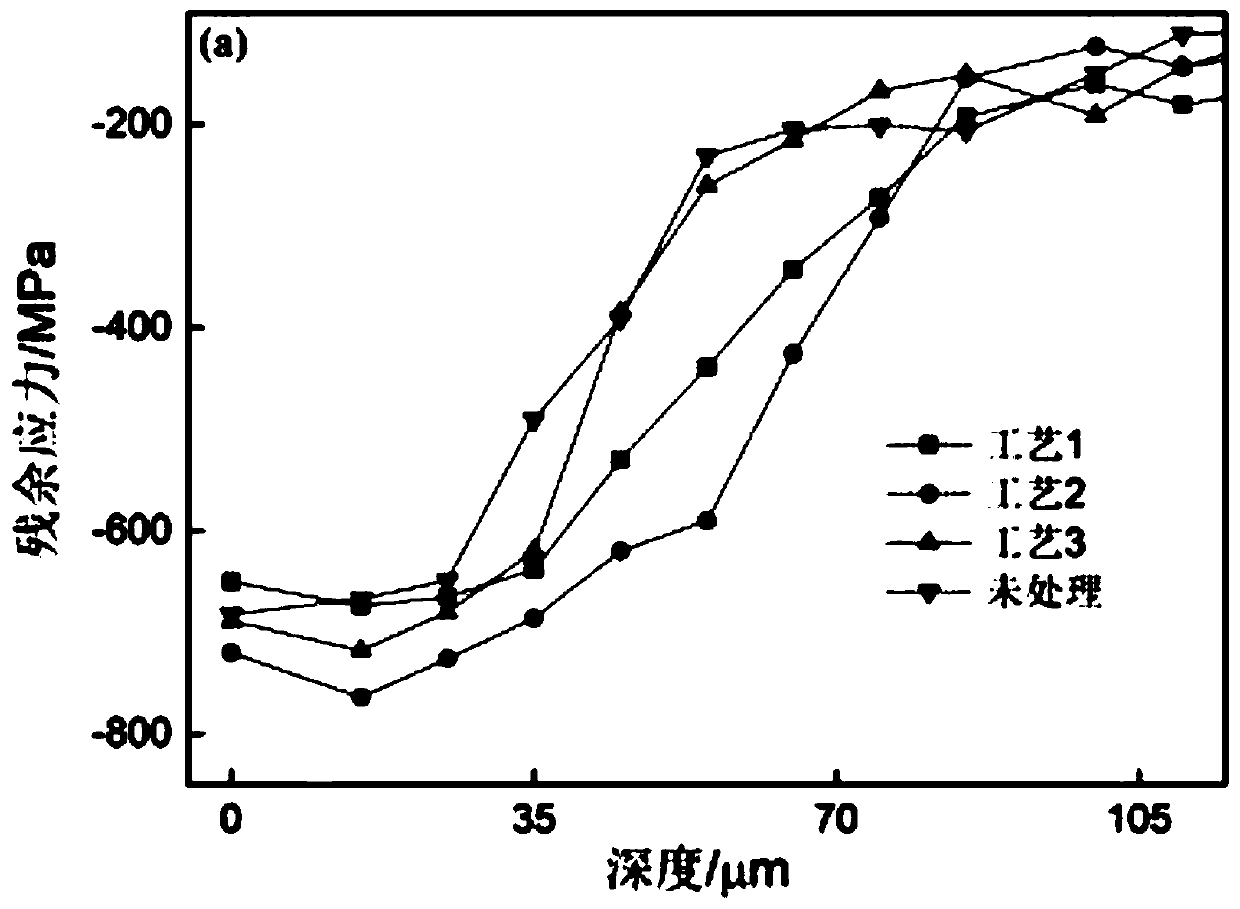

[0016] 1) Use electric, magnetic and electromagnetic coupling pulse generators to modify metal parts, apply pulsed electric field and / or pulsed magnetic field to metal parts respectively, and the pulsed electric field current is less than 1000A / mm 2 , the pulsed magnetic field strength is less than 3T;

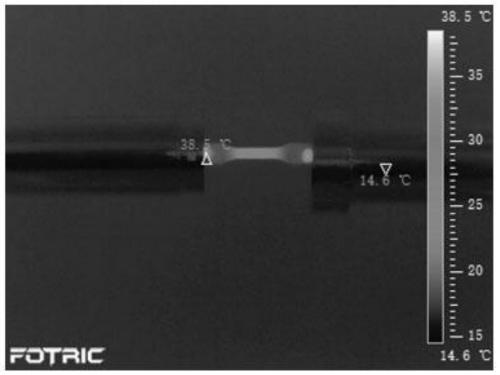

[0017] 2) During the modification process, when the surface temperature of the metal part increases to 50°C, stop applying the pulse until the surface temperature of the metal part drops to 25±0.5°C, then measure the resistance of the metal part, when the measured resistance value is compared with the modified When the previous original resistance value decreases by more ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com