Strip steel winding temperature control method and device and strip steel machining system

A technology of coiling temperature and strip speed, which is applied in the field of strip coiling temperature control and strip processing system, can solve the problems of excessive coiling temperature difference, etc., and achieve the effect of reducing cutting loss and avoiding excessive difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052]The embodiment of the present application provides a strip steel coiling temperature control method, device and strip steel processing system, which solves the problem in the prior art that the coiling temperature at the tail end of the strip steel is too different from the coiling temperature at the front end due to steel throwing. question.

[0053] The technical solution of the embodiment of the present application is to solve the above-mentioned technical problems, and the general idea is as follows:

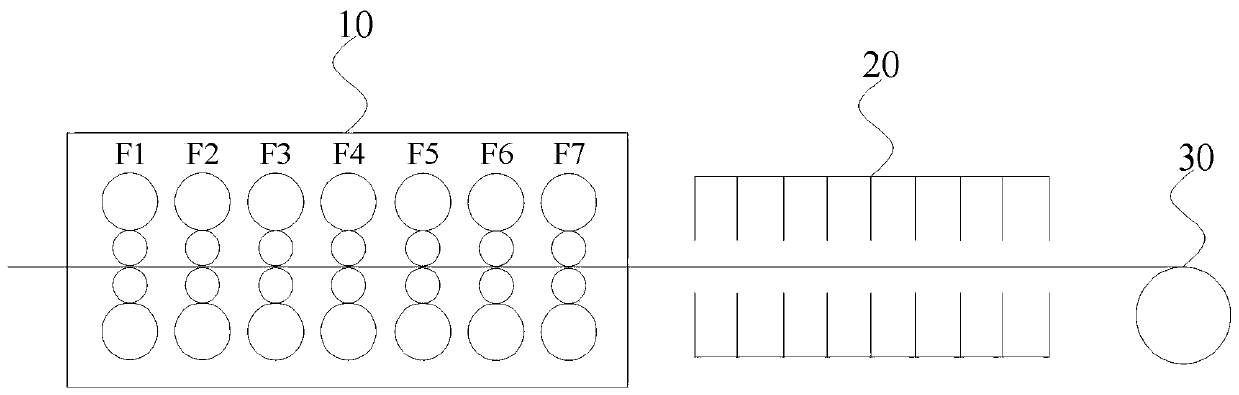

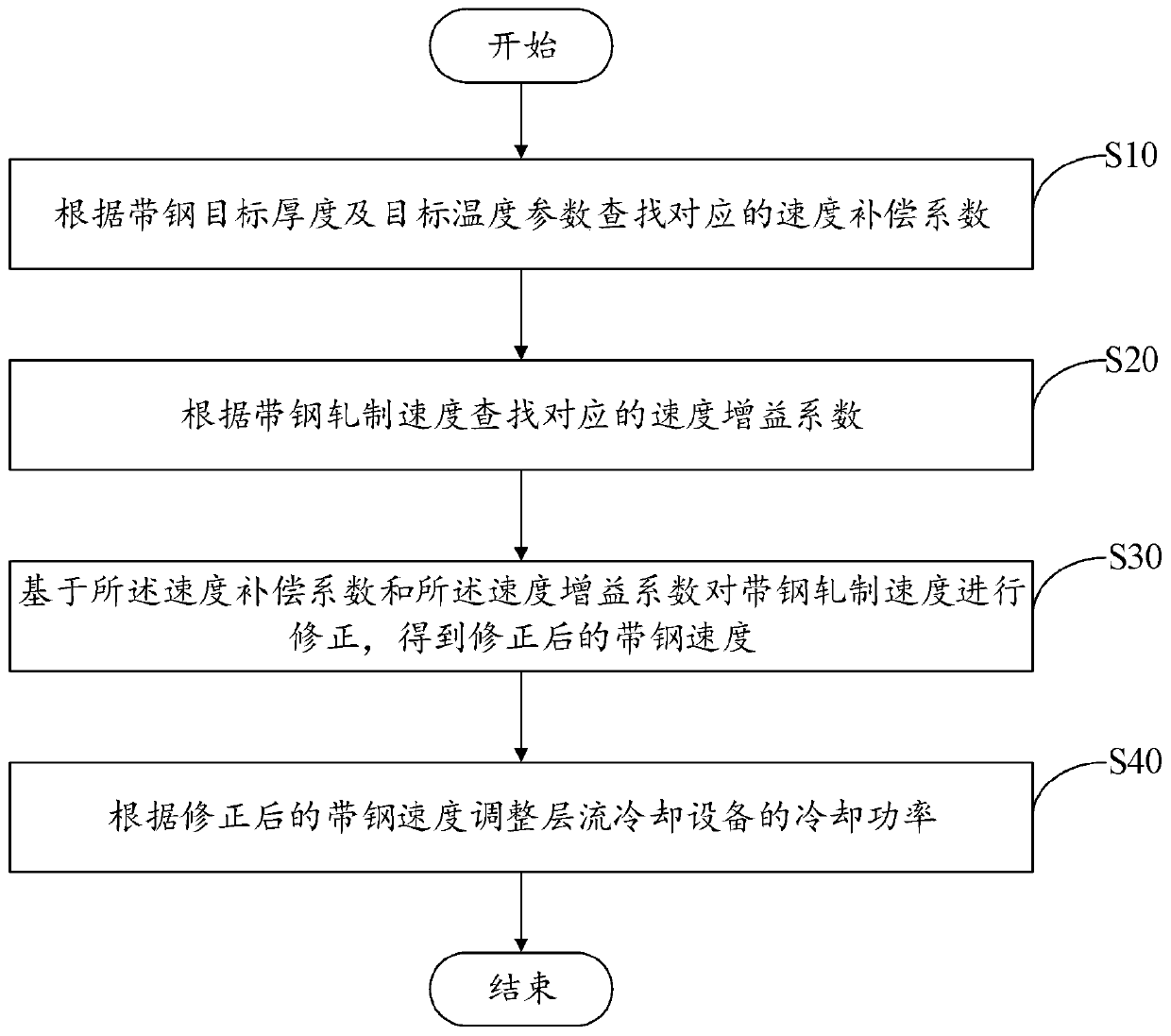

[0054] A strip steel coiling temperature control method, applied to laminar flow cooling equipment, the laminar flow cooling equipment is configured with a first correspondence table and a second correspondence table, wherein the first correspondence table is configured with the target thickness of the strip steel and the speed compensation coefficient corresponding to the target temperature parameter, the second correspondence table is configured with a speed gain coe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com