Cylindrical surface fixed-phase pin hole wire cutting tool and method for planetary lead screw

A technology of fixed phase and cylindrical surface, which is applied in the field of wire cutting tooling and wire cutting of cylindrical surface fixed pin hole for planetary screw, which can solve the problem of difficult machining of pin hole of planetary screw nut, difficult guarantee of 90-degree phase angle, insertion High functional requirements of the gear machine, to achieve fast clamping, improved machining accuracy, convenient operation and locking methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings and examples.

[0033] The invention provides a pin hole processing tool and method specially used for tangential phasing requirements on a cylindrical surface.

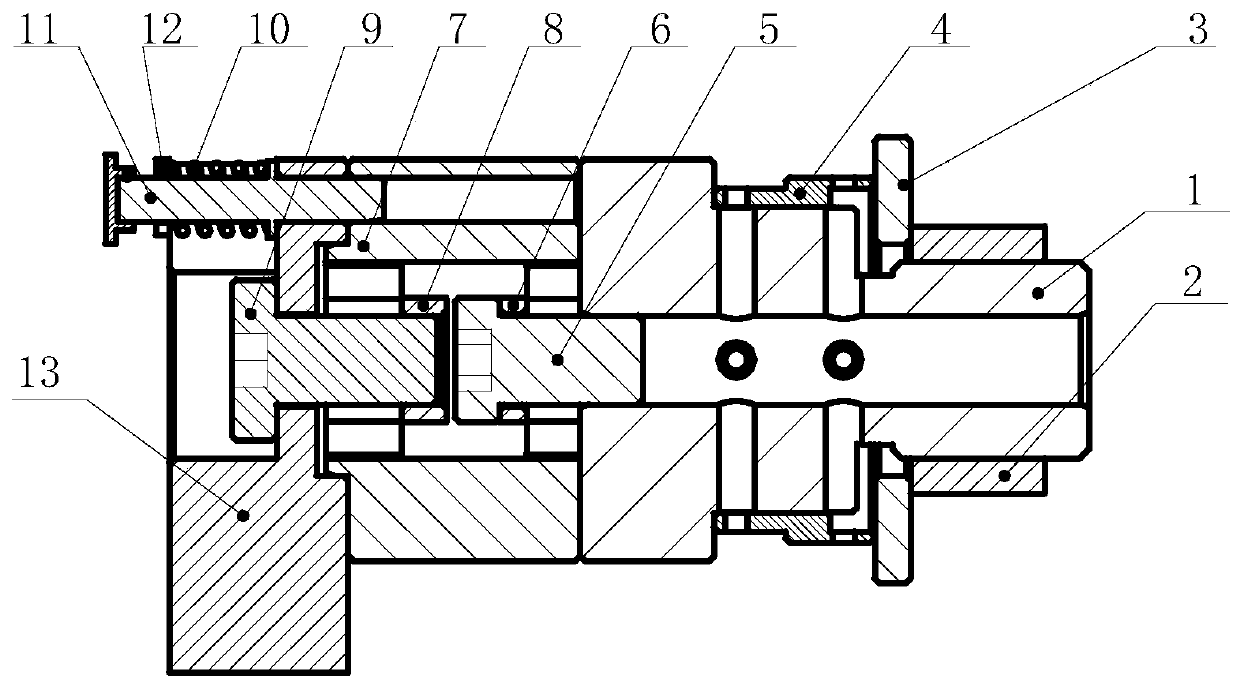

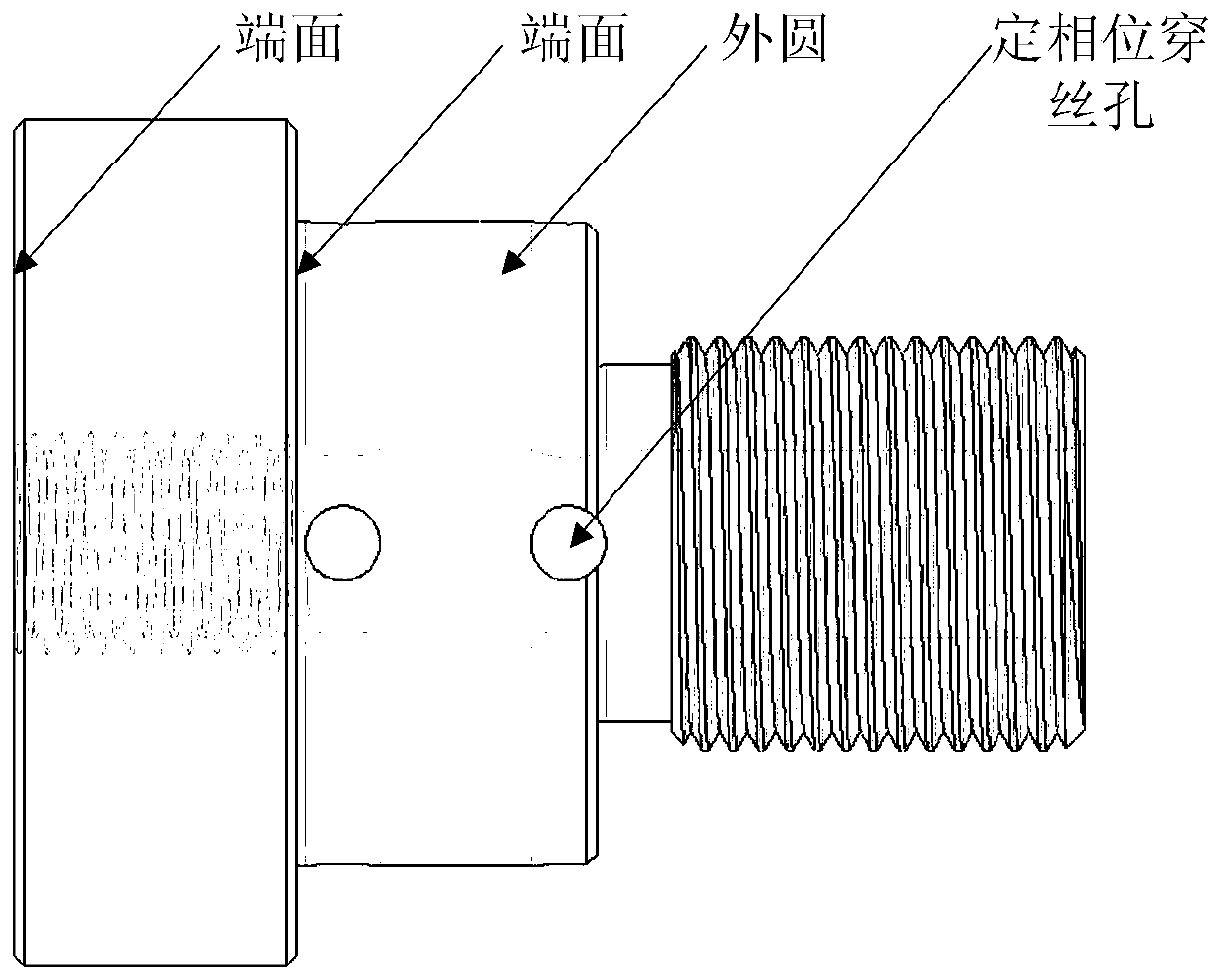

[0034] like figure 1 As shown, the planetary lead screw of the present invention uses a cylindrical surface phase-fixed pin-hole wire-cut tooling including a workpiece fixing frame 1, a transition indexing plate 7 and a fixing bracket 13. The workpiece fixing frame 1 is a three-stage stepped shaft structure, and the middle of the stepped shaft structure is A fixed-phase threading hole is processed on the cylindrical section, and the position of the threading hole is consistent with the position of the phasing pin hole of the workpiece 4; tight. figure 2 Schematic diagram of the workpiece holder.

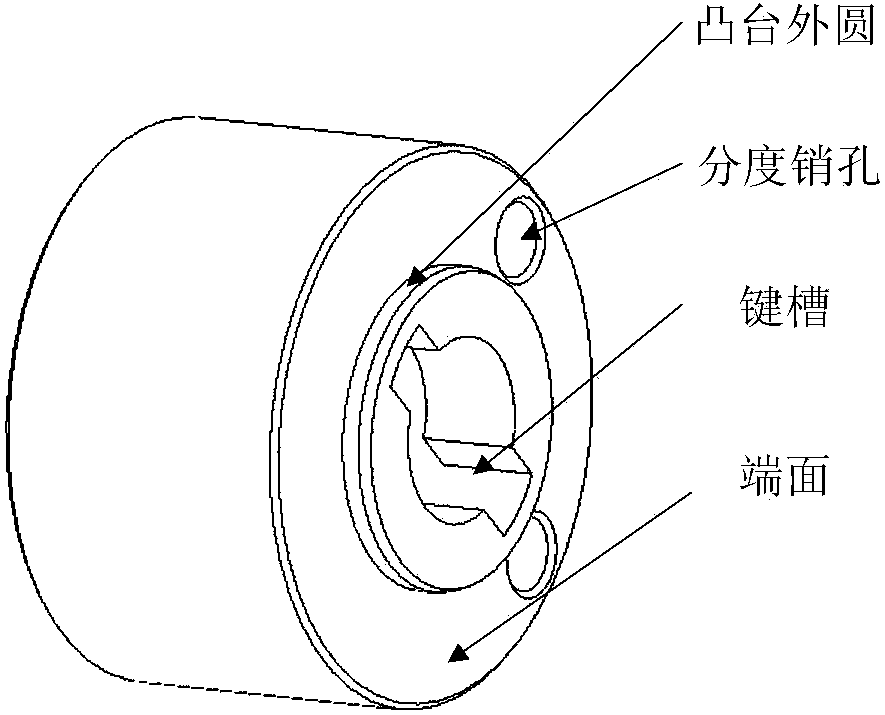

[0035] like image 3 As shown, the transition indexing plate 7 is a ring-shaped structure, one side of the en...

PUM

| Property | Measurement | Unit |

|---|---|---|

| verticality | aaaaa | aaaaa |

| Cylindricity | aaaaa | aaaaa |

| verticality | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com