High-flux liquid-liquid extraction microfluidic device and extraction method thereof

A microfluidic device and high-throughput technology, applied in liquid solution solvent extraction, separation methods, countercurrent extraction, etc., can solve problems that are not suitable for continuous large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

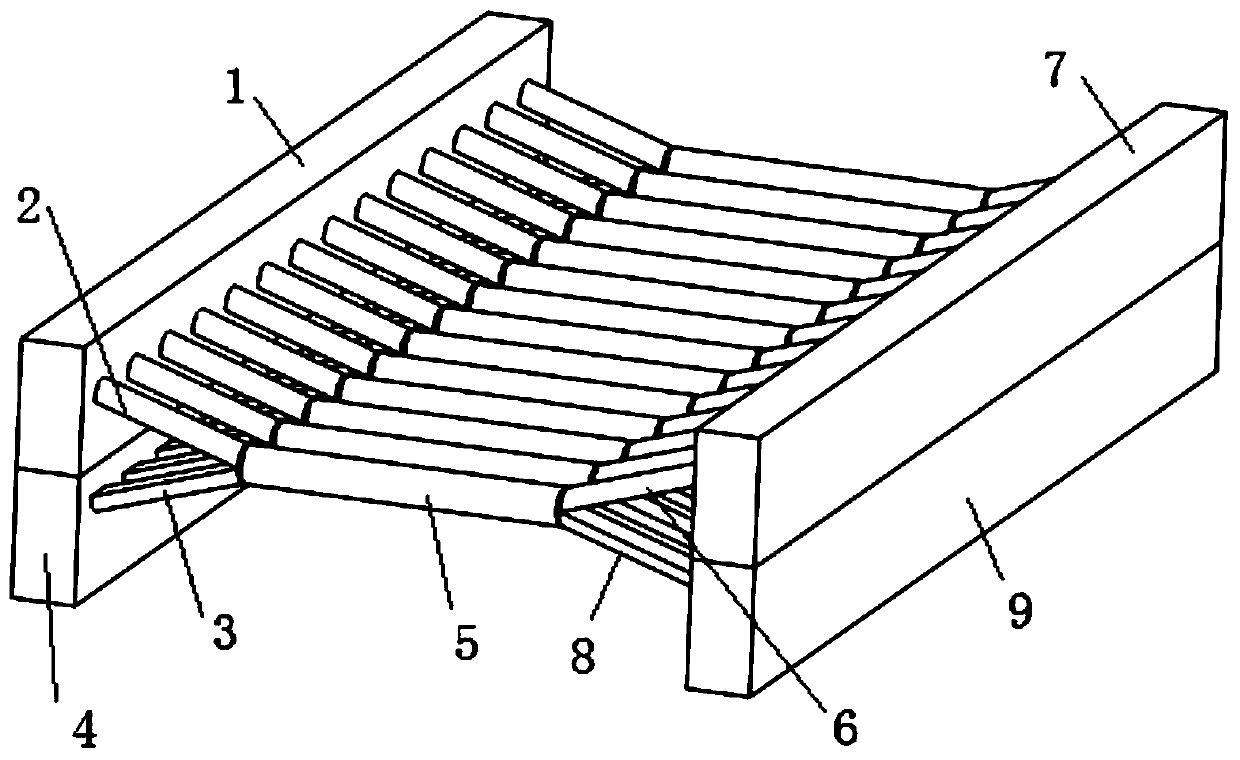

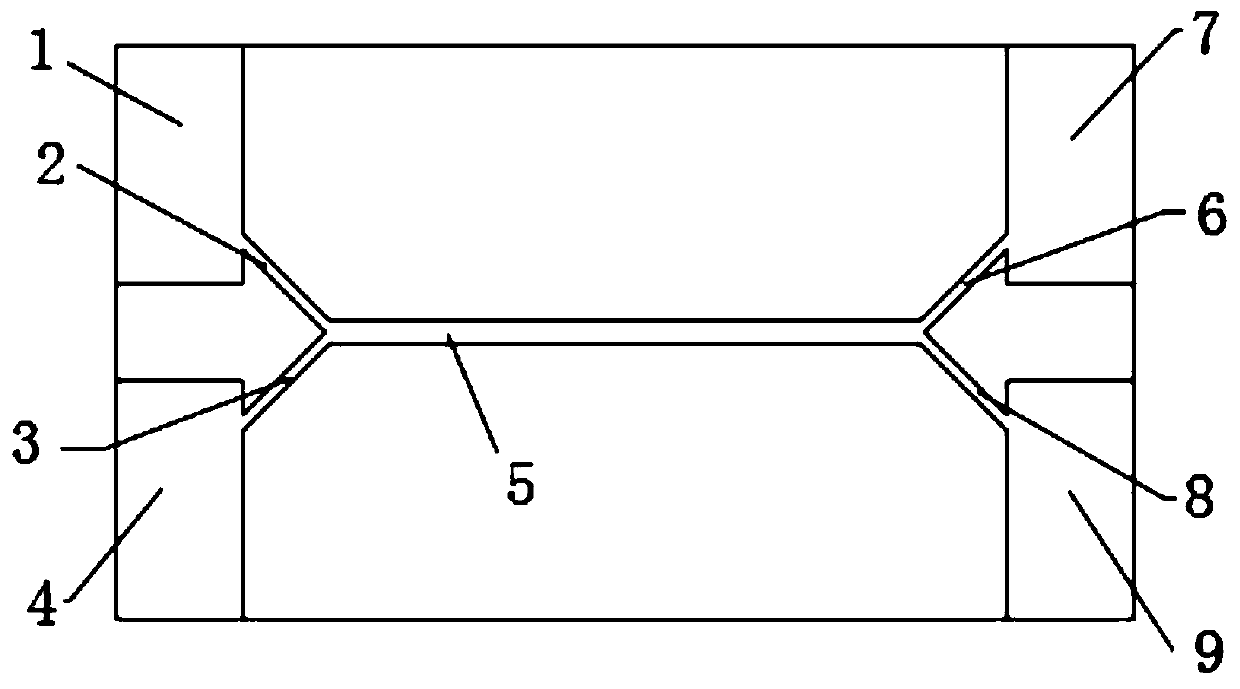

[0033] In this embodiment, copper ions are extracted in the same direction.

[0034] The prepared copper ion solution is stored in the water phase inlet liquid collection chamber 4, the extractant is stored in the oil phase inlet liquid collection chamber 1, and pressurized simultaneously, the water phase (copper ion solution) and the oil phase (extractant) Enter the contact extraction microchannel 5 through the water phase inlet microchannel 3 and the oil phase inlet microchannel 2 respectively. After the extraction, the extractant containing copper ions flows into and is stored in the oil phase outlet liquid collection cavity 7 through the oil phase outlet microchannel 6, and the extracted copper ion solution flows into and is stored in the liquid phase outlet collection chamber 8 through the water phase outlet microchannel 8. In the liquid chamber 9.

[0035] At the beginning, the water phase (copper ion solution after extraction) and the oil phase (containing The extract...

Embodiment 2

[0037] In this embodiment, reverse extraction of copper ions of copper ions is carried out.

[0038] The positions of the oil phase inlet liquid collection chamber 1 and the oil phase outlet liquid collection chamber 7 are exchanged. The prepared copper ion solution is stored in the liquid collection chamber 4 at the inlet of the water phase, and the extractant is stored in the liquid collection chamber 1 at the inlet of the oil phase. First pressurize the water phase inlet liquid collection chamber 4, and the copper ion solution enters the contact extraction microchannel 5 through the water phase inlet microchannel 3. After the flow rate of the copper ion solution is stable, pressurize the oil phase inlet liquid collection chamber 1, so that the extractant enters the contact extraction microchannel 5 through the oil phase inlet microchannel 2. After the extraction, the extractant containing copper ions flows into and is stored in the oil phase outlet liquid collection cavity...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Average height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com