A Cutting Method for Reducing Cutting Loss of LED Chips

A technology of LED chip and cutting method, which is applied in the manufacture of semiconductor devices, electrical components, semiconductor/solid-state devices, etc., can solve the problems of large loss in the light-emitting area of the chip, increased contact area between the blade back and the surface of the chip, cracking, etc. The effect of cutting loss, improving light extraction efficiency and reducing cutting loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

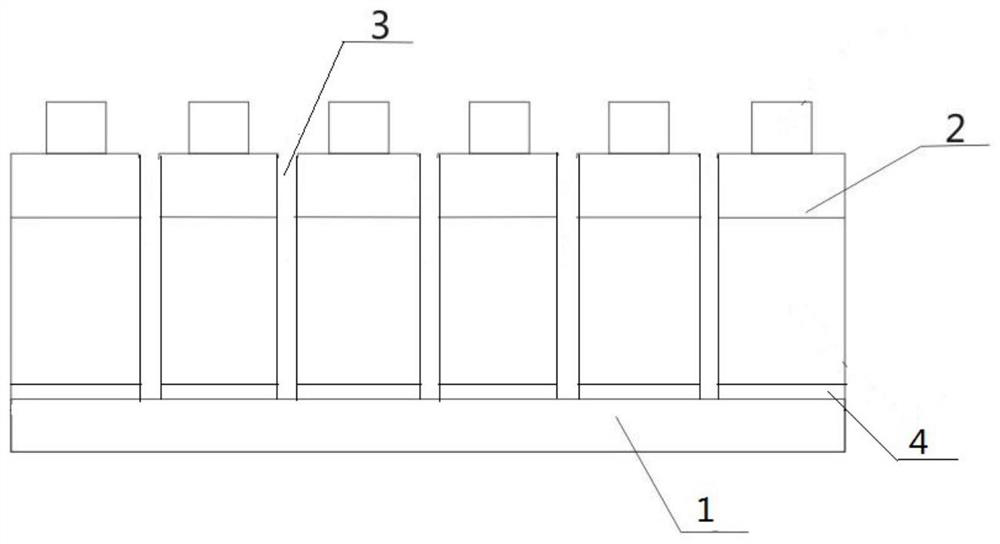

Image

Examples

Embodiment 1

[0064] Step 1: Prepare the LED chip;

[0065] Step 2: Take the prepared LED chip, and cut the P side of the LED chip into half at intervals according to the period set by the process; the cutting depth is 5% of the thickness of the LED chip;

[0066] Step 3: Take the half-cut LED chip and test it with a testing machine. The test current is 20mA, the test time is 5ms, and the corresponding brightness, voltage and wavelength of the LED chip are tested;

[0067] Step 4: Adsorb the tested LED chip on the suction cup of the glue homogenizer, use the glue homogenizer to apply negative glue on the P surface, and form a protective film on the P surface after coating; the speed of the glue homogenizer suction cup is first 2500r / 3000r / min after min, the glue thickness is

[0068] Step 5: Place the glue-coated LED chip on the platform of the photolithography machine for light exposure, and expose the cutting line on the protective film; the light intensity during exposure is 6 μW / cm ...

Embodiment 2

[0079] Step 1: Prepare the LED chip;

[0080] Step 2: Take the prepared LED chip, and cut the P side of the LED chip into half at intervals according to the period set by the process; the cutting depth is 8% of the thickness of the LED chip;

[0081] Step 3: Take the half-cut LED chip and test it with a testing machine. The test current is 20mA, the test time is 5ms, and the corresponding brightness, voltage and wavelength of the LED chip are tested;

[0082]Step 4: Adsorb the tested LED chip on the suction cup of the glue homogenizer, and use the glue homogenizer to apply negative glue on the P surface, and form a protective film on the P surface after the glue is applied; the speed of the glue homogenizer suction cup is first 3000r / 4000r / min after min, the glue thickness is

[0083] Step 5: Place the glue-coated LED chip on the platform of the photolithography machine for light exposure, and expose the cutting line on the protective film; the light intensity during expos...

Embodiment 3

[0094] Step 1: Prepare the LED chip;

[0095] Step 2: Take the prepared LED chip, and cut the P side of the LED chip into half at intervals according to the period set by the process; the cutting depth is 10% of the thickness of the LED chip;

[0096] Step 3: Take the half-cut LED chip and test it with a testing machine. The test current is 20mA, the test time is 5ms, and the corresponding brightness, voltage and wavelength of the LED chip are tested;

[0097] Step 4: Adsorb the tested LED chip on the suction cup of the glue homogenizer, use the glue homogenizer to apply negative glue on the P surface, and form a protective film on the P surface after coating; the speed of the glue homogenizer suction cup is first 4000r / 5000r / min after min, the glue thickness is

[0098] Step 5: Place the glue-coated LED chip on the platform of the photolithography machine for light exposure, and expose the cutting line on the protective film; the light intensity during exposure is 10μW / cm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com